Differential aircraft carrier catapult

A catapult and differential technology, applied in the direction of launch/drag transmission, etc., can solve the problems of high consumption of fresh water, low efficiency, high energy consumption, etc., and achieve the effect of simple structure, easy manufacture, and increased reserves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and examples.

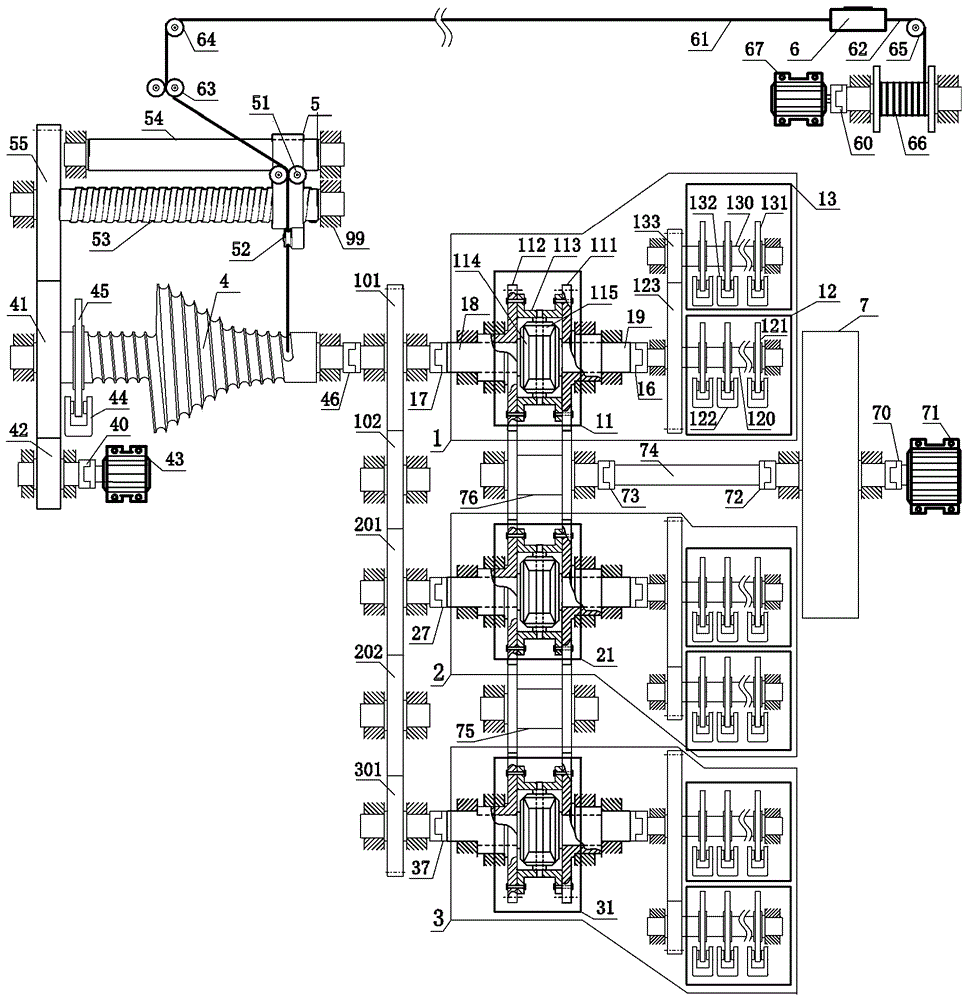

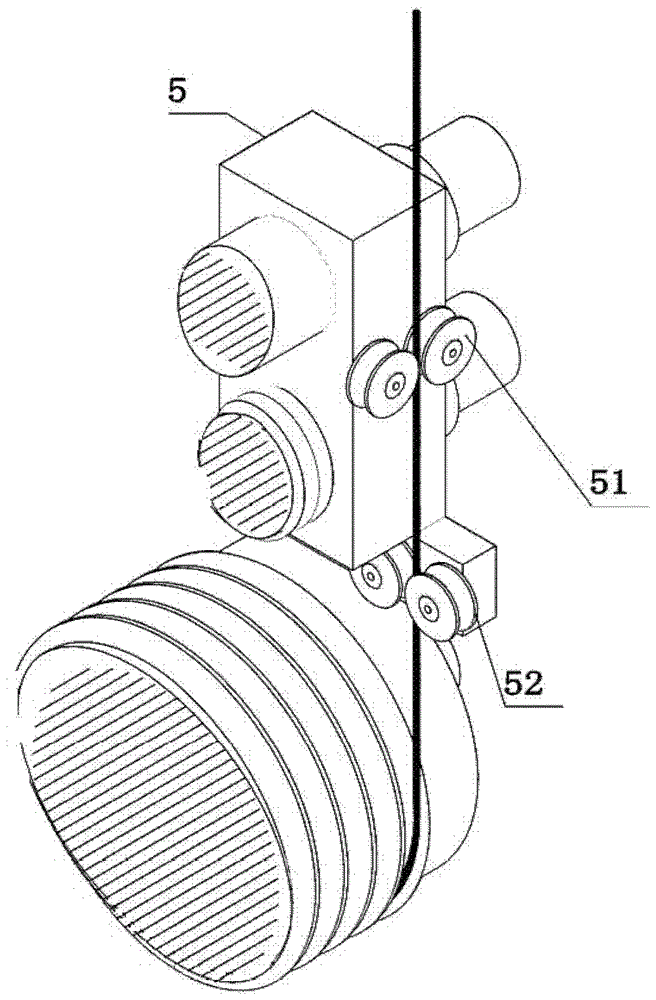

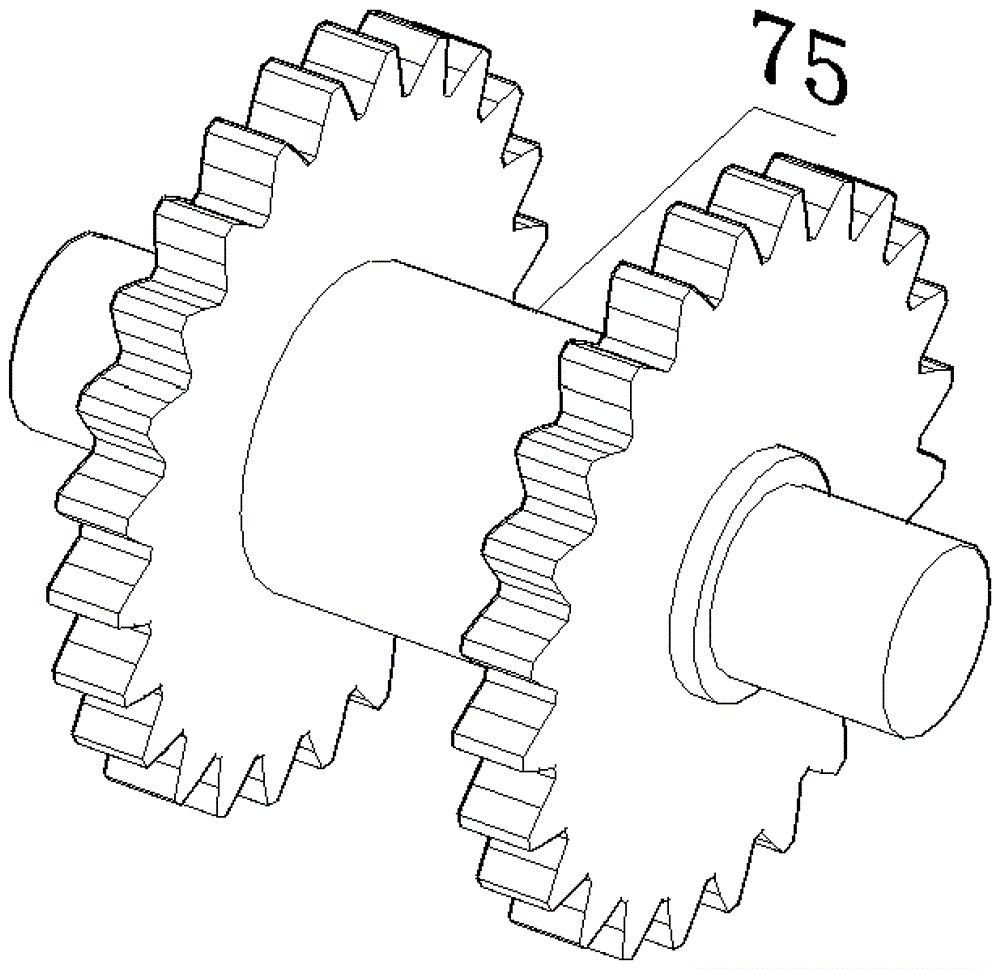

[0037] A differential aircraft carrier catapult, comprising a first differential group 1, a first transmission coupling 17, a first transmission gear 101, a rope winding roller coupling 46, a rope winding roller 4, a power motor 71, a power coupling Shaft 70, energy storage flywheel 7, flywheel coupling 72, power transmission shaft 74, double gear coupling 73, power double gear 76, rope winding roller gear 41, parking brake disc 45, parking brake caliper 44, lead screw 53. Lead screw gear 55, traveling shaft 54, limit assembly 5, ejection wire rope 61, positioning pulley block 63, first guide pulley 64, second guide pulley 65, ejection shuttle 6, tension wire rope 62, tension winch 66 , tension coupling 60, tension motor 67, DC servo motor 43, servo coupling 40, servo gear 42; It is characterized in that it also includes the vertical limit pulley block 52 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap