Sensitive structure and accelerometer with super-high acceleration displacement sensitivity and manufacturing method

A sensitive structure and acceleration technology, which is applied in the direction of measuring acceleration, velocity/acceleration/shock measurement, and microstructure devices composed of deformable elements, can solve the problem of not being able to obtain ultra-high acceleration measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

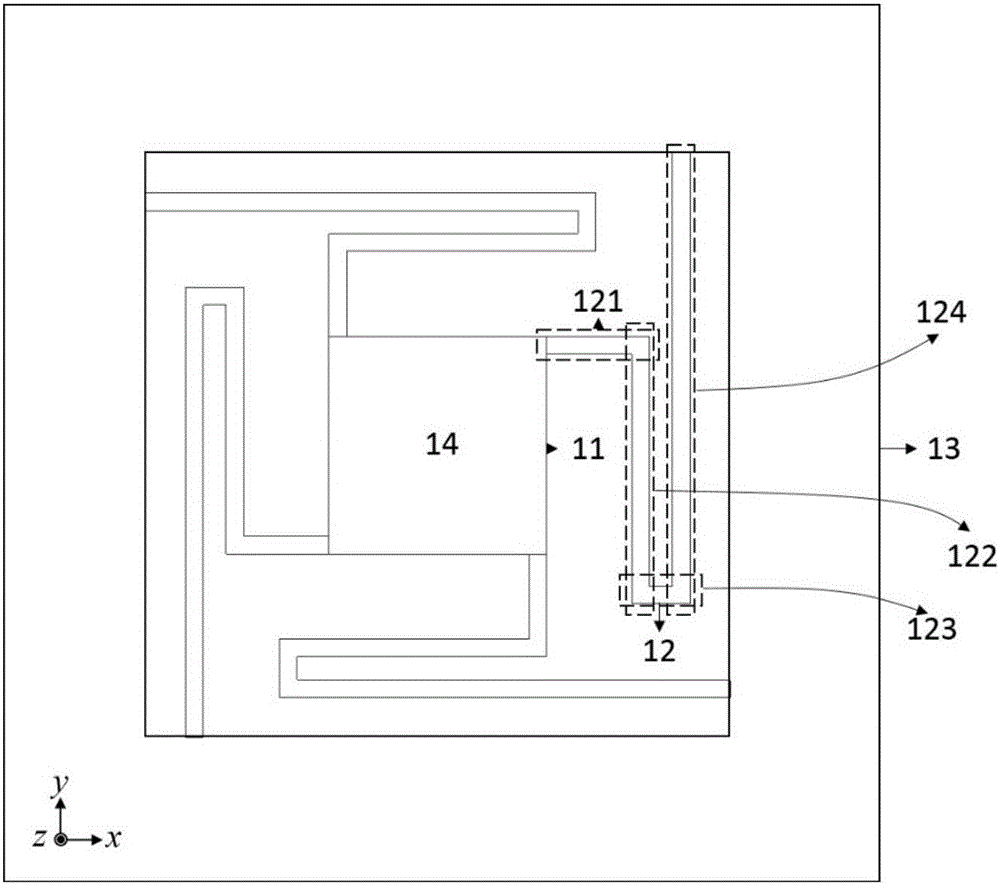

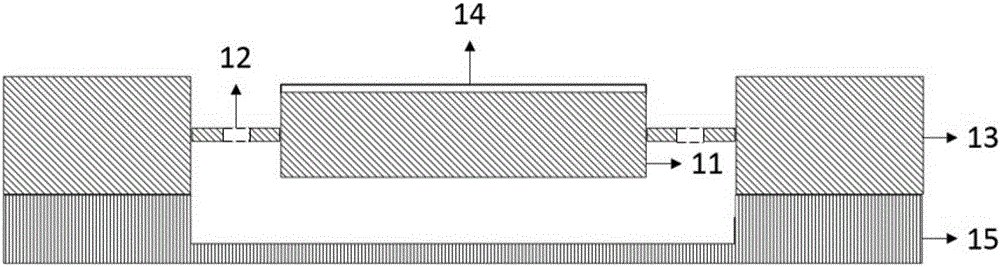

[0067] The implementation of the present invention will be described in detail below with reference to the drawings and specific examples, and those skilled in the art can understand other advantages and effects of the present invention from this description. It should be noted that the diagrams provided in this embodiment are only schematic diagrams illustrating the basic idea of the present invention, and the relevant components in the schematic diagrams are not necessarily drawn according to the number, shape and size of components in actual implementation.

[0068] Embodiments of the present invention and its implementation process are as follows:

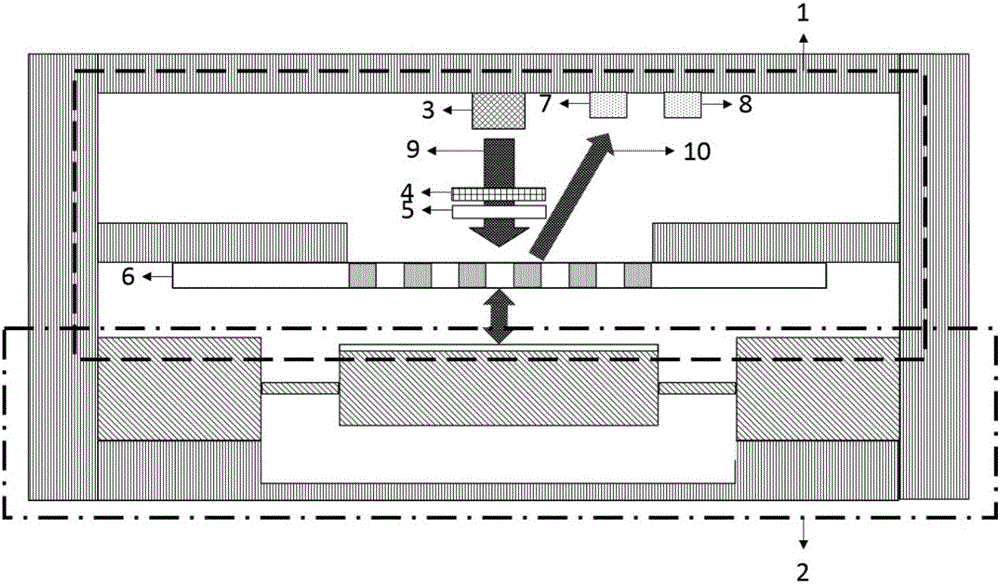

[0069] Such as figure 1As shown, the micromechanical sensitive structure 2 of the present invention is a passive device, which acts as an acceleration sensitive module in an optical microaccelerometer; the micromechanical sensitive structure 2 includes a sensitive mass 11, a high reflection film 14 plated on the sensitive ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com