Heat-preserving device for machining of energy-saving type aluminum materials

A heat preservation device and energy-saving technology, which is applied in furnace types, lighting and heating equipment, crucible furnaces, etc., can solve problems such as unsatisfactory fusion effect of aluminum liquid and ingredients, unsatisfactory heat preservation performance, and high energy consumption of heat preservation furnaces. Improve utilization rate and energy saving, improve thermal insulation effect, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

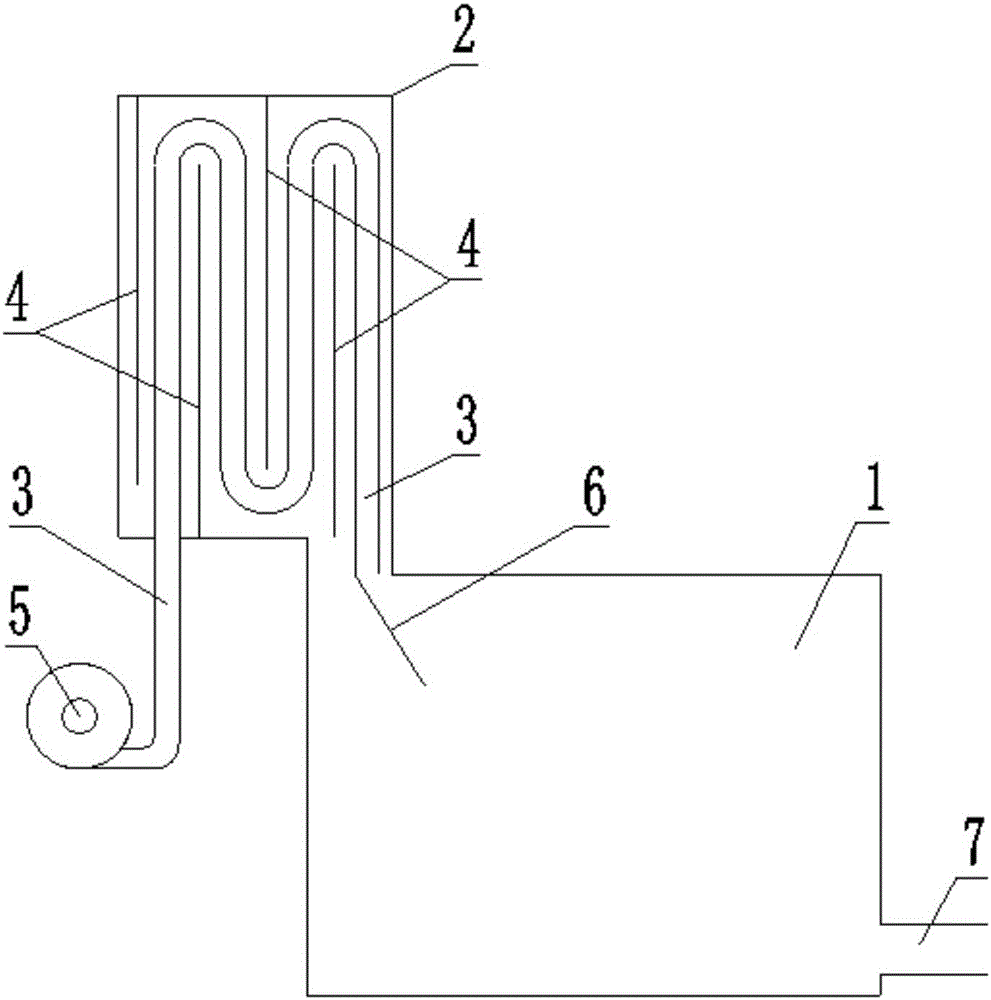

[0012] Example. An energy-saving heat preservation device for processing aluminum materials, which is composed of figure 1 As shown, the holding furnace 1 is included, and the top of the holding furnace 1 is connected with a heat collecting device 2; the heat collecting device 2 is provided with an "S"-shaped air inlet pipe 3 and a plurality of heat collecting plates 4, and the air inlet pipe 3 and the heat collecting plates 4 are arranged in a staggered manner; one end of the air intake pipe 3 is connected to a hot air blower 5 , and the other end of the air intake pipe 3 is connected to a wind deflector 6 .

[0013] The air deflector 6 is arranged obliquely, and the air deflector 6 is located in the holding furnace 1; the holding furnace 1 is connected to the heat collecting device 2; the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com