Batch reactor with baffle

A technology of reactors and spoilers, applied in mixers with rotary stirring devices, chemical/physical/physical-chemical stationary reactors, detailed information of chemical/physical/physical-chemical reactors, etc., can solve the problem of stirring paddles. The blade size cannot be increased, the temperature control performance of the spoiler is deteriorated, and the heat transfer area of the spoiler is reduced, so as to improve the eddy current and mixing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention.

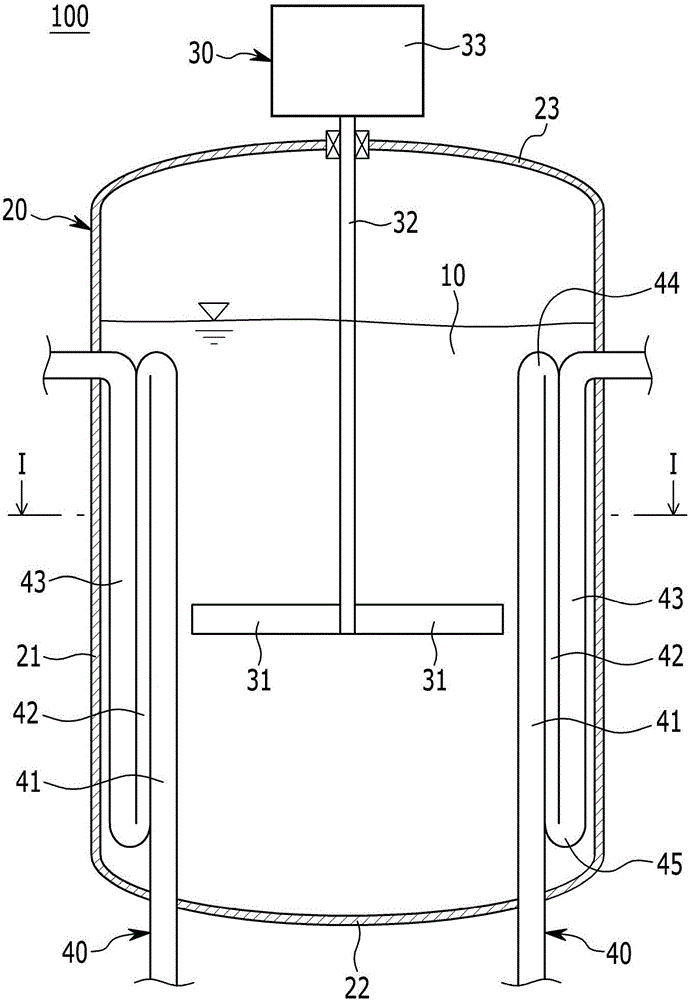

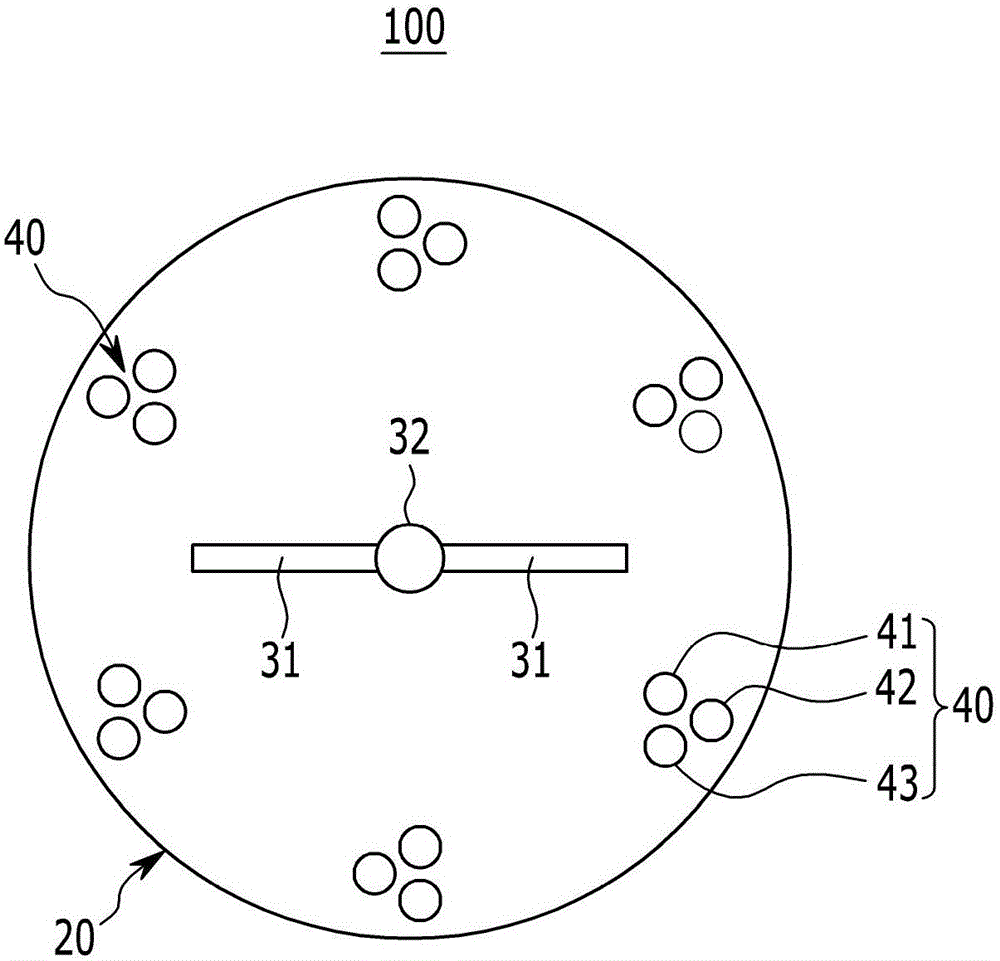

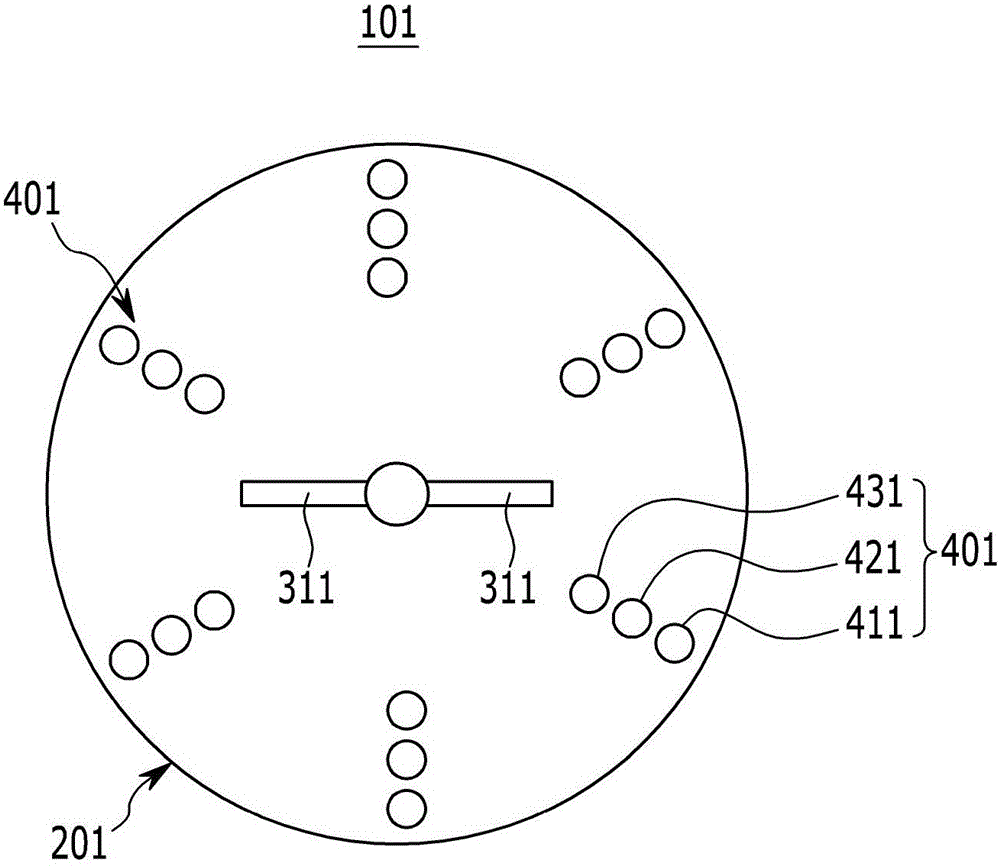

[0023] figure 1 is a schematic diagram of a batch reactor according to the first exemplary embodiment of the present invention, and figure 2 Yes figure 1 Schematic cross-section along line I-I.

[0024] refer to figure 1 and figure 2 , the batch reactor 100 according to the first exemplary embodiment of the present invention includes a reactor body 20 for containing reactants 10, a stirring blade 31 arranged in the reactor body 20 to rotate the reactants 10, and stirring The rotation shaft 32 of the paddle 31 is connected to a motor 33 for rotating the stirring paddle 31 , and a plurality of spoilers 40 provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com