Secondary rectifying mechanism for combined bag supplier

A bag-feeding machine and bag-feeding technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of skewed and out-of-place material bags, and achieve the effect of simple structure and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

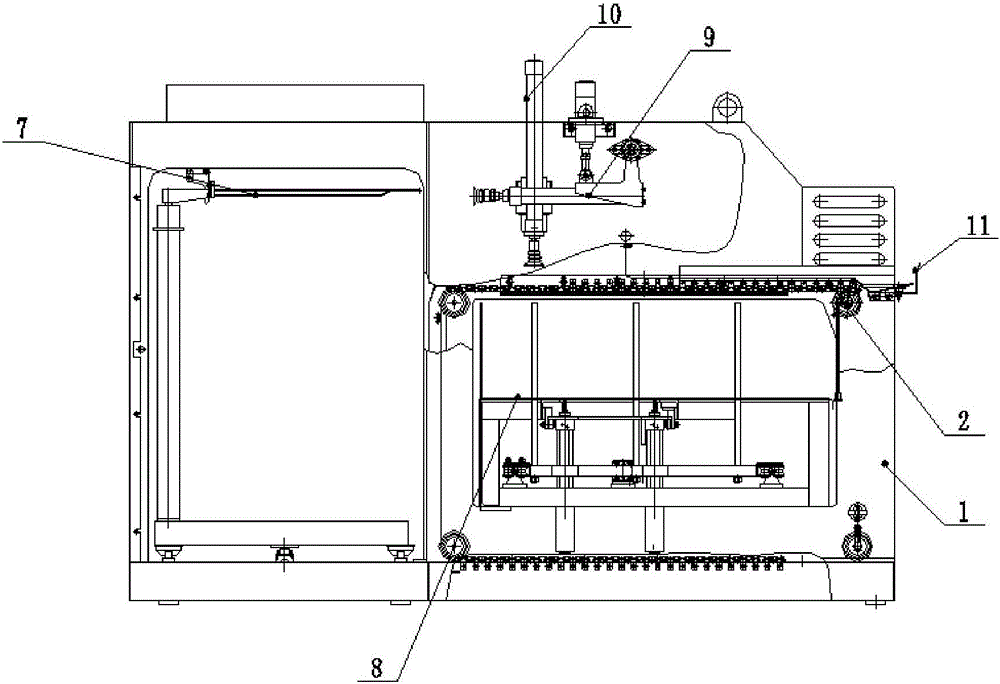

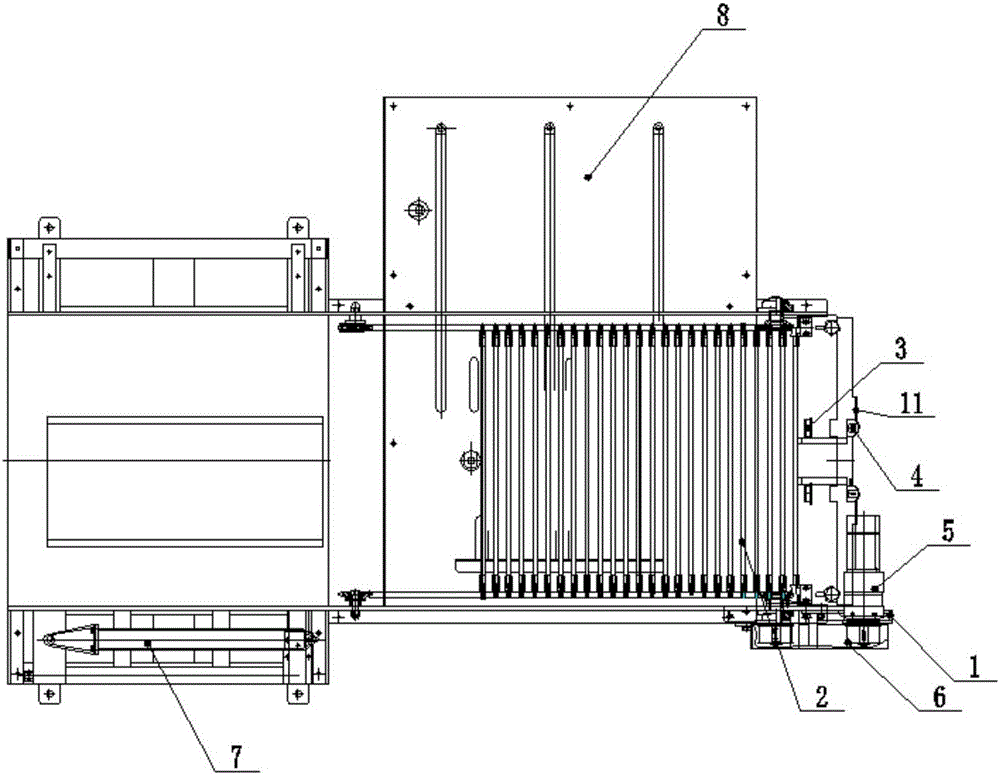

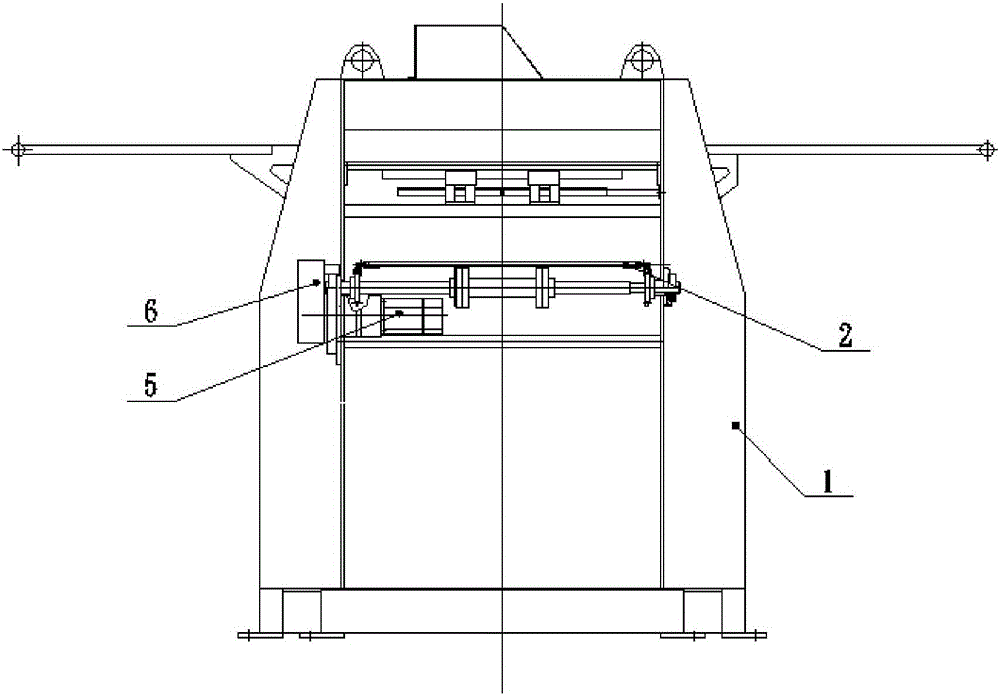

[0012] Referring to the accompanying drawings, a secondary deviation correction mechanism for a combined bag feeding machine includes a frame 1, a vertical bag feeding mechanism 7 mounted on the frame 1 for bag feeding, and a horizontal bag feeding mechanism 8 installed on the machine The vertical bag-taking cylinder 9 and the horizontal bag-taking cylinder 10 for taking bags on the frame 1, the conveyor chain 2 and the conveyor belt assembly 6 installed on the frame 1 for transporting material bags, and the conveyor belt assembly 6 installed on the frame 1 For the motor 5 that drives the conveyor belt assembly 6 to work, a baffle plate 11 is installed on the frame 1 in front of the discharge end of the conveyor chain 2, and two opposite positions are respectively installed on the frame 1 near the discharge end of the conveyor chain 2. Sensor 3, on the frame 1, two deviation correction sensors 4 are respectively installed at positions close to the baffle end 11; a controller is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com