Solid enzyme type time-temperature indicator

A technology of temperature indicators and enzymes, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problem of less TTI, etc., and achieve the effects of low cost, stable reaction, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

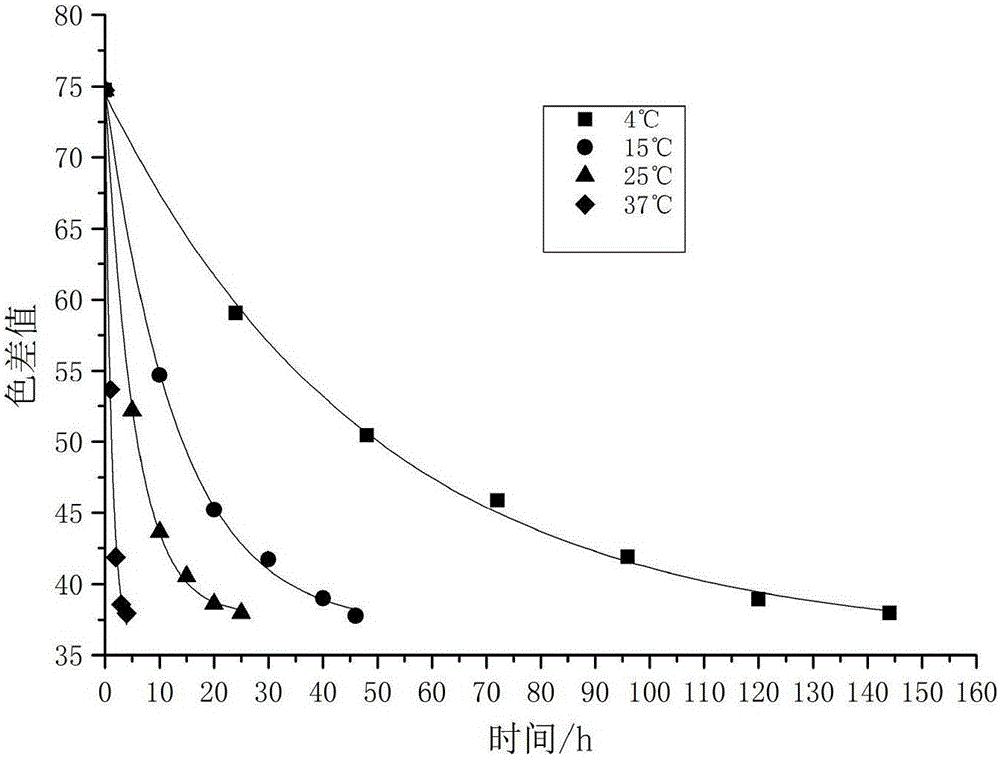

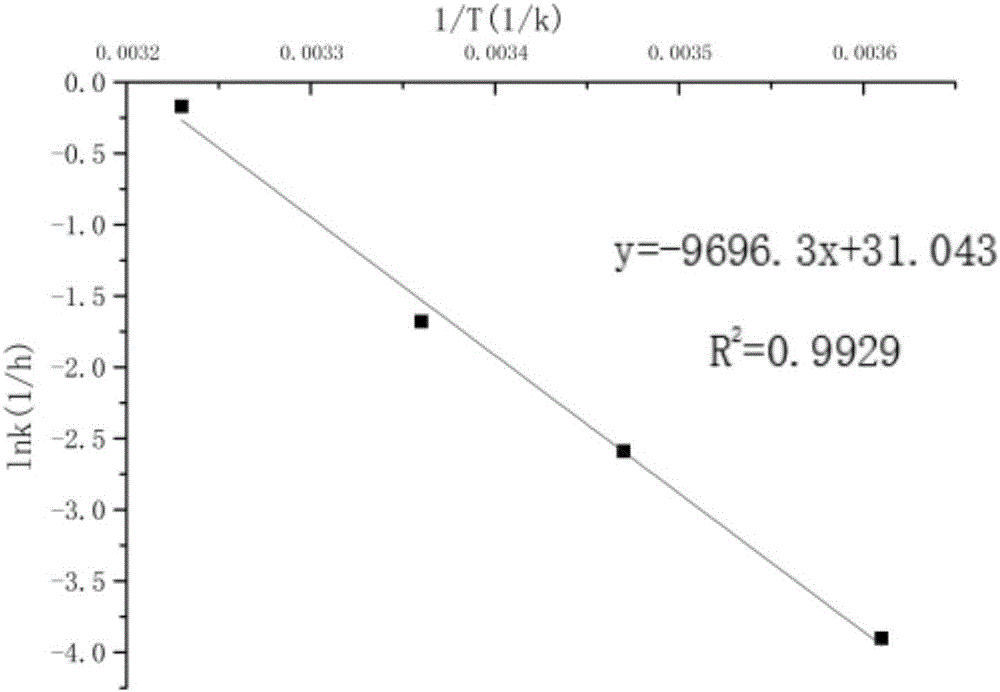

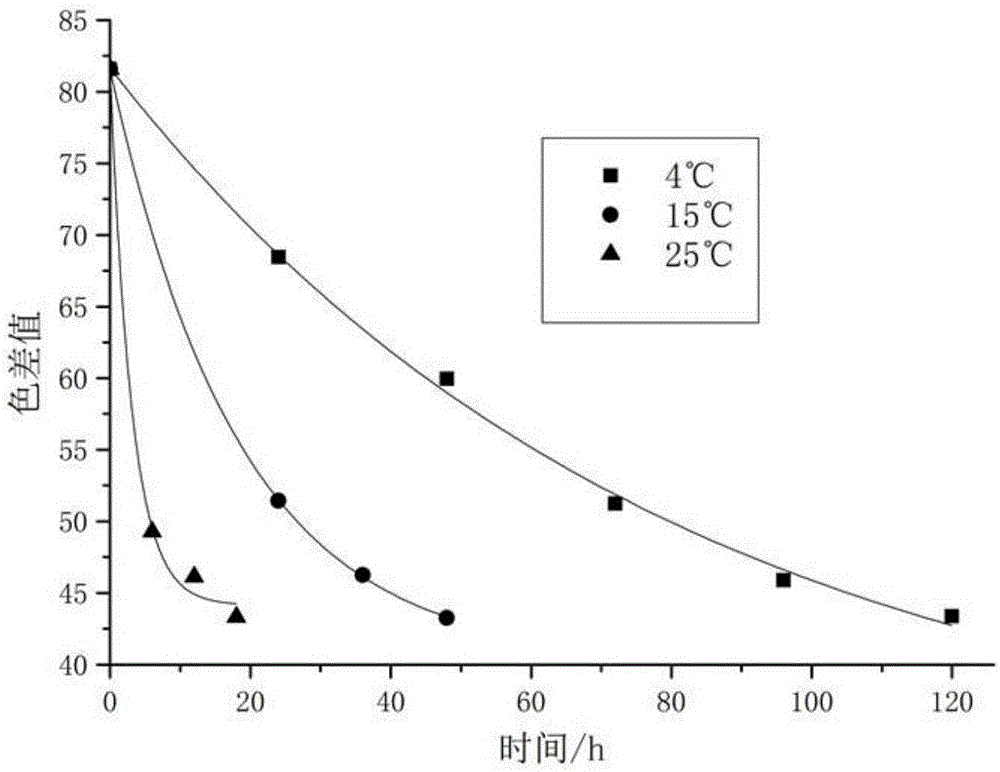

Method used

Image

Examples

Embodiment 1

[0014] (1) Preparation of discolored starch: Take 10g of soluble starch, add 5ml of 0.1mol / L iodine solution, mix evenly and put it in an oven at 54°C to dry until the final water content is less than 2%, crush it with a pulverizer to obtain discolored starch .

[0015] (2) Microencapsulation of glucoamylase: take 0.75g of chitosan, dissolve it in 100ml of 0.5% acetic acid solution, and then add 2.22g of calcium chloride to obtain a chitosan mixed solution for later use. Take 2g of sodium alginate, prepare 2% sodium alginate solution, add 0.1g of solid glucoamylase after cooling off, drop into the chitosan mixed solution with a syringe, put the obtained rubber beads into an oven at 37°C, dry them and crush them.

[0016] (3) Preparation of agar cover plate: take 3g of agar powder, prepare 3% agar solution, pour it into a container of a certain shape while it is hot, put it in the refrigerator for later use after cooling and solidifying.

[0017] (4) Production of indicator: p...

Embodiment 2

[0019] (1) Preparation of discolored starch: Take 10g of soluble starch, add 7ml of 0.1mol / L iodine solution, mix evenly and put it in a 54°C oven to dry until the final water content is less than 2%, and pulverize it with a pulverizer to obtain discolored starch .

[0020] (2) Microencapsulation of glucoamylase: take 0.75g of chitosan, dissolve it in 100ml of 0.5% acetic acid solution, and then add 2.22g of calcium chloride to obtain a chitosan mixed solution for later use. Take 2g of sodium alginate, prepare 2% sodium alginate solution, add 0.1g of solid glucoamylase after cooling off, drop into the chitosan mixed solution with a syringe, put the obtained rubber beads into an oven at 37°C, dry them and crush them.

[0021] (3) Preparation of agar cover plate: take 3g of agar powder, prepare 3% agar solution, pour it into a container of a certain shape while it is hot, put it in the refrigerator for later use after cooling and solidifying.

[0022] (4) Production of indicato...

Embodiment 3

[0024] (1) Preparation of discolored starch: take 10g of soluble starch, add 10ml of 0.1mol / L iodine solution, mix well and put it in a 54°C oven to dry until the final water content is less than 2%, and pulverize with a pulverizer to obtain discolored starch .

[0025] (2) Microencapsulation of glucoamylase: take 0.75g of chitosan, dissolve it in 100ml of 0.5% acetic acid solution, and then add 2.22g of calcium chloride to obtain a chitosan mixed solution for later use. Take 2g of sodium alginate, prepare 2% sodium alginate solution, add 0.1g of solid glucoamylase after cooling off, drop into the chitosan mixed solution with a syringe, put the obtained rubber beads into an oven at 37°C, dry them and crush them.

[0026] (3) Preparation of agar cover plate: take 3g of agar powder, prepare 3% agar solution, pour it into a container of a certain shape while it is hot, put it in the refrigerator for later use after cooling and solidifying.

[0027] (4) Production of indicator: P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com