A scraper conveyor sprocket tooth wear monitoring device and method

A scraper conveyor and monitoring device technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of jumping teeth, no mature detection of sprocket tooth wear, and sprocket tooth breakage. Avoid the effect of abnormal equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings.

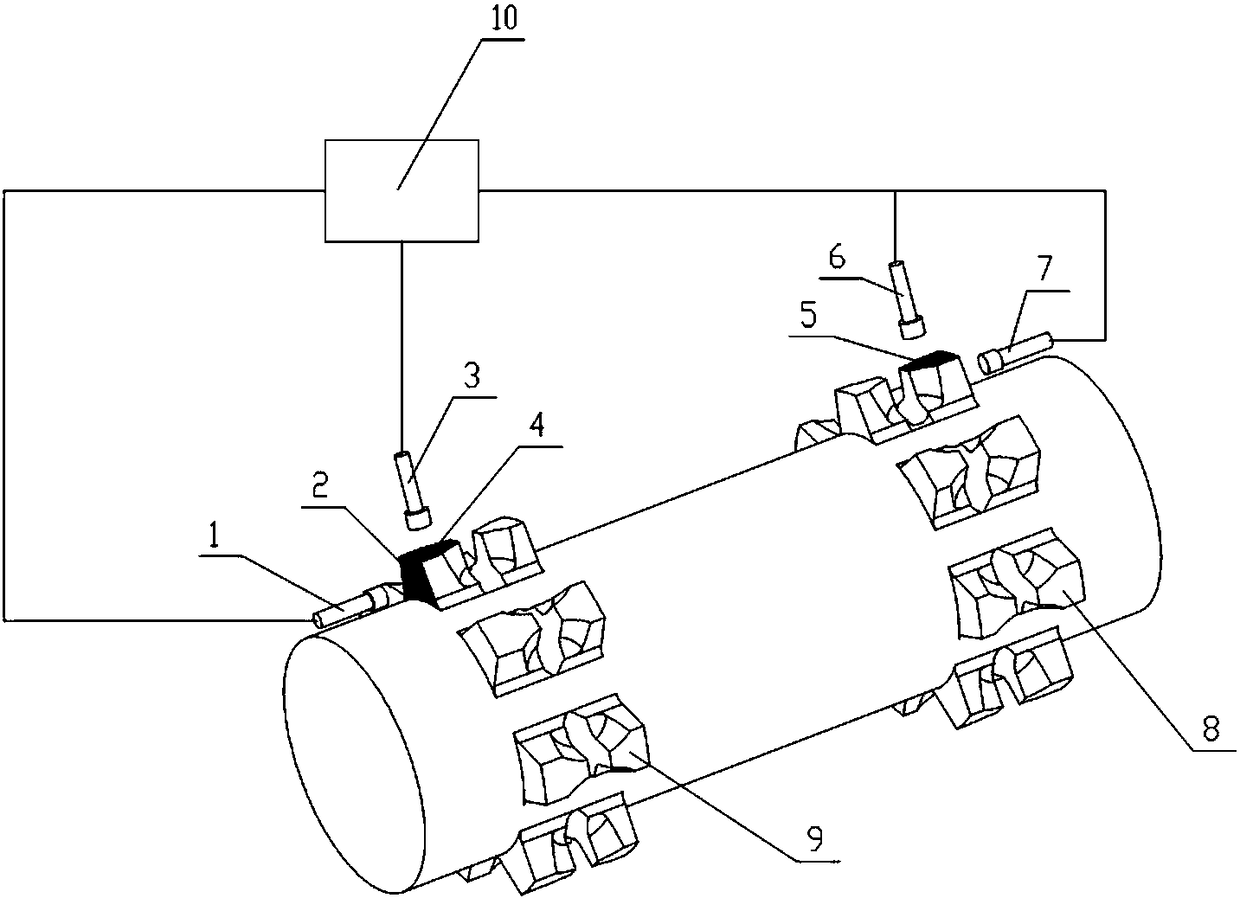

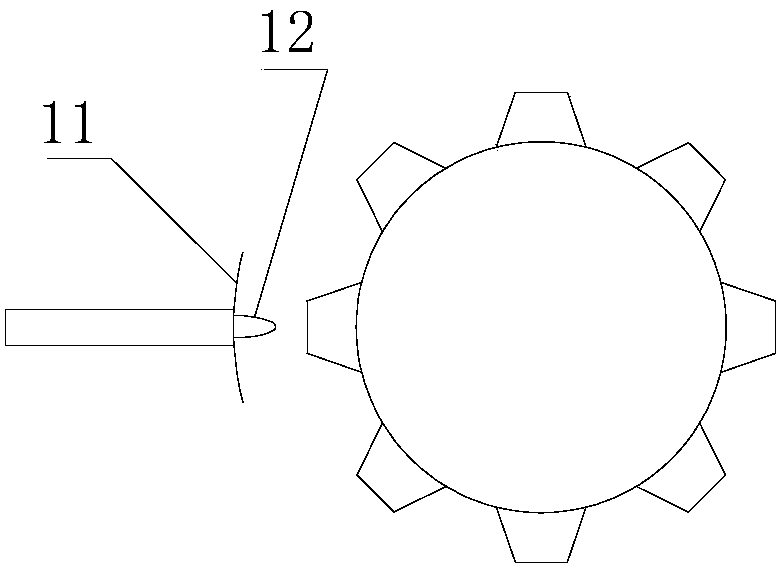

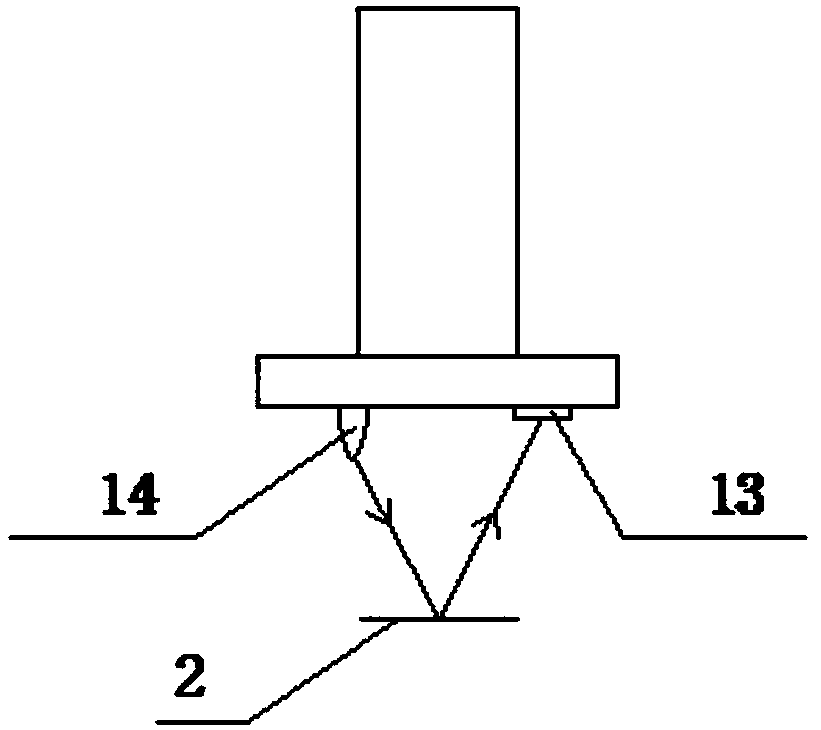

[0025] Such as figure 1 , 2 , 3 and 4, a scraper conveyor sprocket tooth wear monitoring device of the present invention includes: a top reflective patch, a vertical photoelectric sensor module, a side reflective patch, a horizontal photoelectric sensor module and a data analysis module.

[0026] The top reflective patch is installed on the top surface of the sprocket wheel. The top reflective patch is consistent with the shape of the top surface of the sprocket wheel. The vertical photoelectric sensor module includes a vertical light source and a vertical photoelectric sensor element. The vertical light source is a point light source. The light source is used to emit light to the top reflective patch, the vertical photoelectric sensing element is arc-shaped, and the vertical photoelectric sensing element is used to sense the light reflected back from the top reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com