Ship launching fiber-reinforced rubber air bag and molding technique thereof

A fiber-reinforced, rubber airbag technology, applied to berths, ships, hollow objects, etc., can solve the problems of harsh processing environment, poor carrying capacity, and low production efficiency, and achieve excellent processing environment, long service life, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

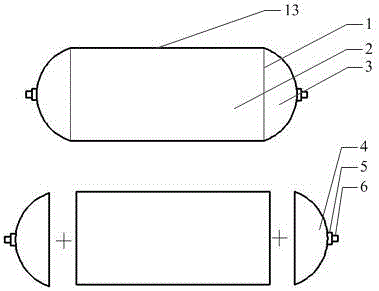

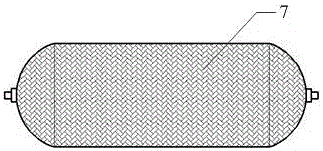

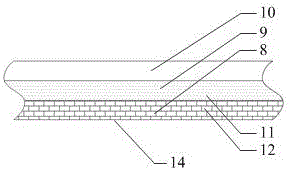

[0021] Embodiment: As shown in the figure, the cylindrical section of the mandrel and the head sections of the two bladders are of equal stress structure, which can realize the overall geodesic winding of the mandrel, and the iron round tube adhered to the mouth of the mandrel at the head is clamped by the chuck. It is convenient to grab the rubber airbag and wind the rubber belt and dry fiber; vulcanize the rubber layer, the fiber reinforced layer and the protective layer wound on the surface of the fiber reinforced layer by multi-layer rubber belt, so as to realize the strengthening of the rubber airbag to bear the stress, and then It can be used for launching ships of higher tonnage. In application, multiple rubber airbags are used to cushion the hull, and the hull can be launched more conveniently by applying thrust to the hull.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com