Fixing member, fixing device, and electrophotographic image forming apparatus

A technology of components and molecules, applied in the field of components for electrophotography, to achieve the effect of excellent mutual adhesion and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] (5-1) Step of forming elastic layer of fixing film

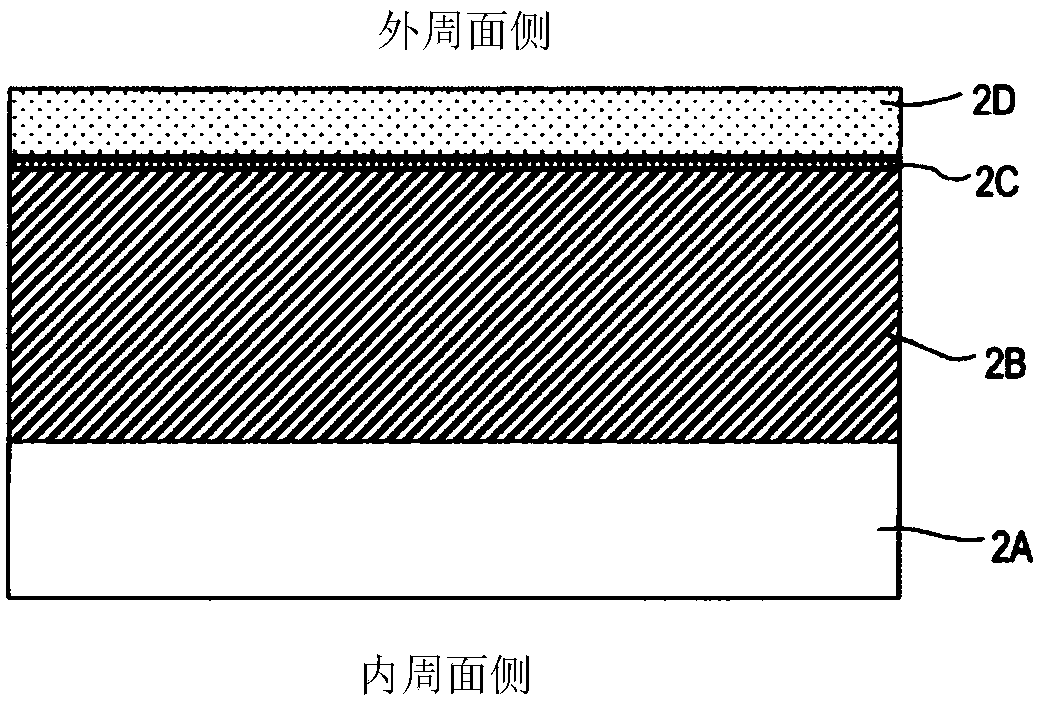

[0135] As the base material 2A having a ring shape, a metal belt made of stainless steel having dimensions of 240 mm in length, 40 μm in thickness, and 30 mm in outer diameter was prepared.

[0136]A rubber-based primer (trade name: X-33-174A, X-33-174B; manufactured by Shin-Etsu Chemical Co., Ltd.) was applied to the outer peripheral surface of the metal belt, leaving 5mm out, so that the coating width is 230mm. The resultant was then placed in an electric furnace and dried at 200° C. for 30 minutes, thereby forming a primer layer. The thickness of the primer layer after drying was set to 2 μm.

[0137] Next, an addition-curable liquid silicone rubber compound for forming the elastic layer 2B was prepared as described below. Specifically, an addition-curable liquid silicone rubber having a methyl group in a side chain (trade name: KE-1281-A, KE-1281-B; manufactured by Shin-Etsu Chemical Co., Ltd.) was prepared. M...

Embodiment 2

[0170] Except in the preparation step of the primer liquid for adhesion, polytetrafluoroethylene (PTFE) was used as the fluororesin instead of tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer (PFA), and in the release layer 2D In the formation step of , except that the PFA dispersion liquid was changed to a PTFE dispersion liquid (trade name: 852N-201; manufactured by Du Pont-Mitsui Fluorochemicals Company, Ltd.), the same method as in Example 1 was produced according to Example 2. Fixing film. The thickness of the release layer was found to be 15 μm.

[0171] The fixing film was subjected to a durability test in the same manner as in Example 1.

[0172] In addition, the fixing film was subjected to a 100,000-sheet durability test in the same manner as in Example 1, and then the mutual adhesion between the release layer and the elastic layer was evaluated. In addition, FT-IR measurement was performed in the same manner as in Example 1 on the peeled surface. The resu...

Embodiment 3

[0174] Except in the preparation step of primer liquid for adhesion, tetrafluoroethylene-hexafluoropropylene copolymer (FEP) is used as fluororesin instead of tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer (PFA), and In the forming step of the release layer 2D, except that the PFA dispersion was changed to the FEP dispersion (trade name: 856N-200; manufactured by Du Pont-Mitsui Fluorochemicals Company, Ltd.), in exactly the same manner as in Example 1 A fixing film according to Example 3 was produced. The thickness of the release layer was found to be 15 μm.

[0175] The fixing film was subjected to a durability test in the same manner as in Example 1.

[0176] In addition, the fixing film was subjected to a 100,000-sheet durability test in the same manner as in Example 1, and then the mutual adhesion between the release layer and the elastic layer was evaluated. In addition, FT-IR measurement was performed in the same manner as in Example 1 on the peeled surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com