Electrical Insulation Structure for Hall Thruster Gas Supply Line

A technology of Hall thruster and air supply pipeline, applied in thrust reverser, using plasma, machine/engine, etc., can solve problems such as insulation failure, and achieve the effect of good insulation performance, high reliability and improved insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

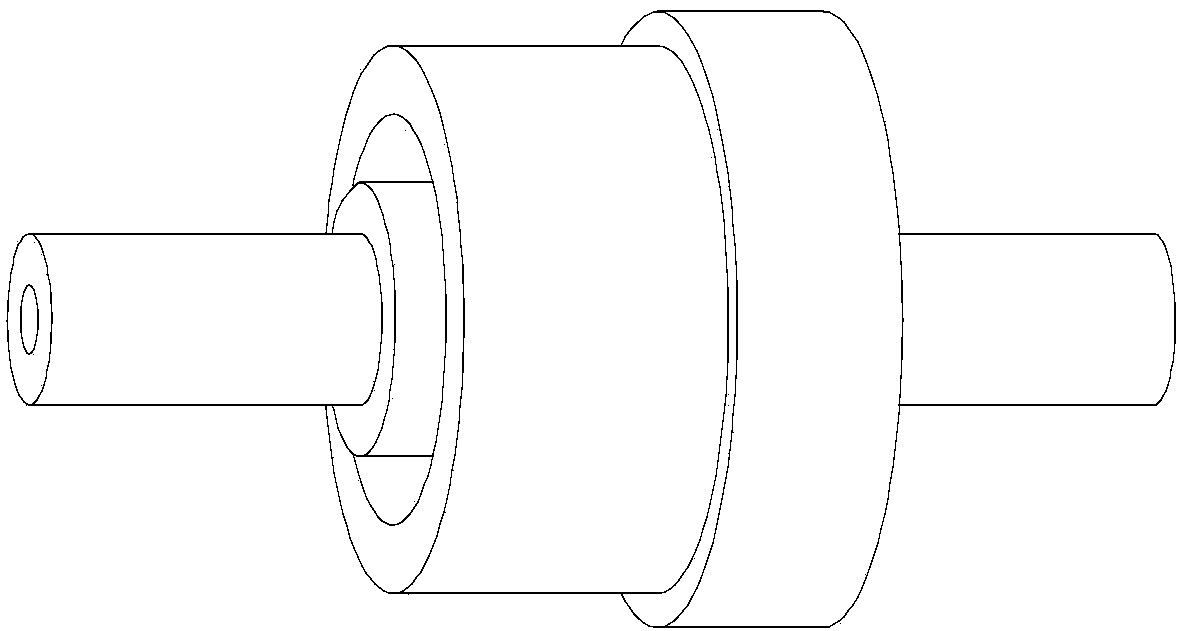

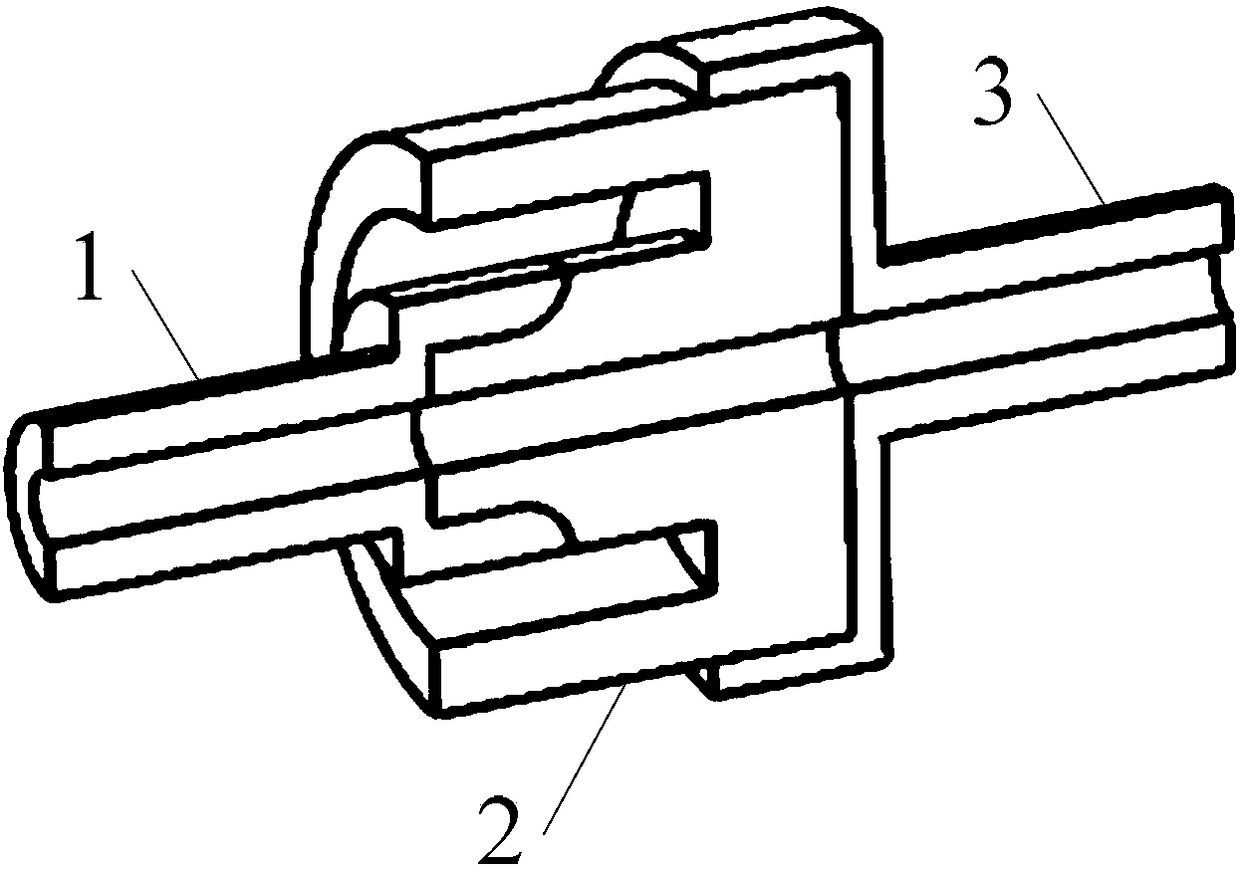

[0018] Specific implementation mode one: refer to Figure 1 to Figure 4 Describe this embodiment in detail, the electrical insulation structure used for the gas supply pipeline of the Hall thruster described in this embodiment, it includes a gas distributor pipeline 1, a ceramic insulator 2 and a metal port 3 of the storage and supply system,

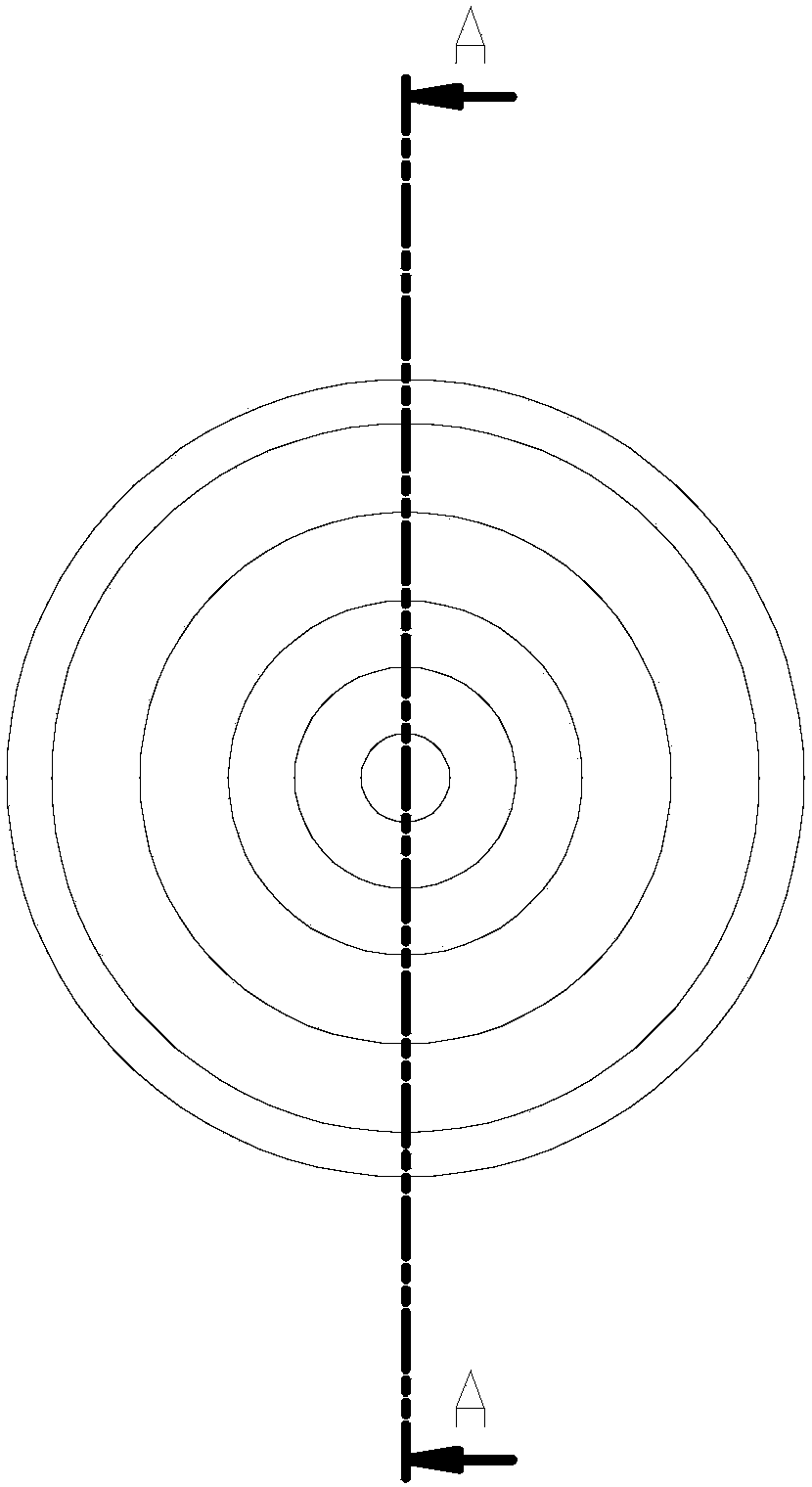

[0019] The cross-section of the ceramic insulator 2 has a "mountain"-shaped structure, and the outer surface of the ceramic insulator 2 is a cylindrical structure, and the middle end of the ceramic insulator 2 is a convex groove structure.

[0020] The metal port 3 of the storage and supply system is wrapped on the bottom of the ceramic insulator 2, the groove structure of the gas distributor pipeline 1 is connected with the convex groove structure of the ceramic insulator 2, and the ceramic insulator 2 wraps the gas distributor pipeline 1,

[0021] The inner cavity of the gas distributor pipeline 1, the ceramic insulator 2 and the meta...

specific Embodiment approach 2

[0027] Specific embodiment 2: This embodiment is to further explain the electrical insulation structure used for the gas supply pipeline of the Hall thruster described in the specific embodiment 1. In this embodiment, the metal port 3 of the storage and supply system is connected to the bottom of the ceramic insulator 2 Brazed connections.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment is to further explain the electrical insulation structure used for the gas supply pipeline of the Hall thruster described in Embodiment 1. In this embodiment, the middle end of the ceramic insulator 2 and the gas distributor tube Way 1 solder connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com