Carrying device

A technology of handling device and handling mechanism, which is applied in the directions of storage device, transportation and packaging, can solve the problems of complex overall structure, high manufacturing cost, and excessive weight of handling device, and achieves simplification of overall structure, weight reduction and manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The detailed features and advantages of the present invention are described in detail below in the embodiments, the content of which is sufficient for any person familiar with the relevant art to understand the technical content of the present invention and implement it accordingly, and according to the contents disclosed in this specification, claims and accompanying drawings, The related objects and advantages of the present invention can be easily understood by anyone skilled in the relevant art. The following examples further illustrate the concept of the present invention in detail, but do not limit the scope of the present invention in any way.

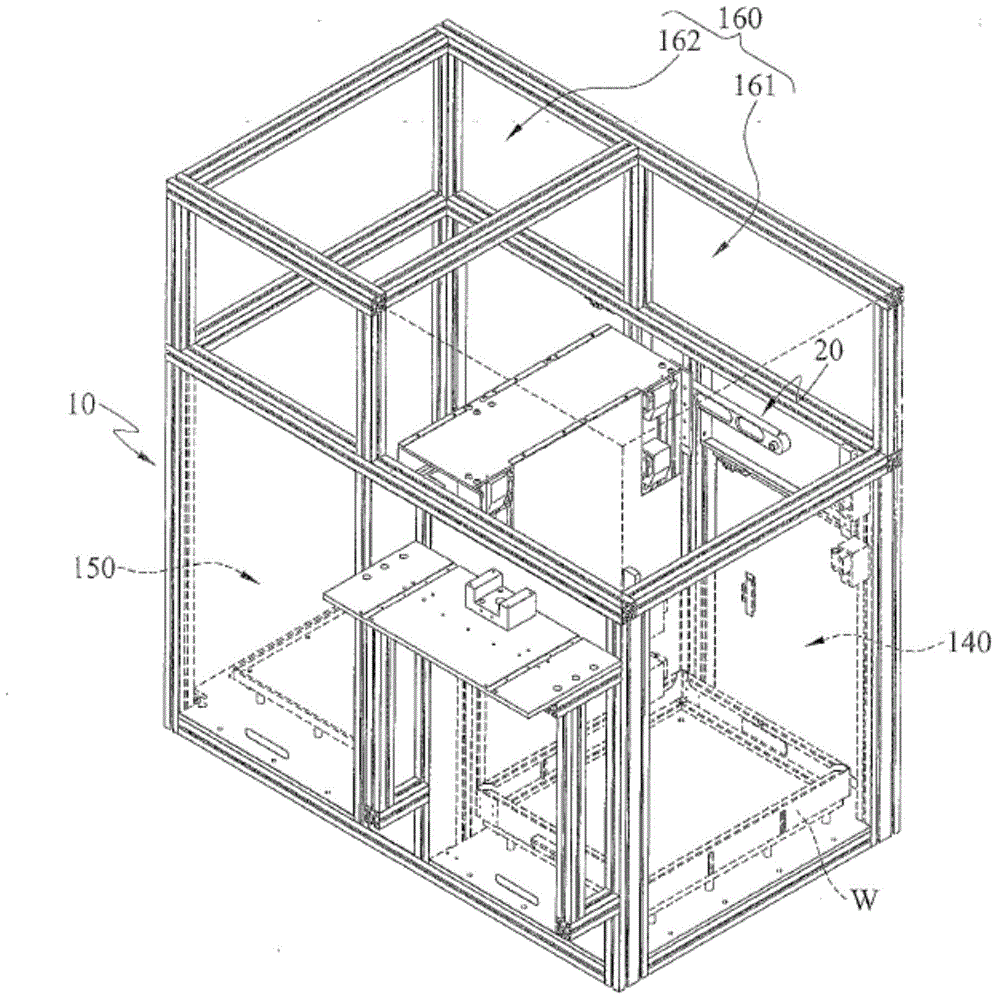

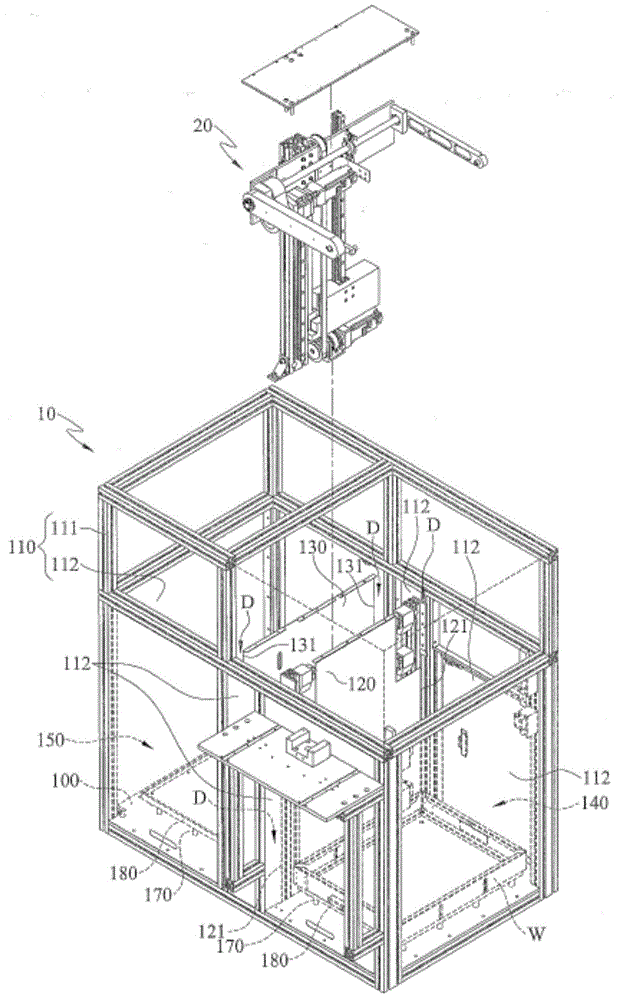

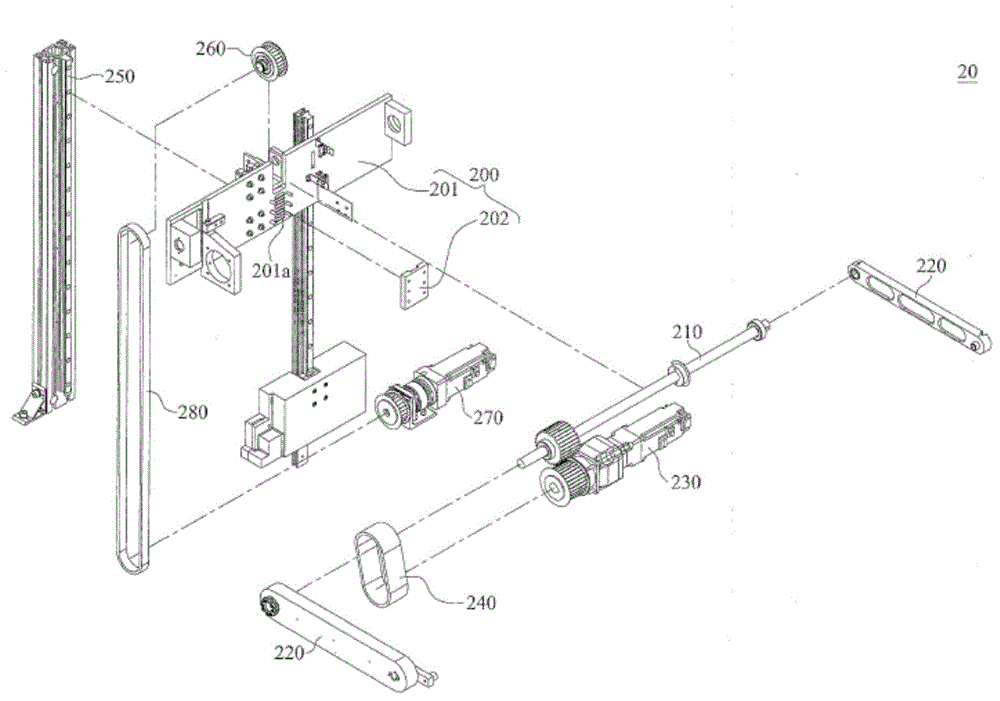

[0049] Please also refer to figure 1 , figure 2 with image 3 . figure 1 It is a three-dimensional schematic diagram of a conveying device according to an embodiment of the present invention. figure 2 It is an exploded schematic diagram of a conveying device according to an embodiment of the present invention. ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com