Fluid vibration exciter

A vibrator, fluid technology, applied in the direction of the use of vibration fluid, etc., can solve the problems of short service life, discontinuous generation of excitation force, applicability constraints, etc., to solve the problem of insufficient excitation force and increase the energy conversion rate , Reduce the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

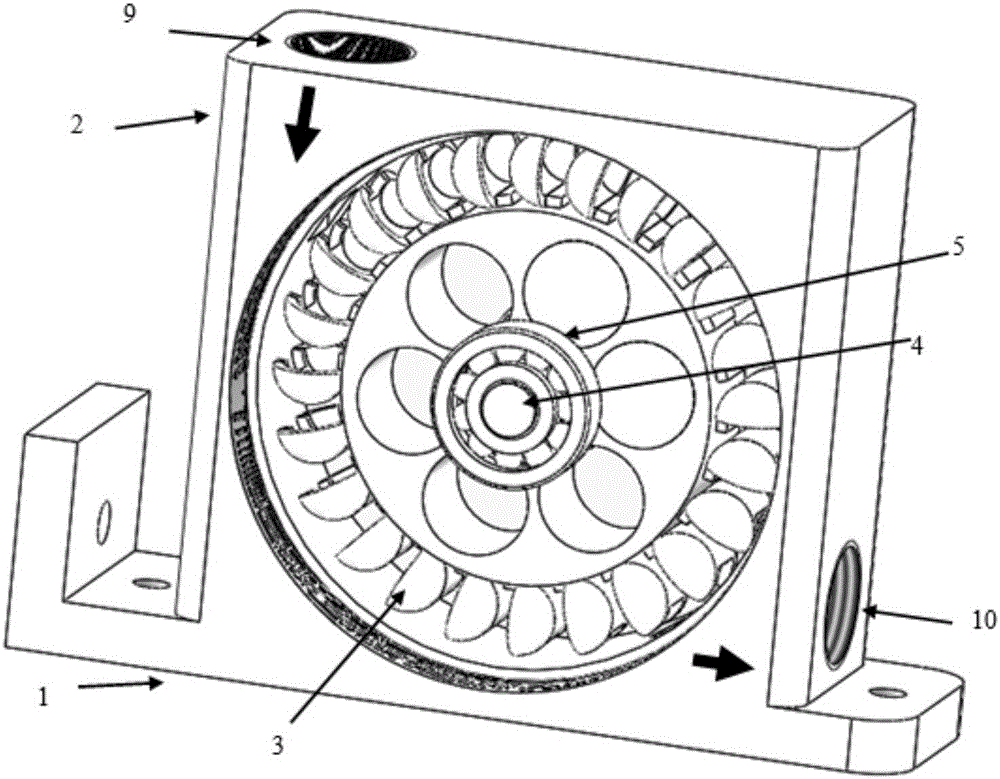

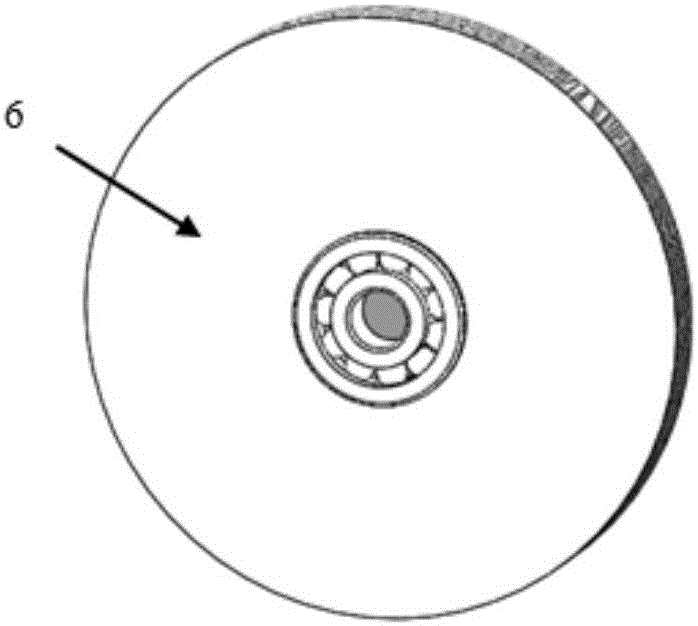

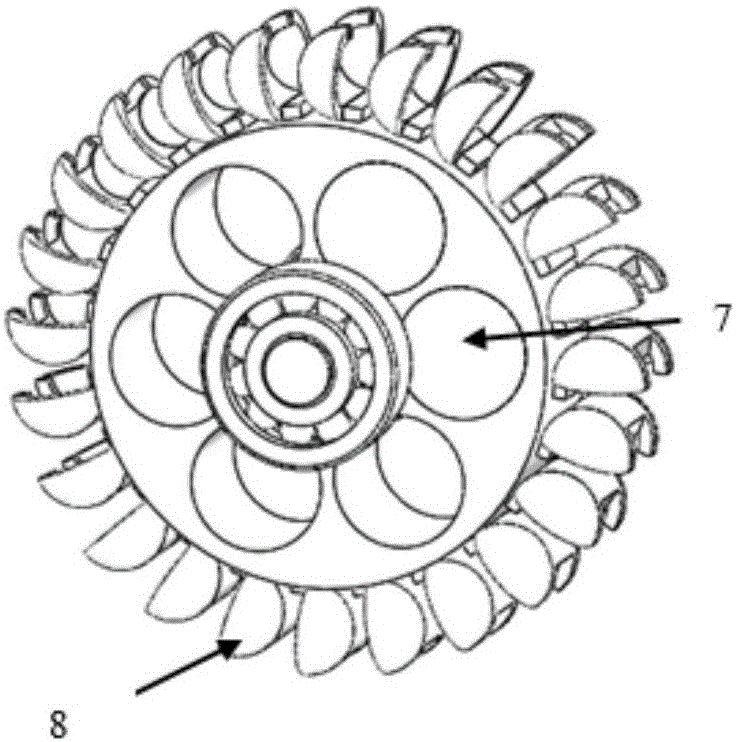

[0032] Such as Figure 1-3 As shown, for a water pressure of 1Mpa, this embodiment provides a fluid exciter with strong exciting force, convenient and durable, consisting of a base 1, a housing 2, an exciting element 3, an optical axis 4, a waterproof bearing 5, Cavity cover plate 6, eccentric vibrator 7, turbine blade 8, water inlet 9 and water outlet 10, wherein:

[0033] The base 1 and the housing 2 arranged on the base 1 form an integral structure, which is rigid, dense and high in strength, and can be fixed by screws passing through the horizontal and vertical plate holes on both sides of the base;

[0034] The middle part of the housing 2 is provided with a cylindrical cavity, and the upper part of the housing 2 is provided with a water inlet 9 along the tangential direction; the water outlet 10 is provided on the center line of the bottom of the right side plate of the housing 2;

[0035] The excitation element 3 is composed of an eccentric vibrator 7 and a turbine bla...

Embodiment 2

[0050] Such as Figure 1-3 As shown, for a water pressure of 1Mpa, this embodiment provides a fluid exciter with strong exciting force, convenient and durable, consisting of a base 1, a housing 2, an exciting element 3, an optical axis 4, a waterproof bearing 5, The cavity cover plate 6, the eccentric vibrator 7, the turbine blade 8, the water inlet 9 and the water outlet 10 are composed, and the assembly method of each component is the same as that described in the first embodiment.

[0051] In this embodiment, the size of the base 1 is: 80*45*10mm, and it is connected with the housing 2 to form a whole.

[0052] In this embodiment, the size of the housing 2 is: length*width*height=45*45*45mm; the upper part of the water inlet 9 on the top of the housing 2 is an M20 threaded hole, and 4 water supply pipes are externally connected through quick connectors; The size of the rectangular opening at the lower part of the housing 2 is length*width=12*3mm; the water outlet 10 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com