High-strength specially-shaped welding-free pipe

A high-strength, special-shaped technology, applied in the direction of building types, fences, roads, etc., can solve the problems of poor stability of the rectangular cavity structure, low production efficiency, distortion and deformation, etc., to prevent distortion or fracture, and high production efficiency , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

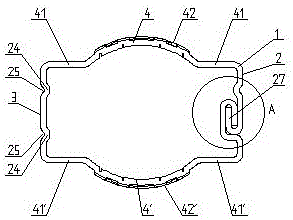

[0025] Such as Figure 1~Figure 6 Among them, the high-strength special-shaped welding-free pipe material, the pipe material 1 includes a closed surface 2, a corresponding surface 3, a tension surface 4, 4', and the tension surface 4, 4' is connected to the closed surface 2 and the corresponding surface 3 respectively to form a hollow cavity Body, the stability of the structure of the present invention is good.

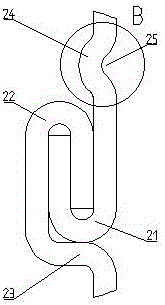

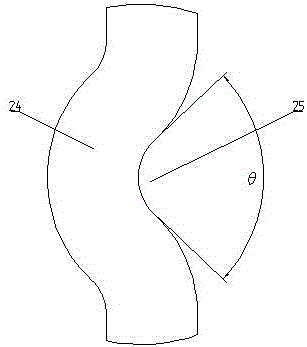

[0026] Such as figure 1 , figure 2 Among them, the sealing surface 2 is provided with at least one boss 27 and a displacement limiting section 23 inside the cavity; the boss 27 is formed by the first U-shaped mouth 21 and the second U-shaped mouth 22, and the indent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com