Die assembly mechanism for injection molding machine

A technology of mold clamping mechanism and injection molding machine, which is applied in the field of mold clamping mechanism of injection molding machine, and can solve the problems of low mold clamping speed, low efficiency, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

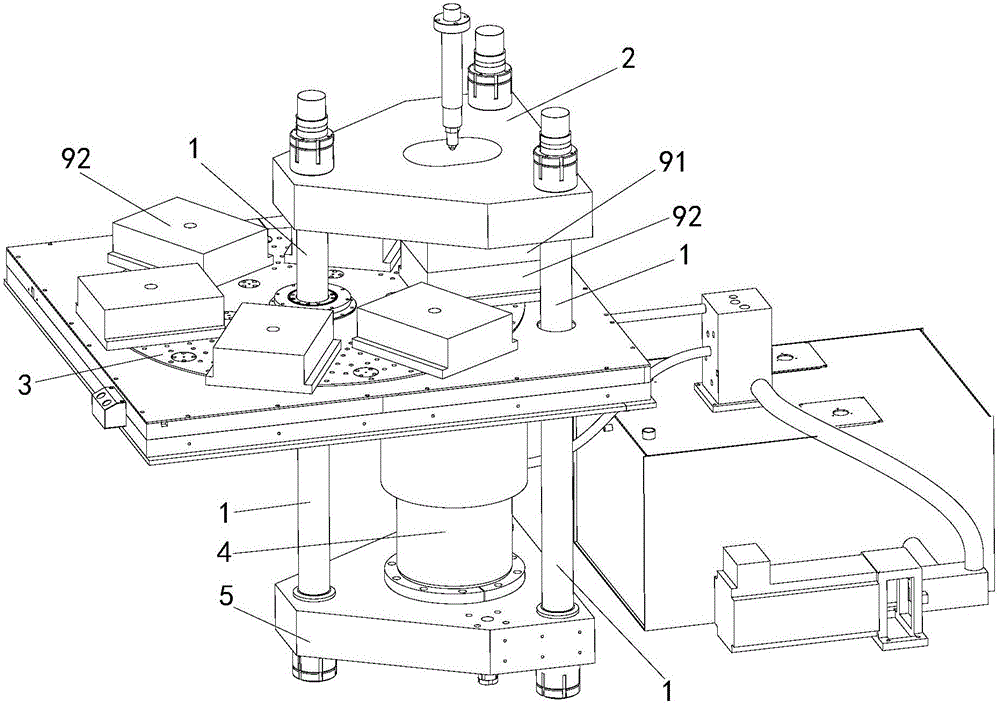

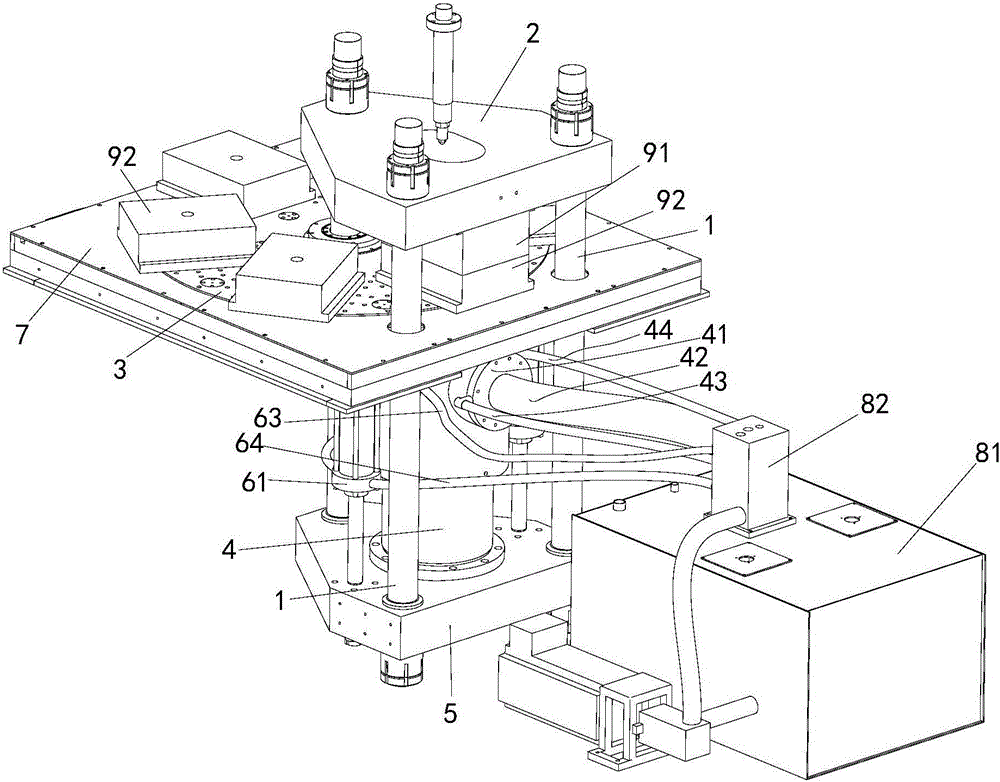

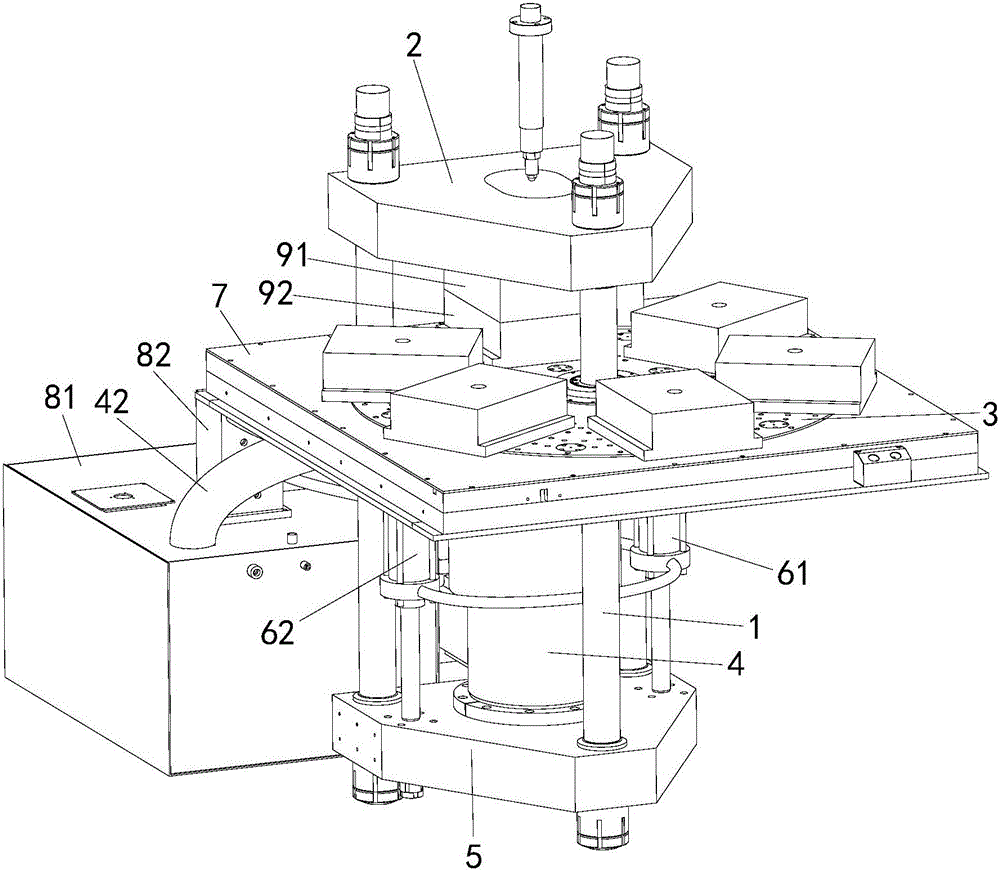

[0025] like Figure 2 to Figure 4 As shown, in this embodiment, the clamping mechanism for the injection molding machine includes: a first fixing plate 2 for fixing the first half mold 91, a second fixing plate 3 for fixing the second half mold 92, an oil cylinder Combination, Corinthian column 1 and the bearing plate 5 carrying the combined force of the oil cylinder, the oil cylinder combination is used to drive the first fixed plate 2 to move down or upward along the length direction of the Corinthian column 1, to realize the connection with the second fixed plate 3 toward or against each other, and then realize the mold closing or mold opening of the first half mold 91 and the second half mold 92. Wherein, the second fixed plate 3 is a rotatable disc, which can be rotated on the frame 7, thereby realizing the replacement of the second half-mold 92 . The oil cylinder combination includes the active oil cylinder 61 / 62 and the slave oil cylinder 4 with the same movement traje...

Embodiment 2

[0033] In this embodiment, it is basically the same as Embodiment 1, except that the slave cylinder 4 includes a hydraulic oil chamber, which includes a pressure oil pipe 44 that communicates with or is disconnected from the high-pressure hydraulic oil pipeline, and is connected with the normal hydraulic oil pipeline. The pressure hydraulic oil is connected or disconnected from the normal pressure oil pipe 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com