New Automatic Body Lifter

A spreader and automatic technology, applied in the field of spreaders, can solve the problems of high cost, inability to open, complex spreader, etc., and achieve the effect of light and practical manufacturing cost, low manufacturing cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

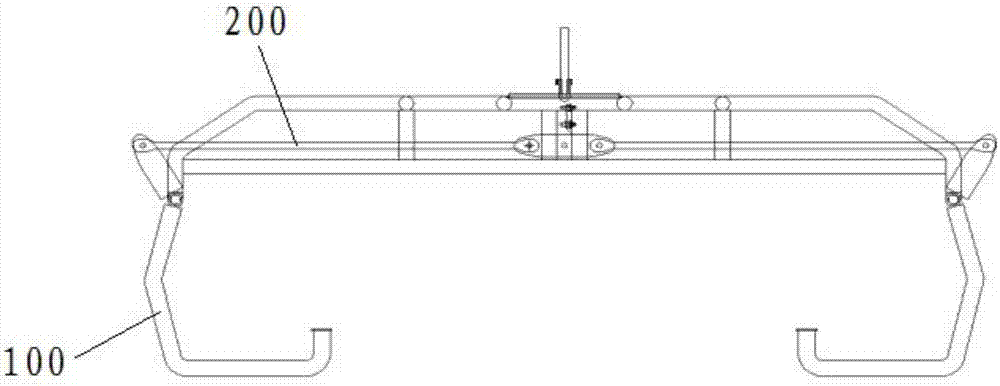

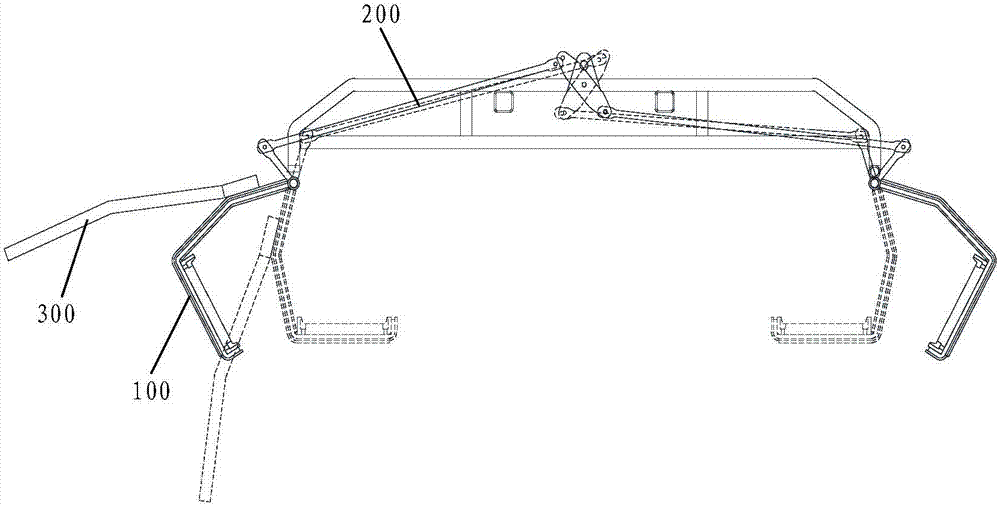

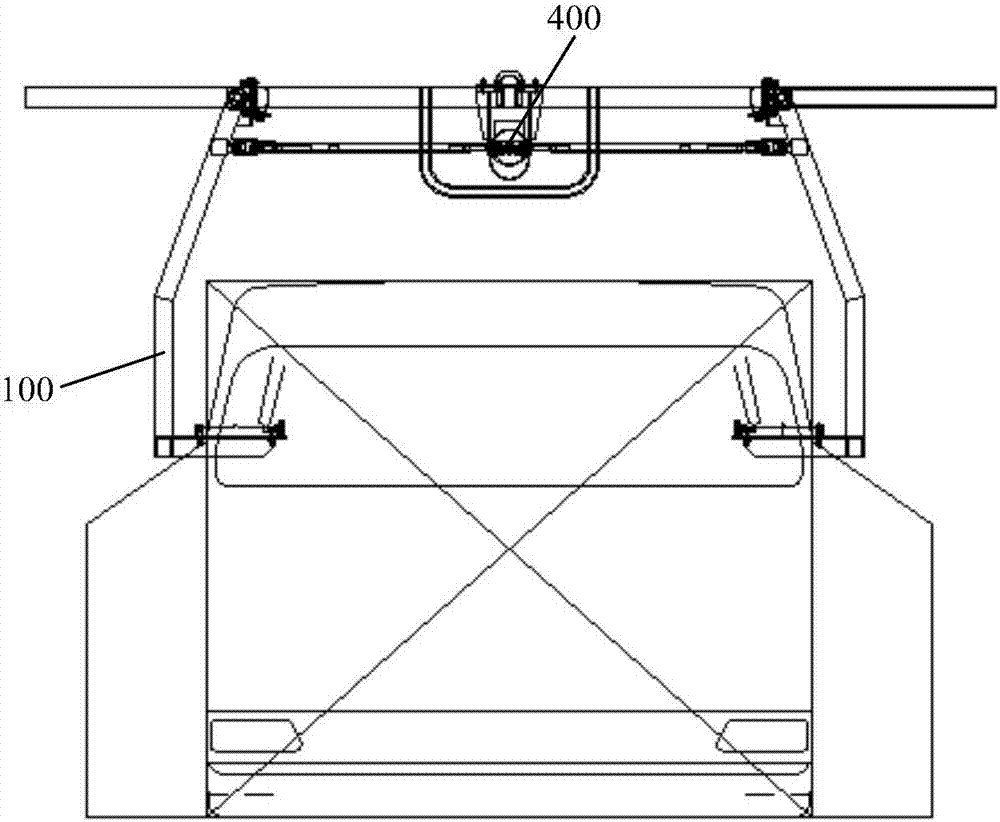

[0028] Embodiments of the invention: as Figure 4-Figure 6 As shown, a new type of automatic vehicle body spreader includes a spreader frame 1 and a first support frame 2 and a second support frame 3 symmetrically installed on both sides of the spreader frame 1, the first support frame 2 and the The second support frame 3 is hingedly connected with the spreader frame 1, the middle position of the spreader frame 1 is provided with a slide rail 4 slidingly connected thereto, the bottom of the slide rail 4 is connected with a pressing plate 5, and the The pressing plate 5 is connected with the first supporting frame 2 through the first connecting rod 6 and connected with the second supporting frame 3 through the second connecting rod 7 .

[0029] further, such as Figure 7 As shown, in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com