Anti-cracking pintype insulator

A pin-type insulator and anti-explosion technology, applied in the direction of pin-type insulators, etc., can solve the problems of cracking in the groove of the porcelain body, affecting the use of the insulator, etc., and achieve the effect of preventing expansion and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

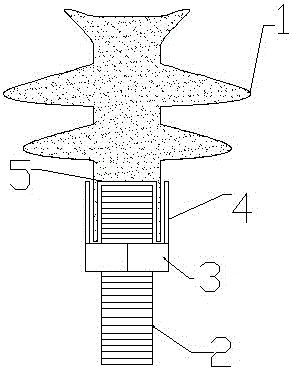

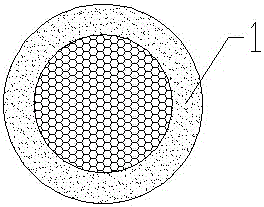

[0014] Such as figure 1 Shown: an anti-explosion pin type insulator, including a porcelain body 1, a screw column 2, and a nut 3, the lower end of the porcelain body 1 is provided with a groove 5, and the screw column 2 is inserted into the groove at the lower end of the porcelain body 1 In 5, an adhesive is used for bonding and connection, and the nut 3 is connected to the screw post 2 .

[0015] Further speaking, the nut 3 is welded with an annular cylinder 4 .

[0016] Further speaking, the diameter of the circular cylinder 4 is 2 mm larger than the edge diameter of the groove 5 at the lower end of the porcelain body 1 .

[0017] Furthermore, the material of the circular cylinder 4 is iron or aluminum alloy.

[0018] When the present invention is in use: the groove of the porcelain body and the screw column are bonded and fixed with an adhesive, the nut welded with the circular cylinder is connected with the end of the screw column, and the nut is turned to make the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com