A Scene Simulator with Rotating Reticle

A scene simulation and reticle technology, applied in the field of scene simulators, can solve the problems of shutting down equipment, complicated testing process, and rising instrument cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

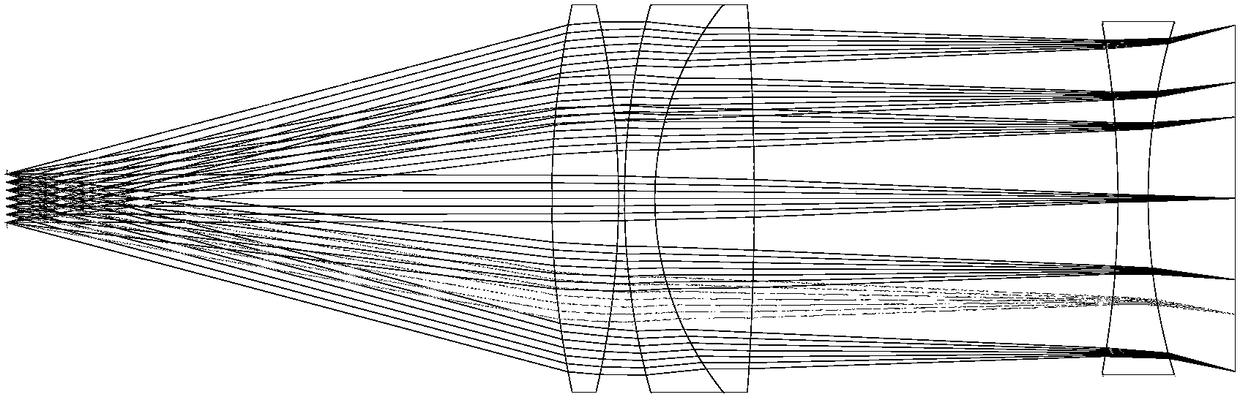

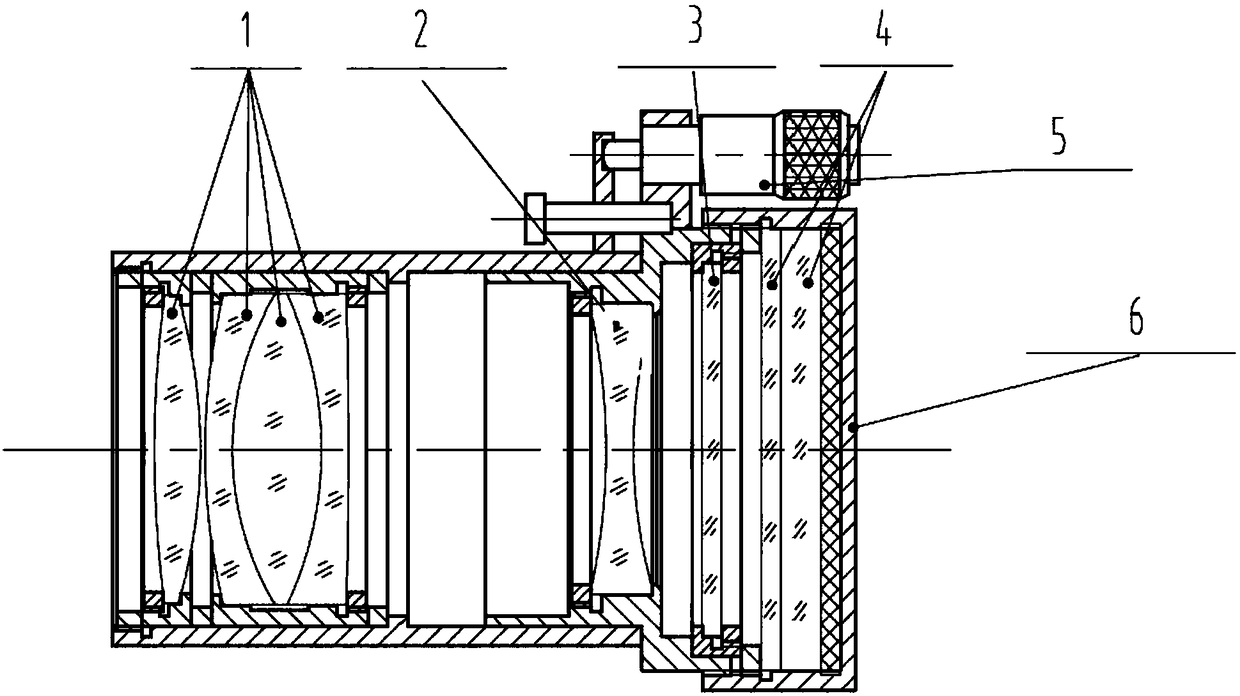

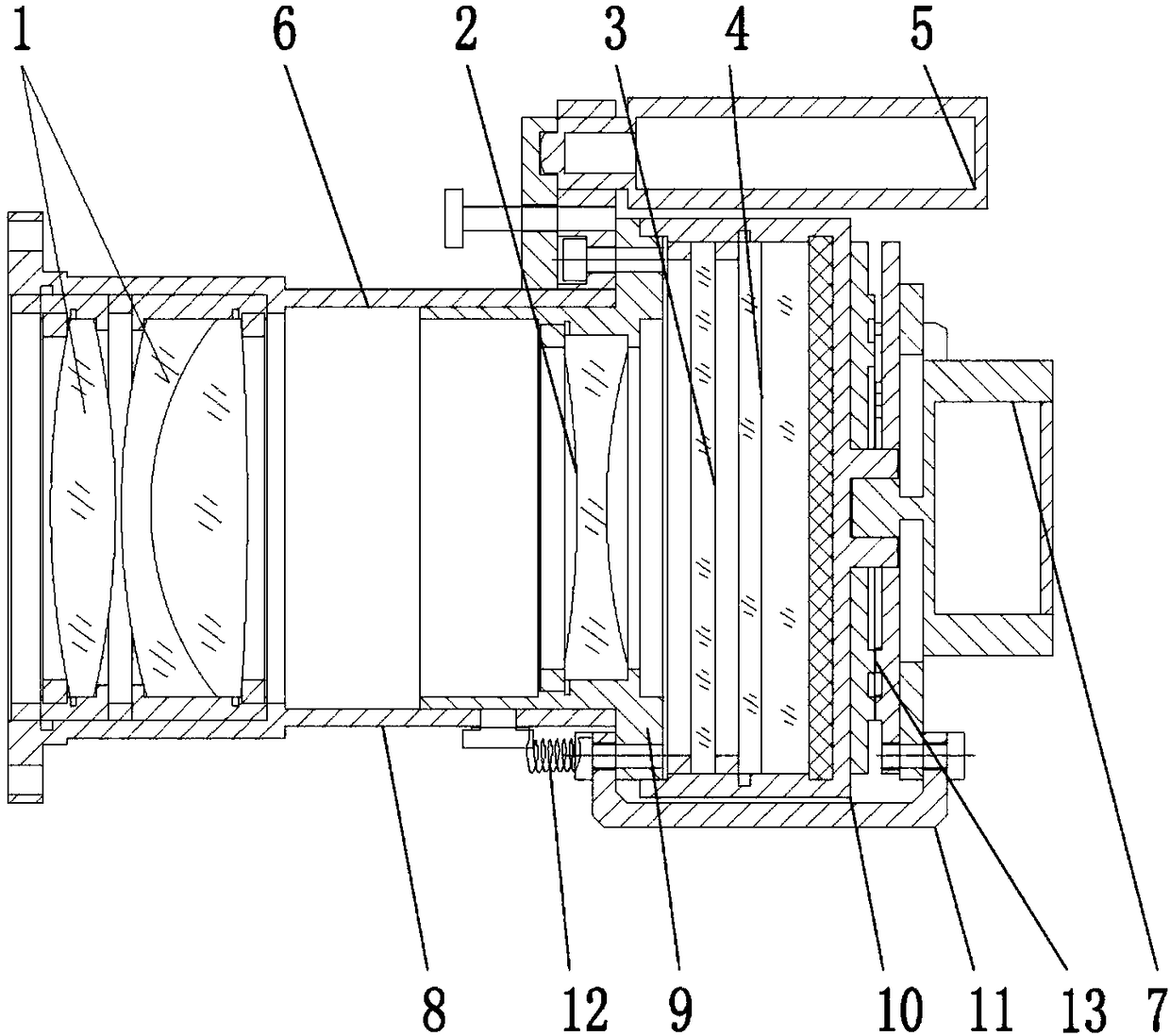

[0031] see image 3 , 4 , 5. The present invention provides a scene simulator with a rotatable reticle, including an objective lens assembly 1, a reticle 3, a light source 4, an image quality compensation mirror 2, and a mechanical support structure 6;

[0032] The objective lens assembly 1, the image quality compensation mirror 2, the reticle 3, and the light source 4 are all arranged inside the mechanical support structure 5; the image quality compensation mirror 2 is arranged in front of the focal plane of the objective lens assembly 1; the reticle 3 is arranged on the objective lens assembly 1 on the focal plane; the light source 4 is arranged directly behind the reticle 3; wherein, the relative position of the image quality compensation mirror 2 and the reticle 3 remains unchanged, and the distance between the image quality compensation mirror 2 and the objective lens assembly 1 can be adjusted ;The basic structure above can simulate objects with a distance of 0.5m to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com