Panel control system of purifying water tank

A control system and panel technology, applied in control/manipulation systems, lighting water/sewage treatment, etc., can solve the problems of simple functions, unclean cleaning, occupying kitchen space, etc., to reduce the breeding of bacteria, save washing time, strengthen Effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

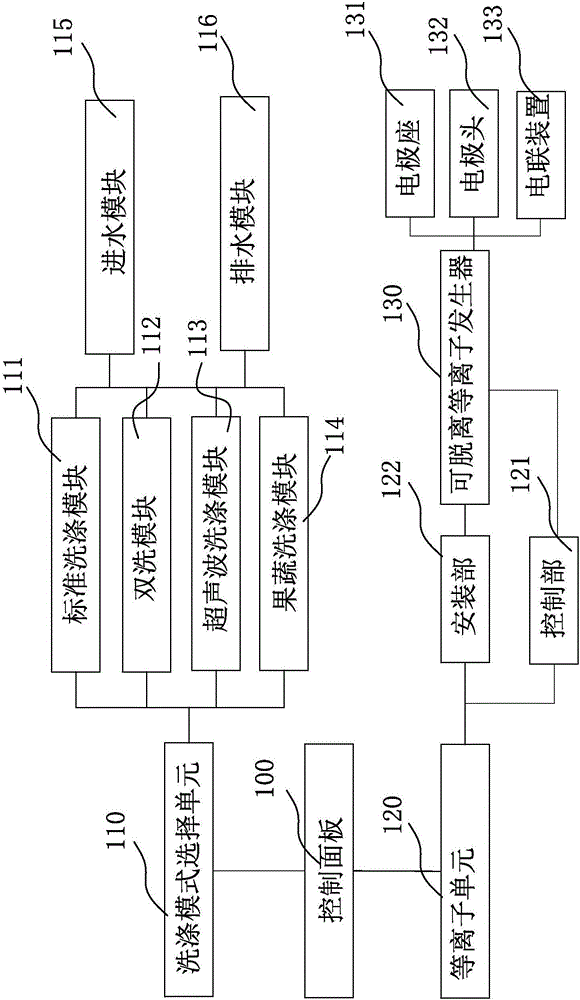

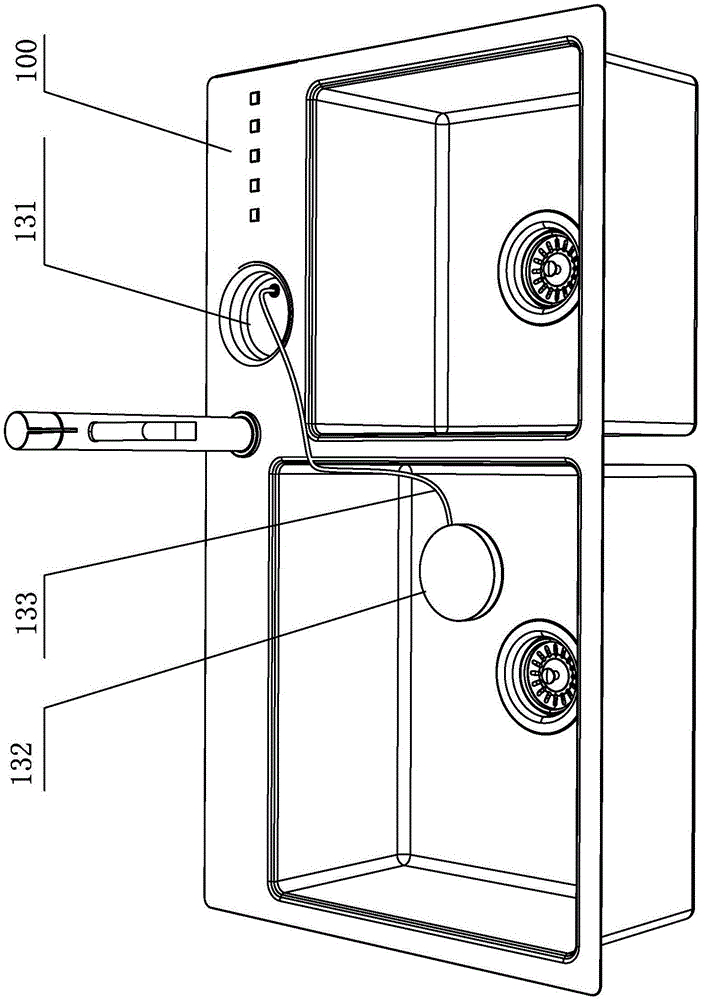

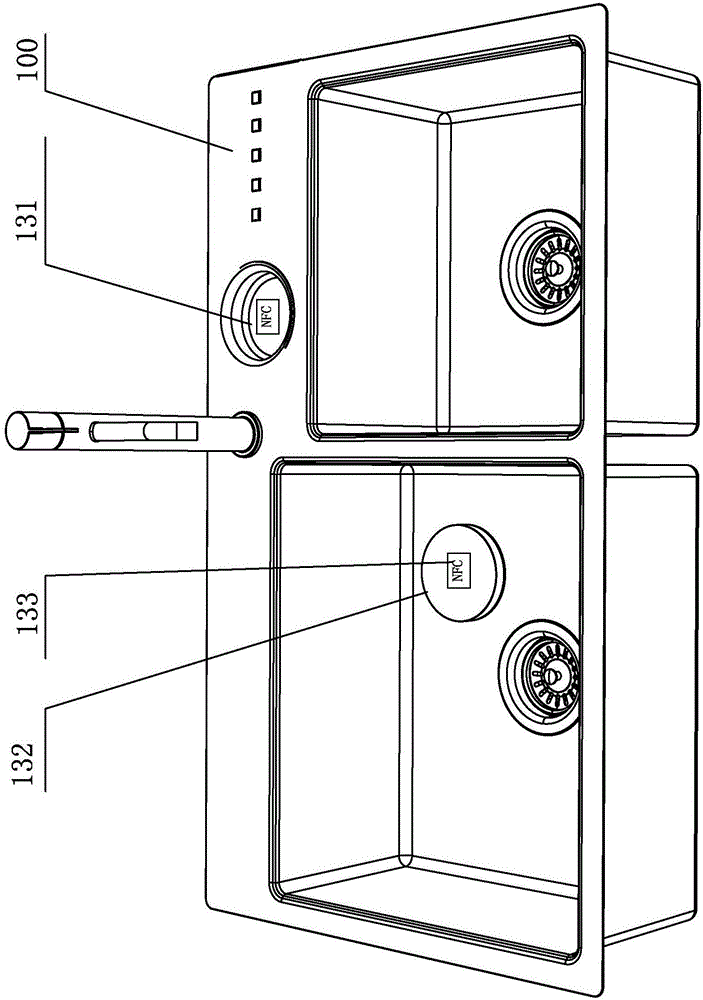

[0049] Such as figure 1 and figure 2 As shown, a panel control system for a purified water tank includes a washing module selection unit 110 and a plasma control unit 120, the washing module selection unit 110 and the plasma unit 120 are installed on the control panel 100,

[0050] The washing module selection unit 110 is provided with a standard washing module 111, a double washing module 112, an ultrasonic washing module 113 and a fruit and vegetable washing module 114; There is an ultrasonic cleaning module 113;

[0051] The plasma unit 120 includes a control part 121 detachable from the plasma generator 130 and a mounting part 122 , and the mounting part 122 is provided with an electrode slot 131 for storing and ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com