A substrate fine-tuning device installed with a forced feeder

A fine-tuning device and feeder technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of low work efficiency, time-consuming and laborious, and inaccurate adjustment of the gap between the bottom surface of the forced feeder and the working surface of the turntable, etc., to achieve Improve production efficiency, exchange and clean up the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

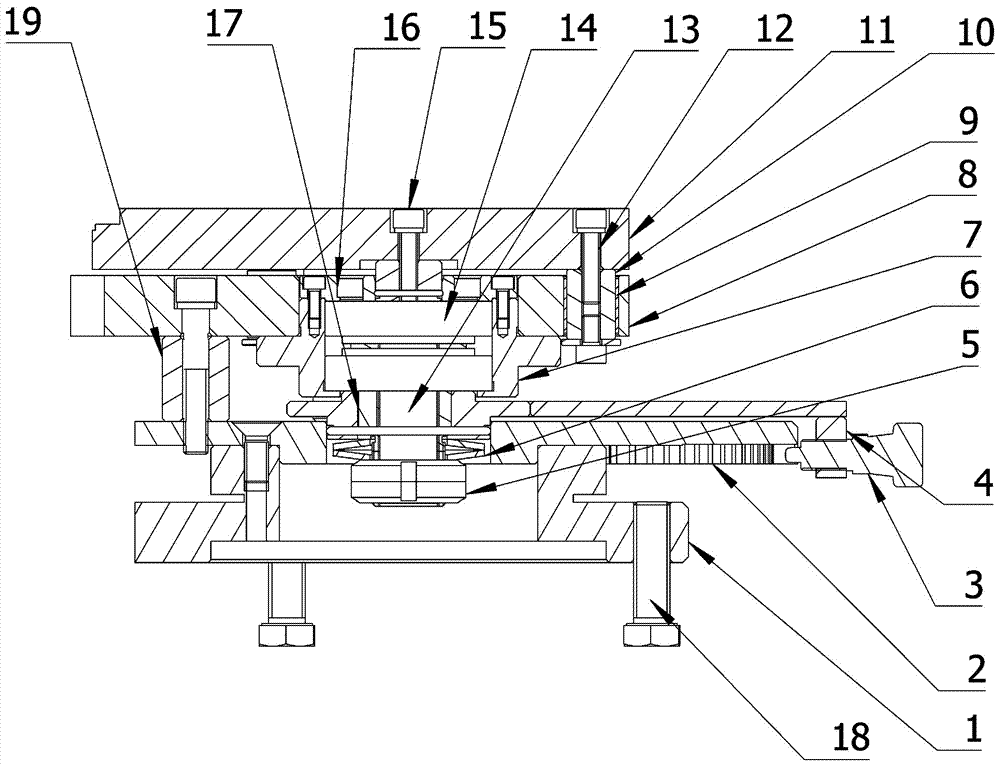

[0008] The fine-tuning device for the substrate installed with the forced feeder of the present invention will be further described through the following drawings and examples.

[0009] like figure 1 As shown: the substrate fine-tuning device for installing a forced feeder of the present invention includes: a base 1, an indexing gear plate 2, a locking and positioning handle 3, an adjustment handle seat 4, a round nut 5, a disc spring 6, a bearing seat 7, and a bottom plate 8. Oil-impregnated bearing sleeve 9, guide column 10, mounting base plate 11, screw 12, lifting screw 13, bearing 14, connecting screw 15, gland 16, key 17, connecting bolt 18, column cover 19, of which the indexing gear plate 2 Fixed above the base 1, the bearing 14 and the lifting screw 13 are loaded into the bearing seat 7 and then loaded into the gland 16, the adjustment handle seat 4 is set on the outside of the lifting screw 13, connected with the key 17, and then the disc spring 6, the round The nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com