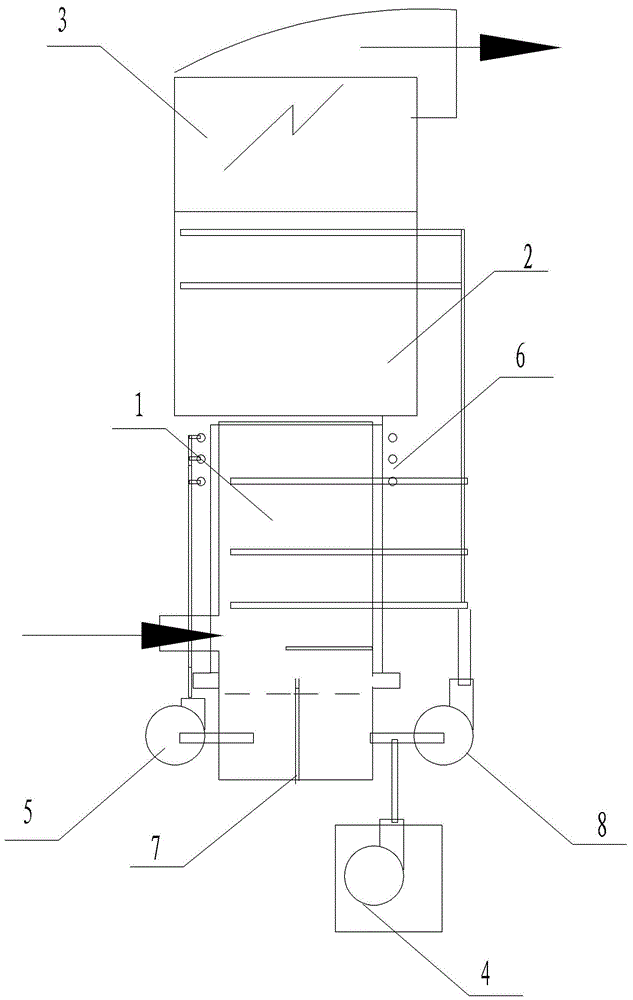

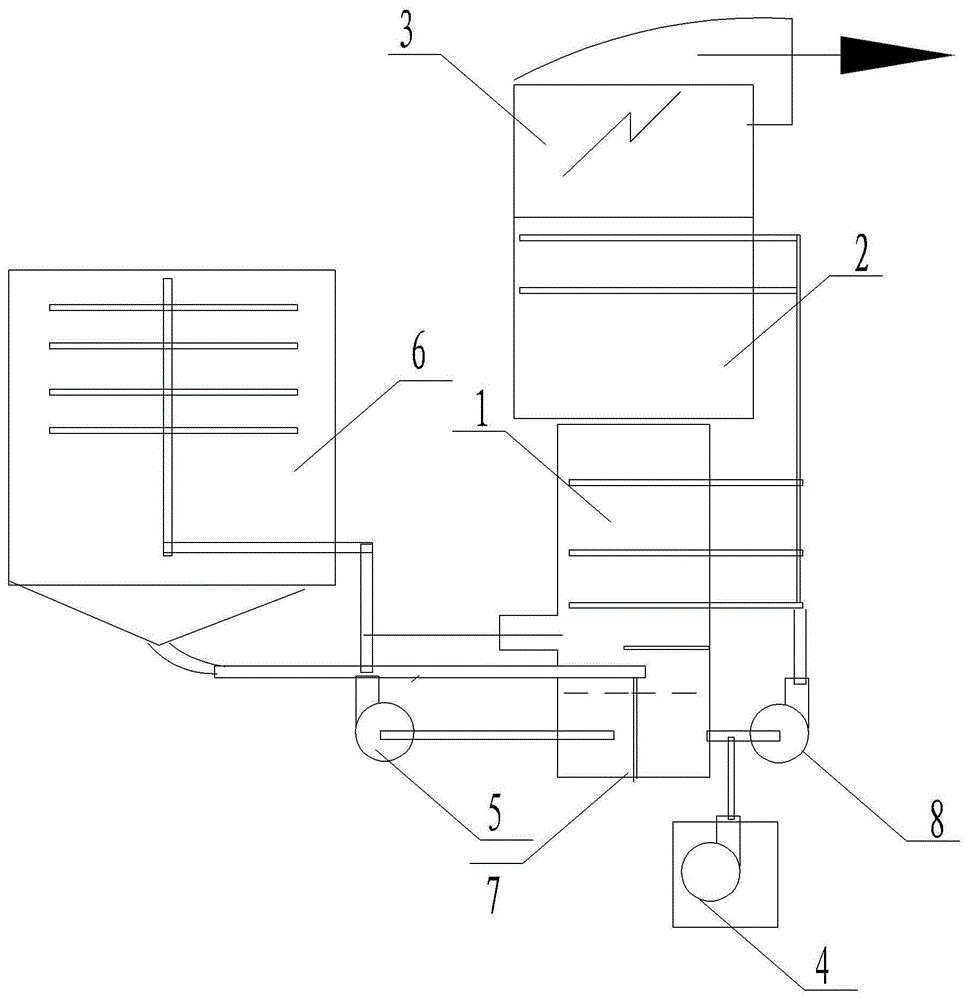

Wet desulfurization equipment for coal fired boiler

A technology for wet desulfurization and coal-fired boilers, which is applied in separation methods, chemical instruments and methods, combined devices, etc., can solve problems such as imperfect wet desulfurization technology and unbalanced total sulfur intake and discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Example: 300,000 units, 1,080-ton boiler.

[0045] Flue gas flow: 1.2 million cubic meters per hour.

[0046] After dust removal, the smoke concentration is greater than 400mg / m 3 .

[0047] After dedusting, the flue gas at about 150 degrees enters the desulfurization tower through the fan.

[0048] Effect: Discharge colorless and transparent flue gas from the top of the electrostatic tower, the demisting efficiency is close to 100%, the dust removal efficiency is close to 100%, the soot emission concentration is less than 5 mg / m3, and the gaseous SO 2 The removal efficiency is close to 100%, SO 2The emission concentration is less than 10 mg / m3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com