Cooling structure of continuously variable transmission

A continuously variable transmission and cooling structure technology, applied in gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve the limitation of cooling air discharge, it is difficult to improve the cooling effect of belt-type continuously variable transmission, and it is difficult to form Problems such as air exhaust outlets, to achieve the effect of suppressing the increase of assembly process, suppressing the increase of weight, and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088]Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, the directions of front, rear, left, right, up, and down are based on the driver seated in the saddle-ride vehicle.

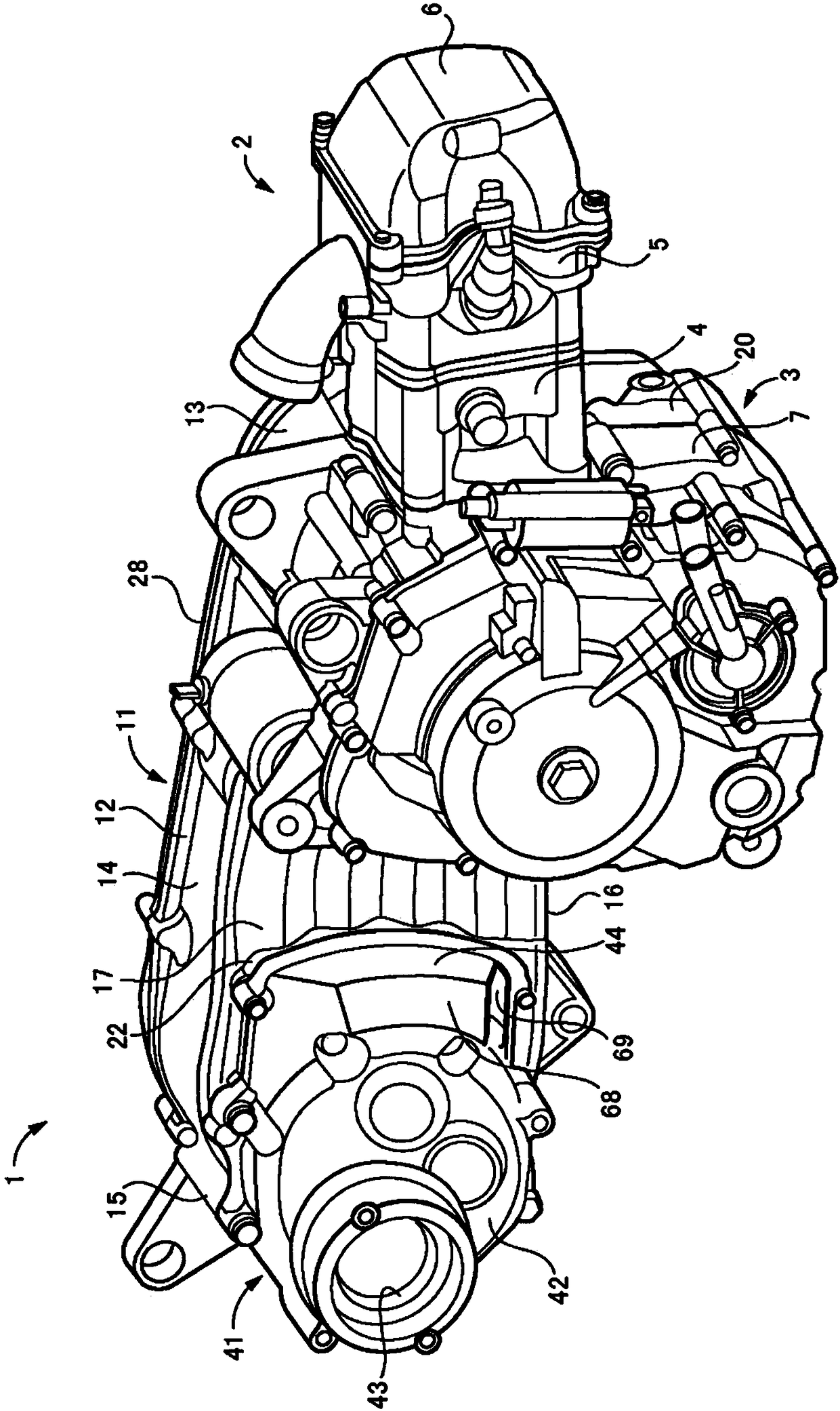

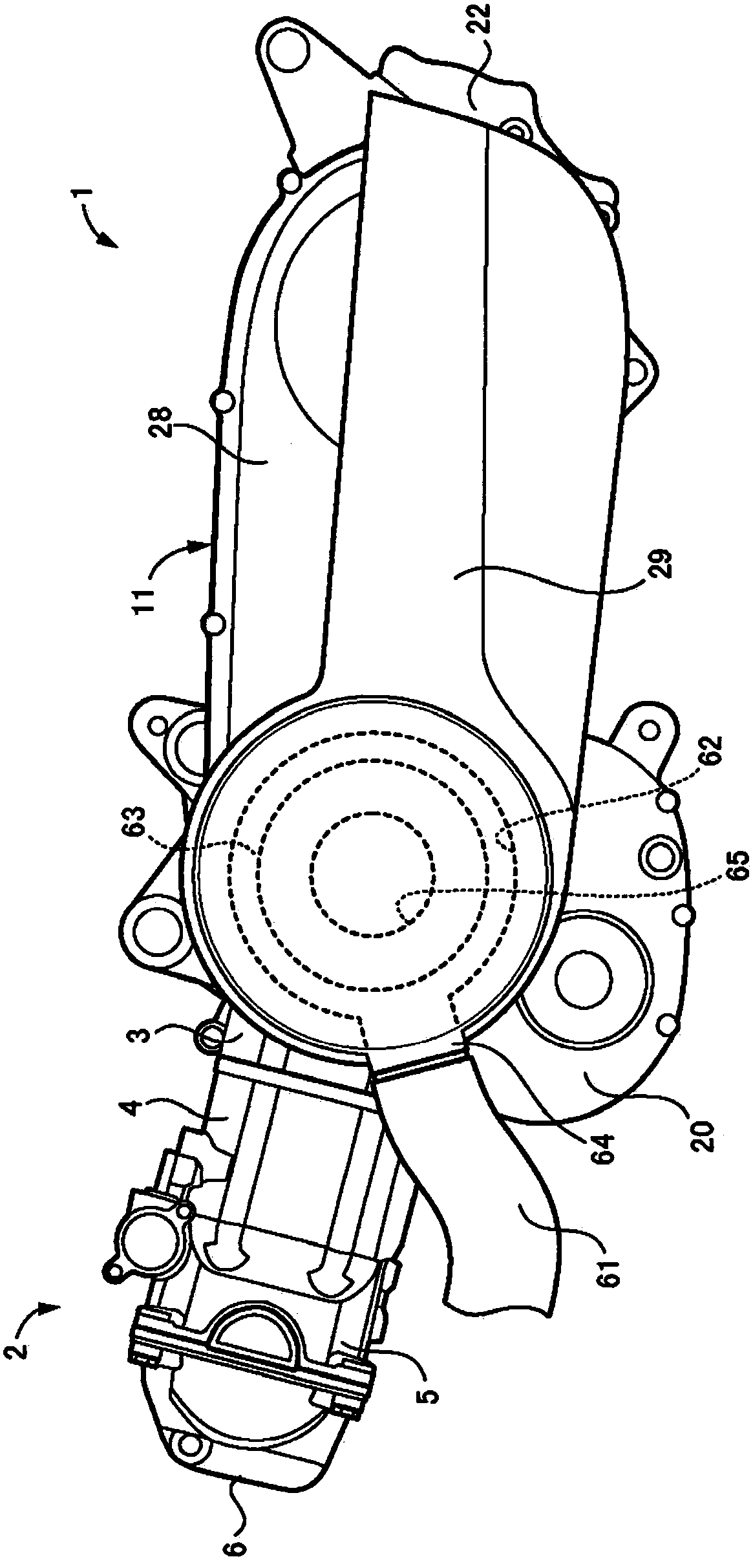

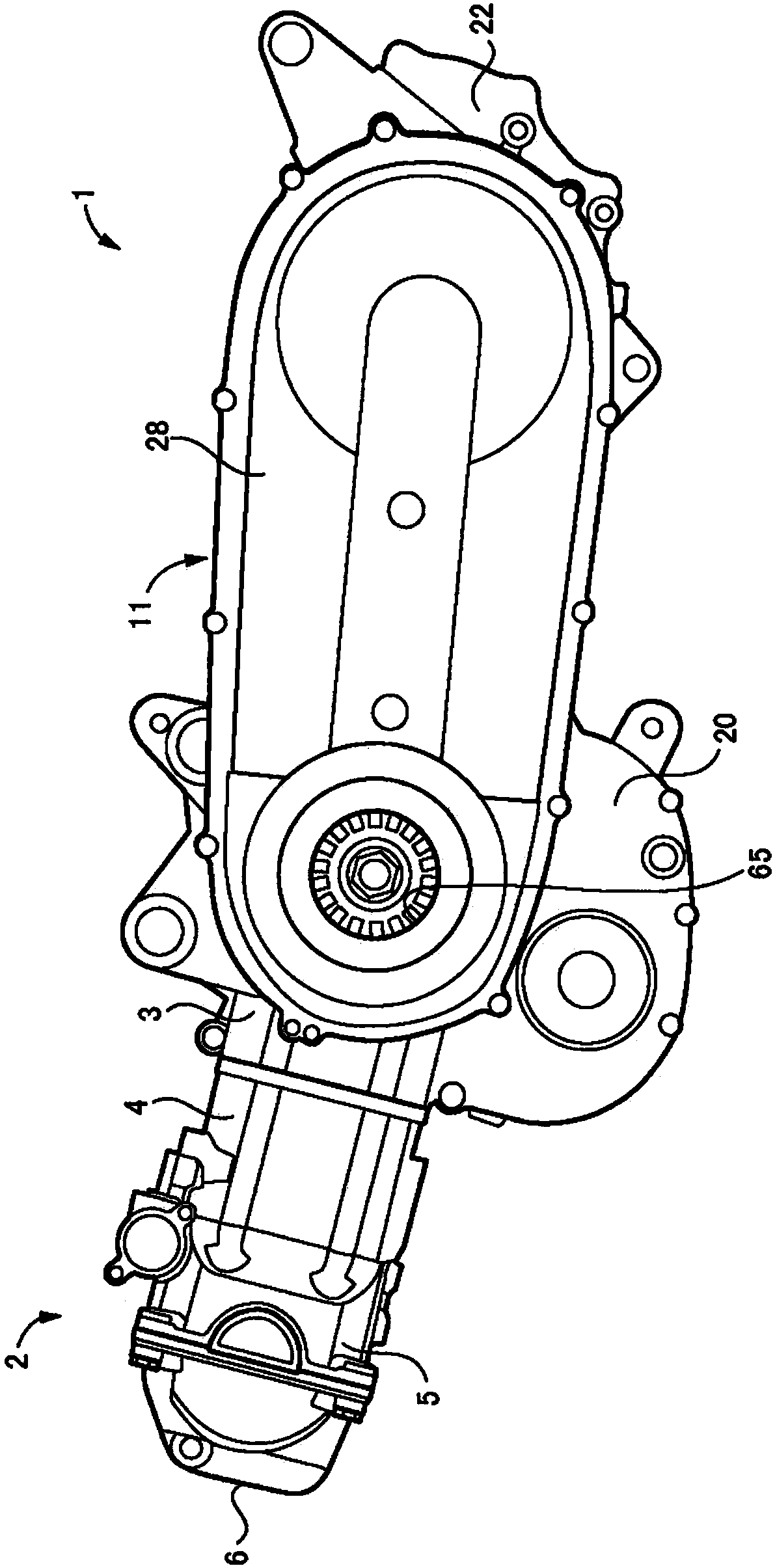

[0089] Figure 1 to Figure 7 An engine unit including a cooling structure such as a belt-type continuously variable transmission according to an embodiment of the present invention is shown. which is, figure 1 means the engine unit as a whole, figure 2 express figure 1 The left side of the engine unit 1 in. image 3 expressed in figure 2 In the engine unit 1 in the state where the side cover 29 and the like have been removed, Figure 4 Furthermore, the state which removed the transmission case cover 28 is shown. Figure 5 express figure 1 on the right side of the engine unit 1 in the Figure 6 expressed in Figure 5 The state in which the gear box case 41 is removed from the engine unit 1 in FIG. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com