Sliding windows and how they work

A technology for sliding windows and inner windows, applied in door/window accessories, sealing devices, buildings, etc., which can solve the problem of moving the movable window to any position on the guide rail, limiting the movable range of the movable window, and changing the gap between the chute and the lock pin. Large and other problems, to achieve the effect of reducing occupancy, prolonging life, and saving effort during opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

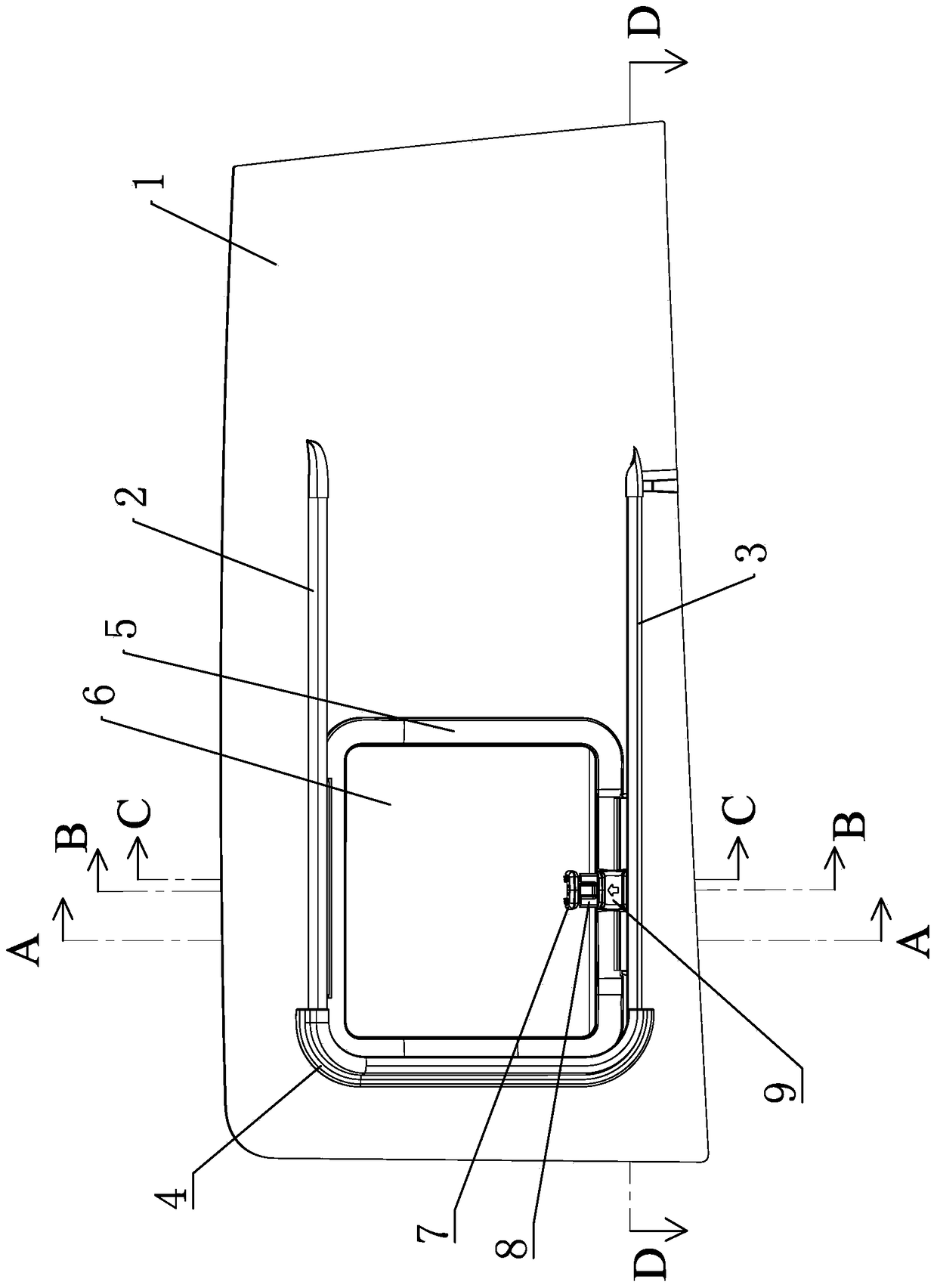

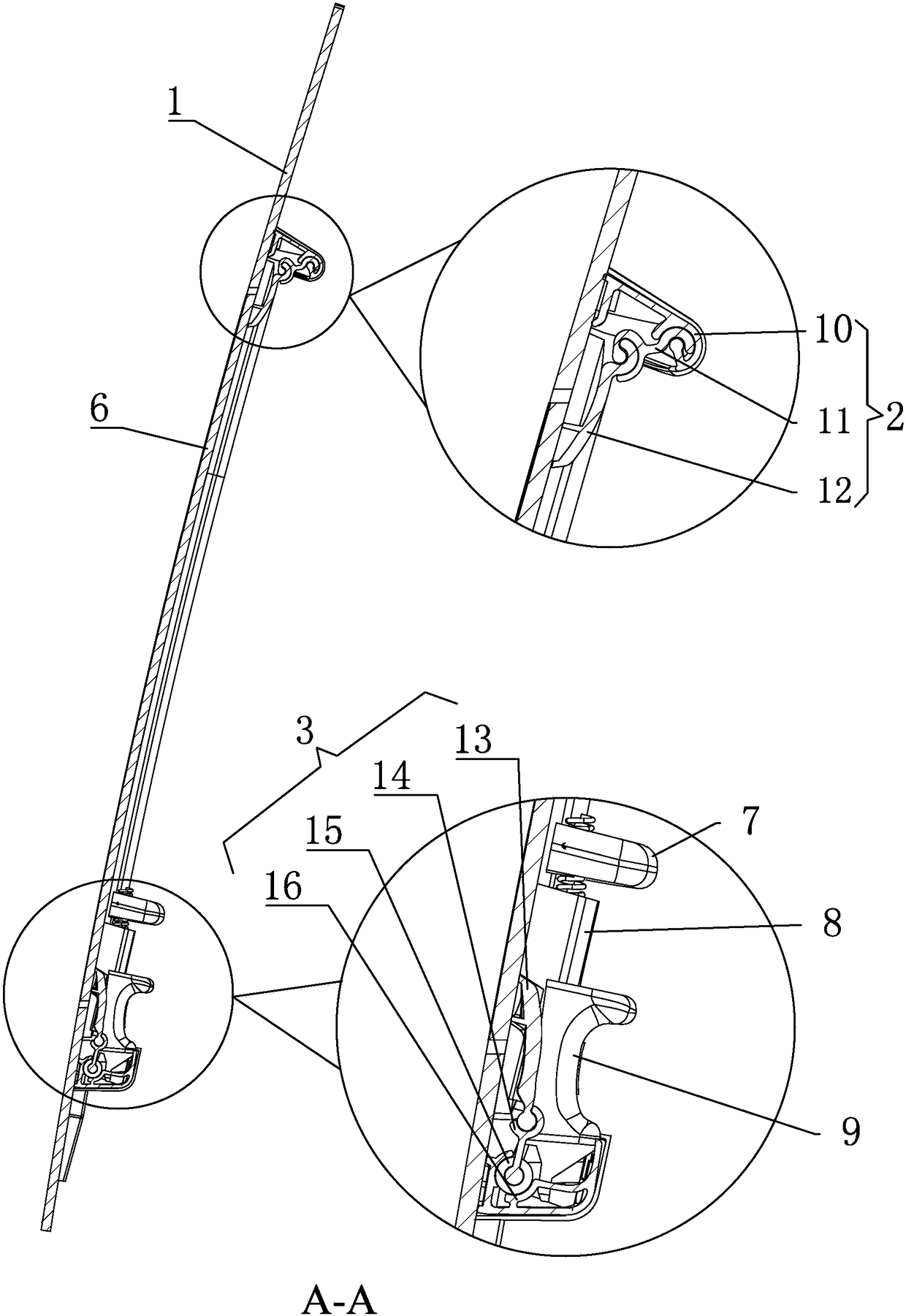

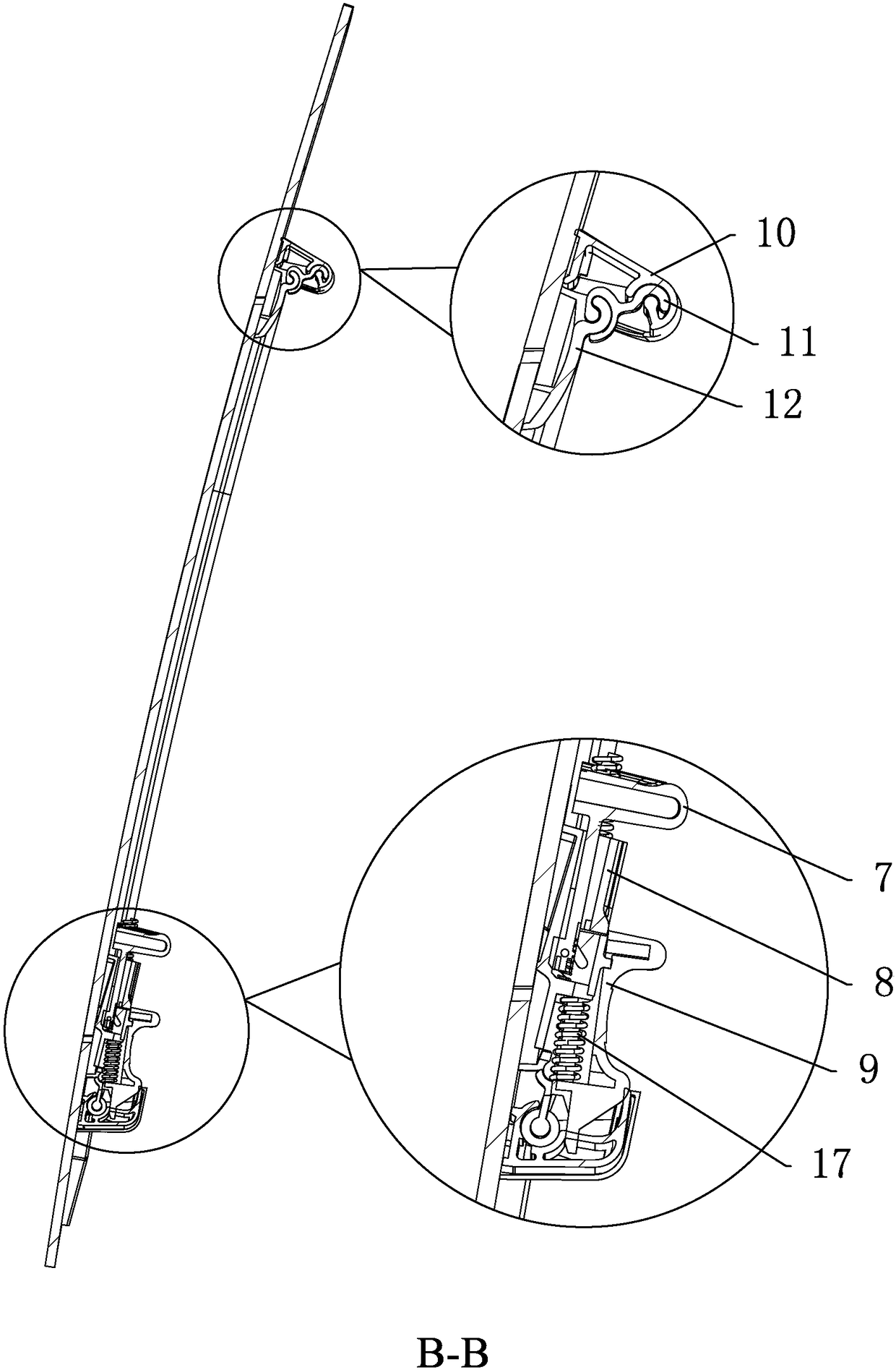

[0044] The sliding window includes: fixed window 1, upper sliding mechanism 2, lower sliding mechanism 3, window cover 4, inner window frame 5, inner window 6, upper handle 7, connecting block 8, lower handle 9, upper guide rail 10, upper connecting bar 11, upper bracket 12, lower bracket 13, lower connecting bar 14, casing 15, lower guide rail 16, spring 17, window hole 18.

[0045] Such as figure 1 and Figure 15As shown, the fixed window 1 is a glass structure, and the inner surface of the fixed window 1 is provided with a pair of horizontal sliding mechanisms, which include an upper sliding mechanism 2 and a lower sliding mechanism 3, and a fixed window 1 located between the upper and lower sliding mechanisms is provided. There is a window hole 18, the inner window 6 matches the shape of the window hole 18, the inner window 6 is made of glass, the outer circumference of the inner window 6 is provided with an inner window frame 5, and a seal is provided between the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com