A plastic waste crushing and mixing frame

A technology for stirring racks and waste products, which is applied in the field of plastic waste crushing and stirring racks, and can solve the problems of poor automation and troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

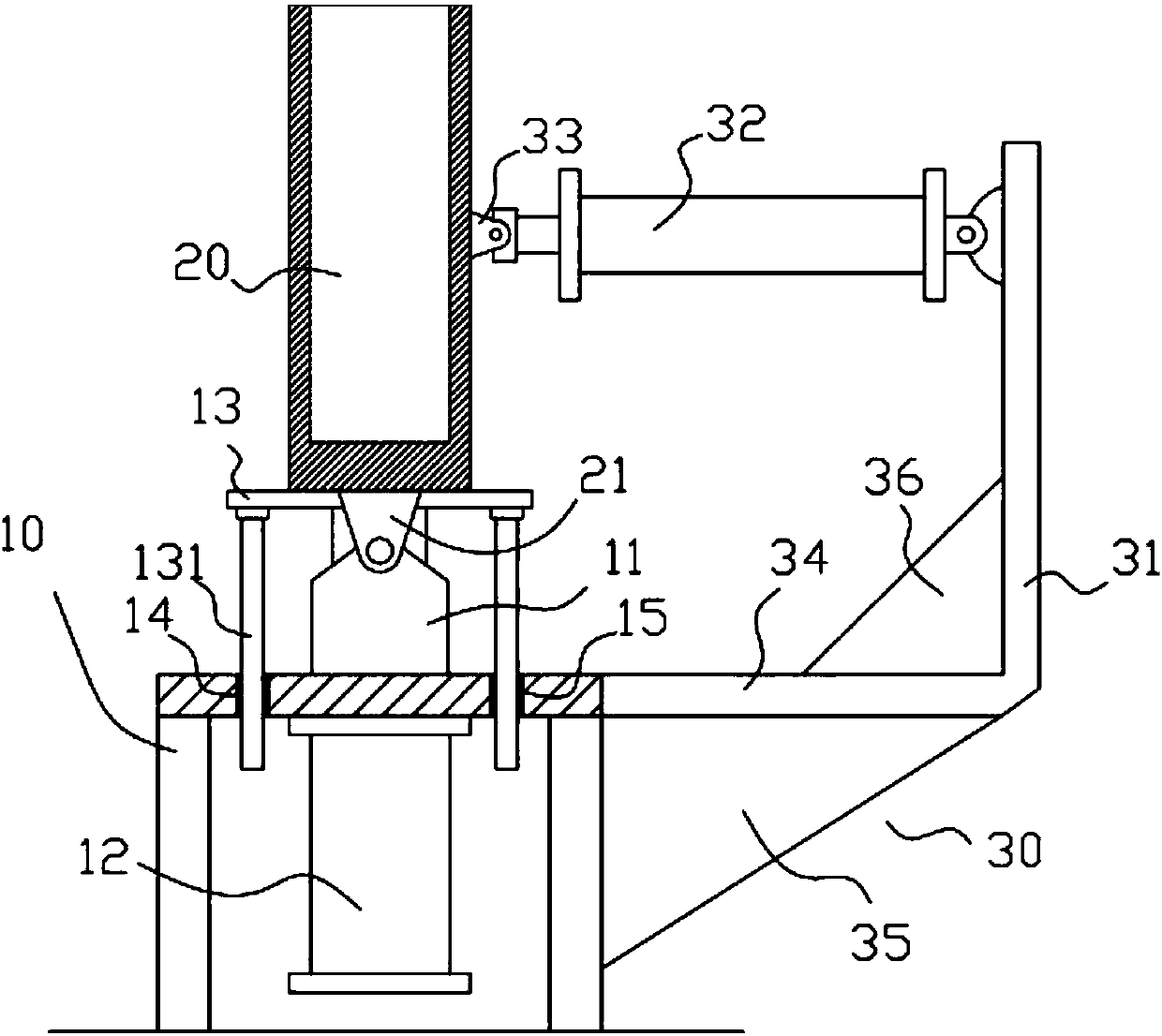

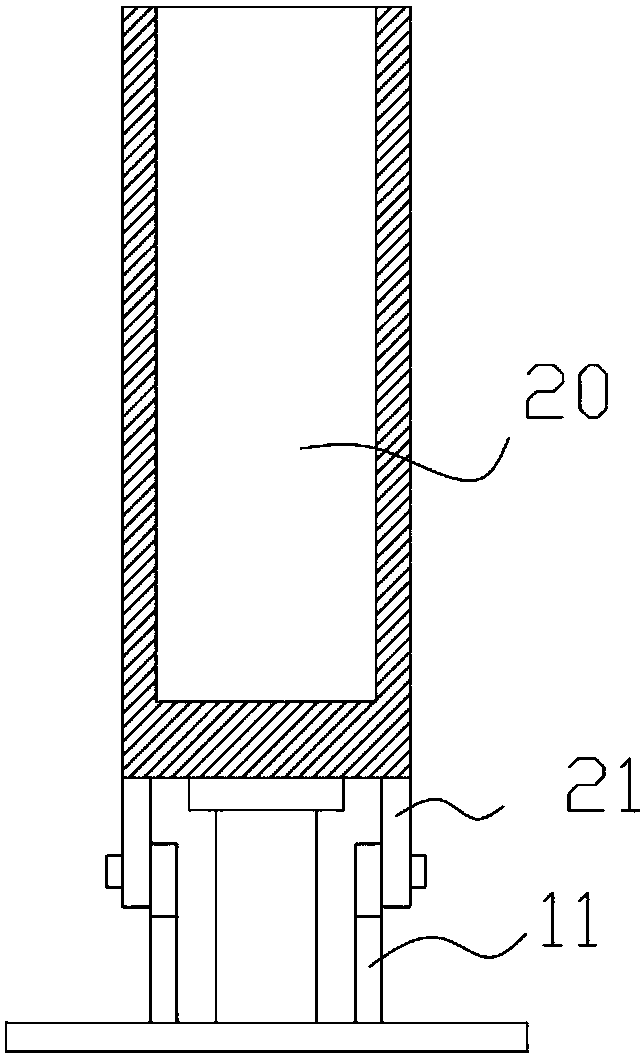

[0016] Example: see Figure 1 to Figure 2 Shown, a kind of plastic waste crushing mixing frame comprises frame body 10, and the middle part of the top surface of the top plate of described frame body 10 is fixed with two supporting plates 11, and the bottom surface of the top plate of frame body 10 is fixed with supporting oil cylinder 12, and supporting oil cylinder The push rod of 12 protrudes upwards from the top plate of the frame body 10 and is fixed with a bottom support plate 13, and the bottom two sides of the crushing bucket body 20 are fixed with connecting blocks 21, and the connecting blocks 21 are hinged on the corresponding support plates 11, and the bottom support plate The body 13 is pressed against the bottom surface of the crushing barrel body 20;

[0017] One side of the frame body 10 is fixed with a connecting frame body 30, a vertical plate body 31 is fixed on the connecting frame body 30, a dumping cylinder 32 is hinged on the vertical plate body 31, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com