Tamping plug for blasting engineering

A technology of blasting engineering and mud plugs, which is applied in the field of mud plugs, can solve the problems of difficulty in obtaining materials, complicated manufacture of mud plugs, and increased resistance of mud plugs, so as to increase the time for blocking blast holes and reduce explosives Consumption amount, explosive reaction full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

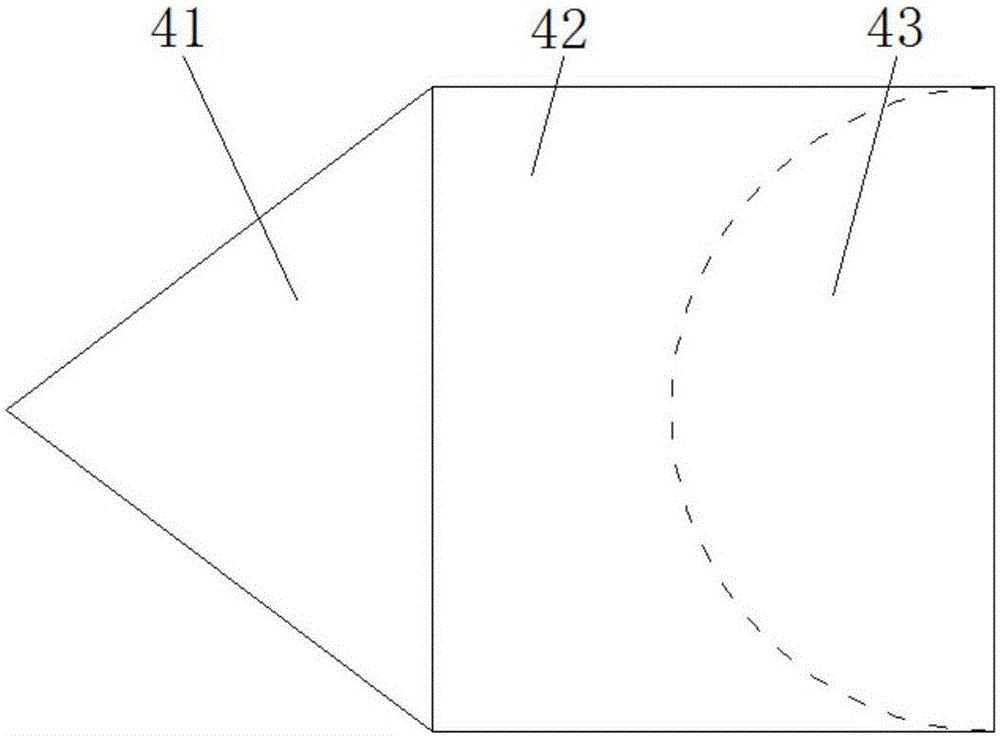

[0020] see figure 2 , adopt the method for plugging blast hole provided by the invention, comprising the following steps:

[0021] (1) drilling to form blast hole 1, after which explosives 2 are loaded into blast hole 1;

[0022] (2) Load the detonator 3 and lead out the detonator leg 6;

[0023] (3) The concave arc portion of the clay plug 4 is inserted into the blast hole against the blast hole;

[0024] (4) Block the taphole clay 5 and compact it.

Embodiment 2

[0026] see image 3 , adopt the method for plugging blast hole provided by the invention, comprising the following steps:

[0027] (1) drilling to form blast hole 1, after which explosives 2 are loaded into blast hole 1;

[0028] (2) Load the detonator 3 and lead out the detonator leg 6;

[0029] (3) The concave arc portion of the first clay plug 4 is inserted into the blast hole against the blast hole;

[0030] (4) plugging the gun mud 5 with a length of 5-8cm;

[0031] (5) The concave arc-shaped portion of the second clay plug 4 is inserted into the blast hole against the blast hole;

[0032] (6) Block the blasthole clay 5 again and compact it.

[0033] This optimization scheme is suitable for occasions with high blasting safety requirements, such as urban demolition blasting and coal mine blasting.

Embodiment 3

[0035] see Figure 4 , adopt the method for plugging blast hole provided by the invention, comprising the following steps:

[0036] (1) drilling to form blast hole 1, after which explosives 2 are loaded into blast hole 1;

[0037] (2) Load the detonator 3 and lead out the detonator leg 6;

[0038] (3) pack into closed water bag 7;

[0039] (4) The concave arc portion of the clay plug 4 is inserted into the blast hole against the blast hole;

[0040] (5) Block the blasthole clay 5 and compact it.

[0041] This optimization scheme is suitable for occasions that require a high concentration of blasting dust, urban demolition blasting, and places where ventilation is unfavorable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com