Orthodontic bracket system and tooth orthodontic method

An orthodontic bracket and bracket technology, which is applied in the field of orthodontics and traction/locking elements, can solve the problems of small operation space, small force on the traction hook, and shortened retention time, so as to achieve convenient installation and disassembly. , The effect of reducing discomfort and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

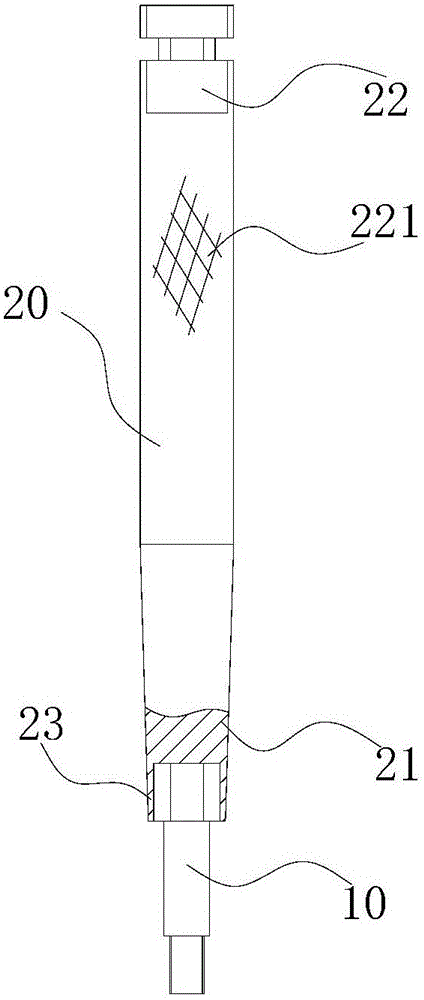

[0063] Such as Figure 1 to Figure 9 As shown, the orthodontic bracket system includes a bracket body 30 and a traction element. The traction element includes a strip-shaped nail body 10 and a handle 20. The front end of the nail body 10 is the first fixed end 11, and the rear end is the first fixed end. The screwing end 12 and the first fixed end 11 are provided with a connecting external thread 111 , and a first force application surface 121 is provided at least at the end of the first screwing end 12 . A main groove 31 is provided on the bracket body 30 , and a reserved hole 32 is provided on the side of the bracket body 30 , the reserved hole 32 is a through hole, and its inner end is connected to the main groove 31 . The inner diameter of the reserved hole 32 is 0.2 to 1.6 millimeters (wherein, preferably 0.5 millimeters to 1.2 millimeters), and the inner wall of the reserved hole 32 is provided with a connecting internal thread; the cross-sectional area of the nail bod...

Embodiment 2

[0088] Such as Figure 10 , Figure 11 As shown, in this embodiment, when the nail body 10 is in the maximum tightened state, the front end of the pressing section 122 protrudes from the main groove 31 .

[0089] Since the size of the archwire 40 will be smaller than the size of the main groove 31 (otherwise the archwire 40 cannot be placed in the main groove 31), the archwire 40 will deviate in the main groove 31, thereby affecting orthodontics In this embodiment, the size of the nail body 10 is slightly longer than that of Embodiment 1. At this time, the nail body 10 passes through the reserved hole 32 and presses against the arch wire 40, and the arch wire 40 is pressed through the nail body 10. 40 is locked. Compared with the first embodiment, this embodiment can reduce the deviation of the arch wire 40 and improve the accuracy of the arch wire 40 for tooth correction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com