Modular high-redundancy multi-degree-of-freedom flexible mechanical arm system

A technology of flexible manipulators and manipulators, applied in the direction of manipulators, program-controlled manipulators, claw arms, etc., can solve the problems of low load, difficult work, impossible work with force load, etc., and achieve high precision and strong movement ability , the effect of high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

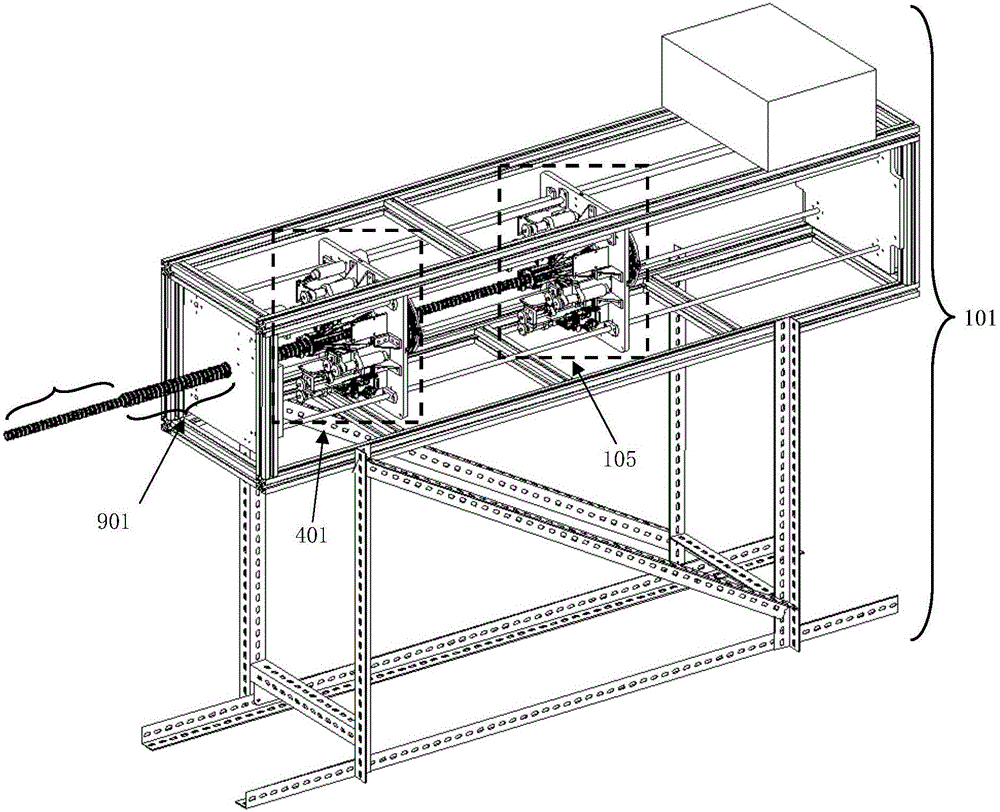

[0042] A flexible manipulator system with high redundancy and multiple degrees of freedom. The flexible manipulator system consists of two manipulator modules with similar structures. The two-section robotic arm modules are nested and combined, and can perform relative movement. The single-section manipulator module has 3 degrees of freedom, namely 2 degrees of freedom for bending and 1 degree of freedom for feeding. So this flexible robotic arm system will have 6 degrees of freedom. When the flexible manipulator system is working, each manipulator module is stretched out step by step, and bending motion can be realized during the stretching process. The flexible manipulator system integrates different end effectors to complete different tasks in complex environments.

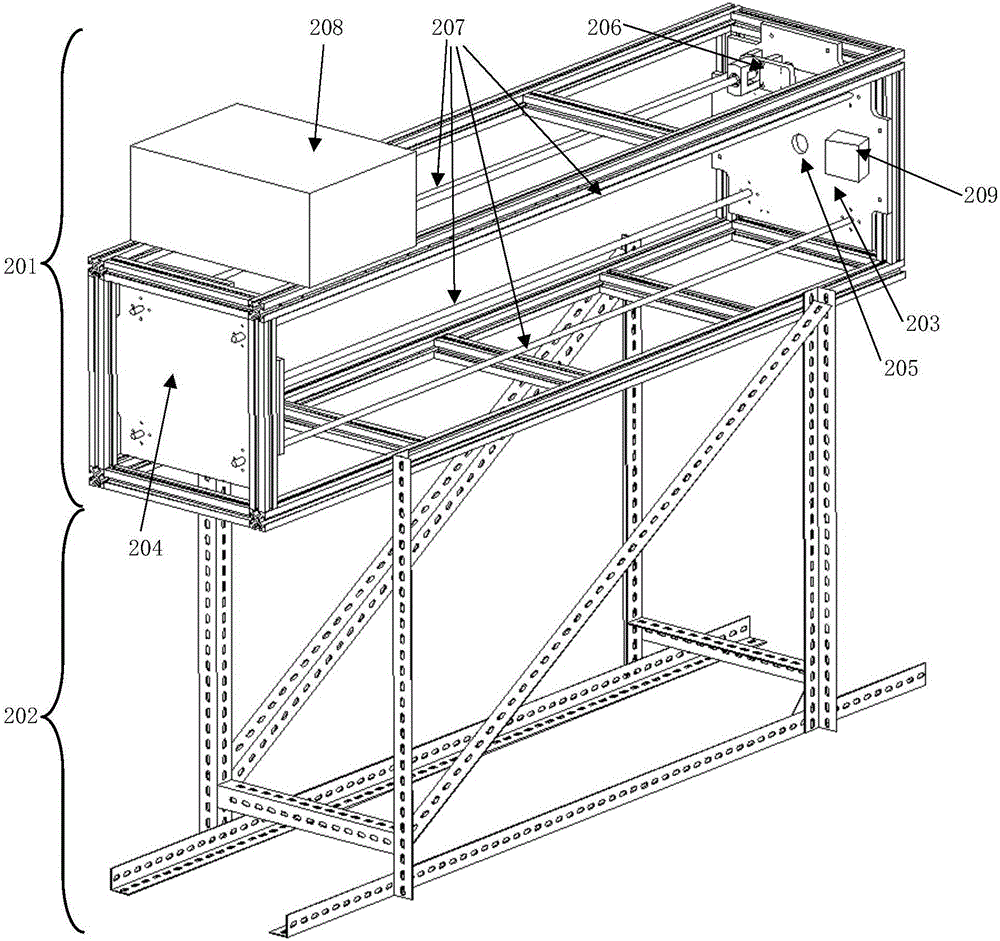

[0043] Such as figure 1 As shown, the perspective view of the flexible manipulator system includes a frame 101 and two manipulator modules. The first section of the manipulator module includes a functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com