Blowout preventer side doors and blowout preventer with left and right interchangeable side doors

A blowout preventer, left and right side technology, applied in wellbore/well components, earthwork drilling, sealing/packing, etc., can solve the problems of increased design cycle, more inventory, and more inspection items, and reduce production costs. , The effect of reducing production cycle and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

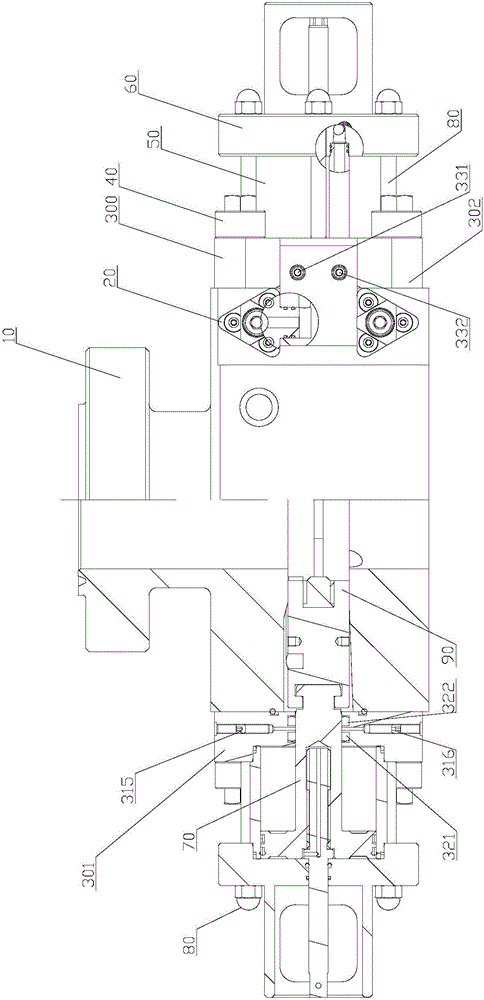

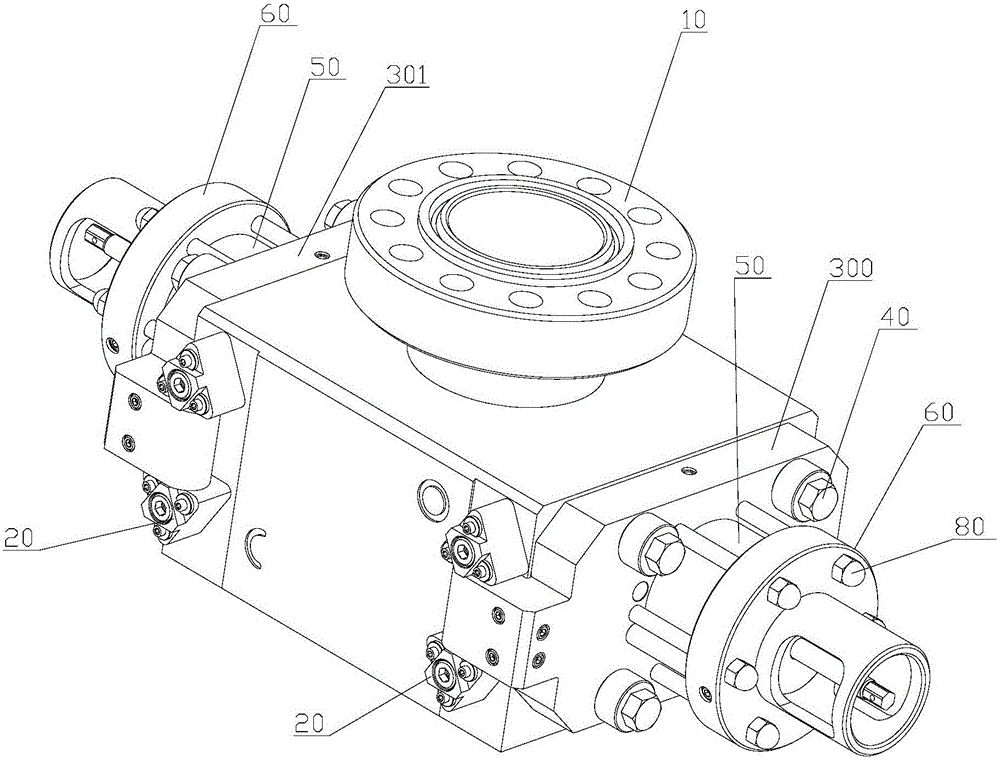

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

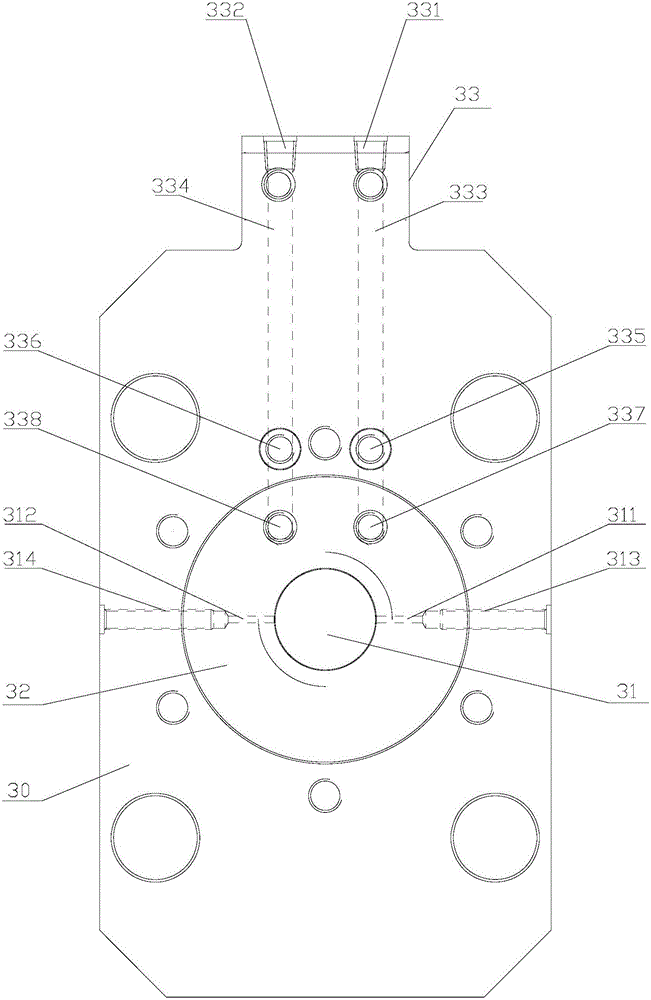

[0023] see figure 1 , a side door of the blowout preventer of the present embodiment includes a side door body 30, and the side door body 30 is provided with a side door inner hole 31 and a liquid cylinder groove 32. The upper end of the side door body 30 has a hinge connection part 33, and the hinge connection parts 33 are respectively There are a first oil hole 333 and a second oil hole 334 extending from top to bottom to the cylinder groove 32. The cylinder groove 32 is provided with a first inner oil hole 337 communicating with the first oil hole 333. 32 is also provided with a first outer oil hole 335 communicating with the first oil hole 333, and a second inner oil hole 338 communicating with the second oil hole 334 is provided on the liquid cylinder groove 32. A second outer oil hole 336 communicating with the second oil hole 334 is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com