Multi-layer composite floor and production method thereof

A multi-layer compounding and production method technology, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of floor strength, texture and hand feeling that cannot be compared with solid wood floors, etc., and achieve high structure Strength and overall stability, high dimensional stability, not easy to warp and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

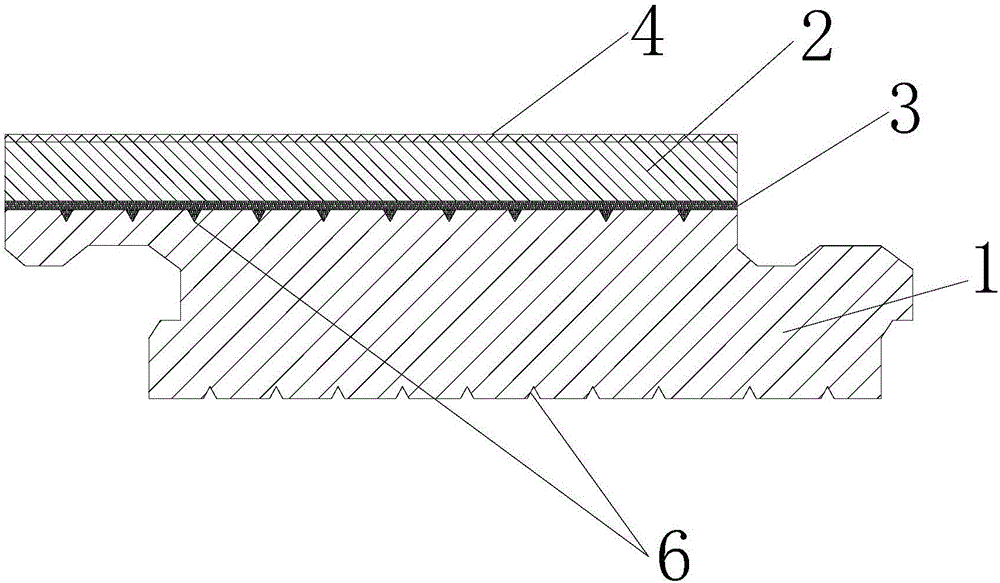

[0025] Embodiment 1: a kind of multi-layer composite floor, such as figure 1 Shown: include PVC base material layer 1, the upper surface of PVC base material layer 1 is provided with skin layer 2, is provided with paint layer 4 on the skin layer 2, and described skin layer 2 is wood veneer or bamboo skin, and described skin layer 2 A polyurethane adhesive layer 3 is provided between the PVC substrate layer 1 . Both the upper surface and the lower surface of the PVC substrate layer 1 are provided with a plurality of V-shaped grooves 6 along the length direction of the floor. The opening angle of the V-shaped grooves 6 is 25-50°, the depth is 1.5mm-2.5mm, and the distance between each V-shaped groove 6 is 12mm-35mm. The PVC substrate layer 1 is a PVC foam material layer. The thickness ratio of the skin layer 2 to the PVC base layer 1 is 1:3 to 1:5.

[0026] The production method of the aforementioned multilayer composite floor specifically comprises the following steps:

[0...

Embodiment 2

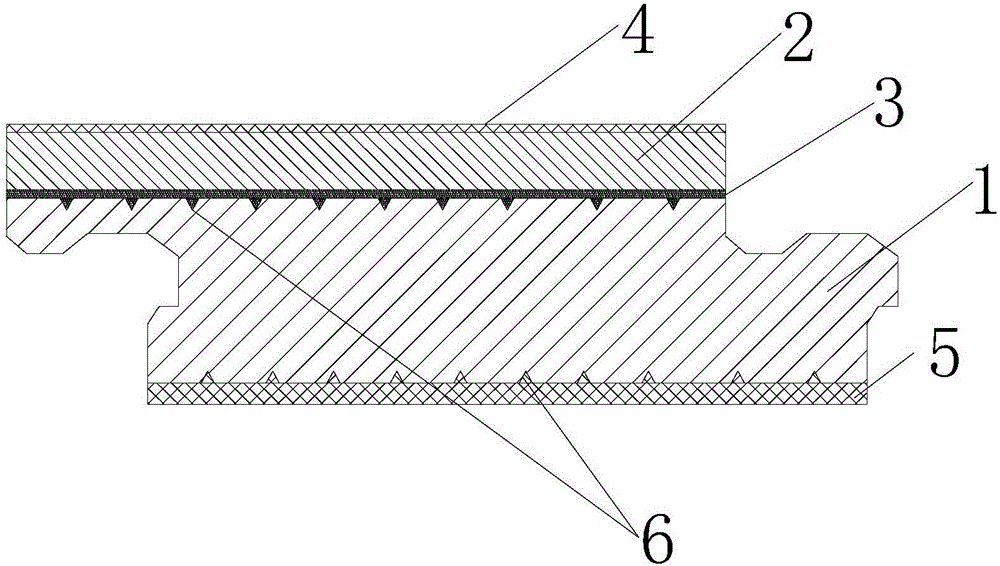

[0034] Embodiment 2. A kind of multi-layer composite floor, such as figure 2 Shown: include PVC base material layer 1, the upper surface of PVC base material layer 1 is provided with skin layer 2, is provided with paint layer 4 on the skin layer 2, and described skin layer 2 is wood veneer or bamboo skin, and described skin layer 2 A polyurethane adhesive layer 3 is provided between the PVC substrate layer 1 . The lower surface of the PVC substrate layer 1 is provided with an EVA bottom layer 5 of 3 mm to 5 mm. Both the upper surface and the lower surface of the PVC substrate layer 1 are provided with a plurality of V-shaped grooves 6 along the length direction of the floor. The opening angle of the V-shaped grooves 6 is 25-50°, the depth is 1.5mm-2.5mm, and the distance between each V-shaped groove 6 is 12mm-35mm. The PVC substrate layer 1 is a PVC foam material layer. The thickness ratio of the skin layer 2 to the PVC base layer 1 is 1:3 to 1:5.

[0035] The production ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com