Automatic assembling and rivet pressing method and device for cupboard hinge

An automatic assembly and riveting technology, which is applied in the hinge assembly and riveting field, can solve the problems such as the lack of stable and effective control of quality, large cost investment, high cost, etc., to meet the requirements of work ability and ergonomics, Product quality assurance, the effect of improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

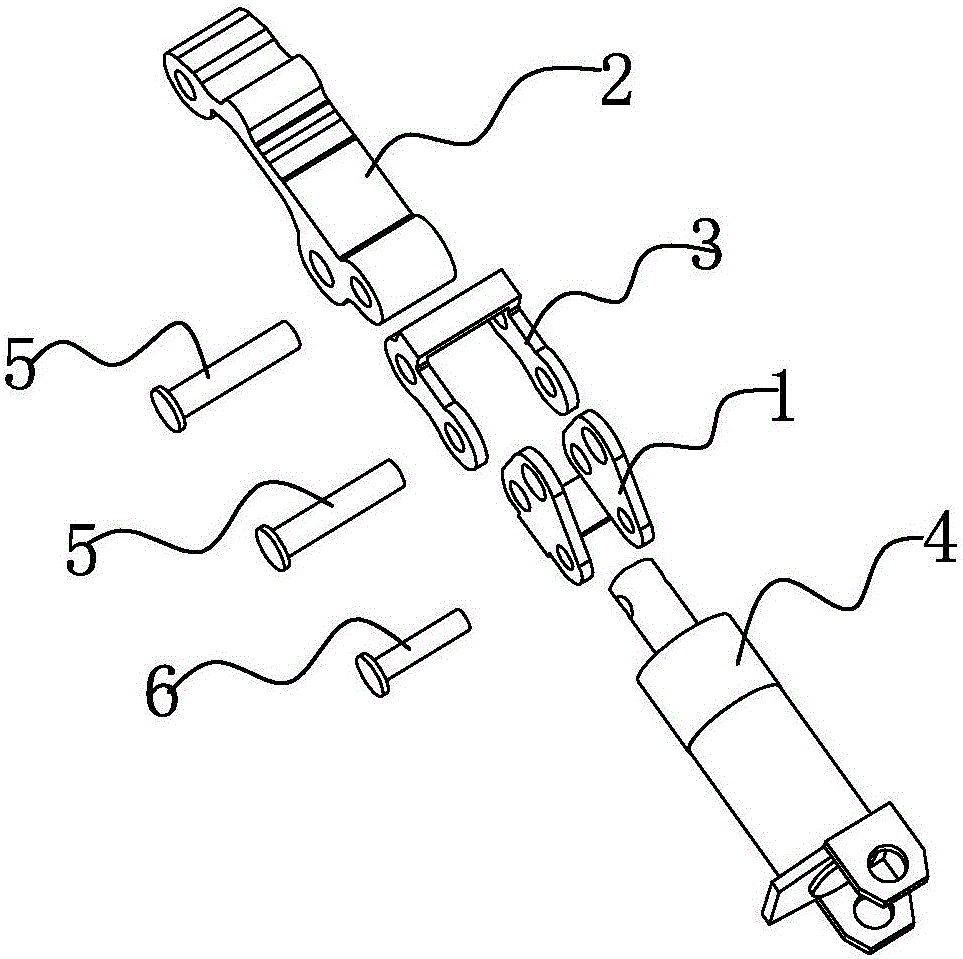

[0047] see Figures 1 to 2 , the cabinet hinge automatic assembly and riveting method provided in this embodiment, the cabinet hinge product assembled with riveting, includes a triangular piece 1, a laminated piece 2, a pull bar 3, a hydraulic tube 4, two long nails 5, a short Nail 6. Wherein, the tie bar 3 and the lamination 2 are provided with corresponding spike holes, through which a spike 5 passes through and are hinged together; The spikes 5 pass through and are hinged together; that is, the brace 3 is provided with two groups of spike holes, corresponding to the spike holes of the lamination 2 and the triangular sheet 1 respectively; the hydraulic pipe 4 and the triangular sheet 1 are provided with corresponding short The nail hole passes through and is hinged by a short nail 6.

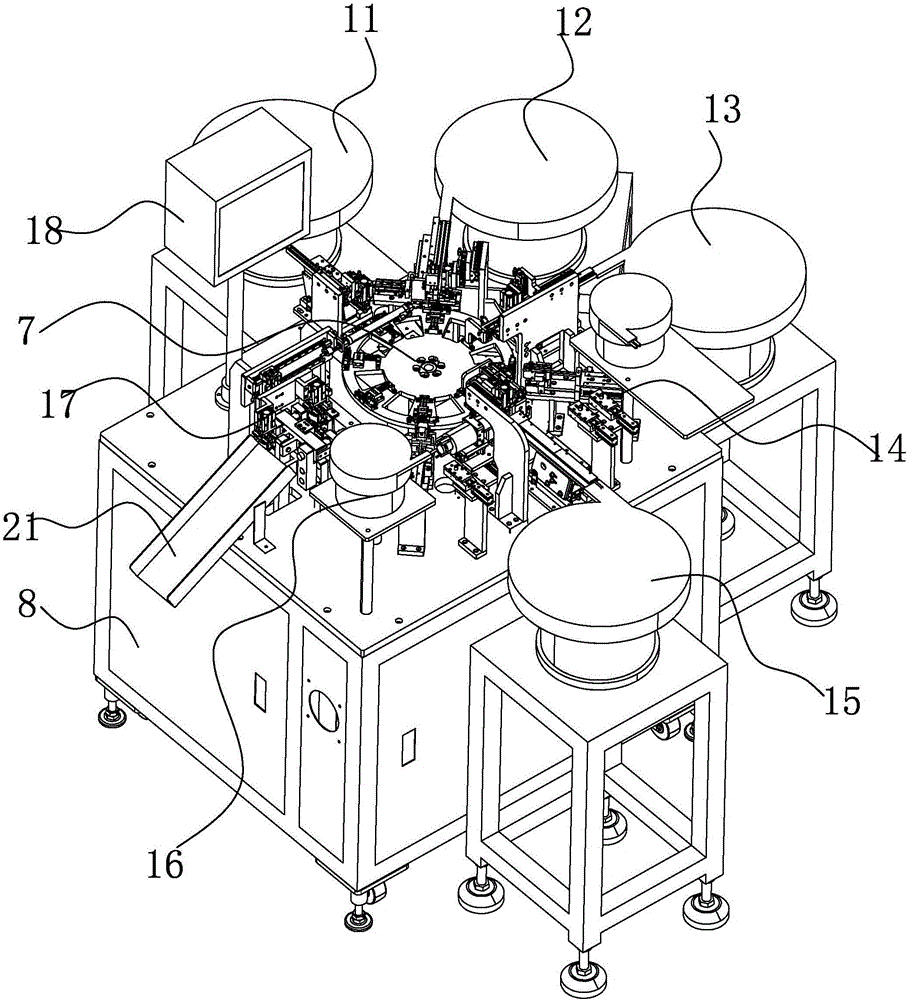

[0048] see Figures 3 to 20 , cabinet hinge automatic assembly riveting method, it comprises the following steps:

[0049] 1) The turntable part 7 is provided, and the turntable part 7 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com