Cold head for cryogenic refrigerating machine

A refrigeration refrigeration and cold head technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve problems such as performance loss, and achieve the effect of reducing costs and reducing the risk of oil penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

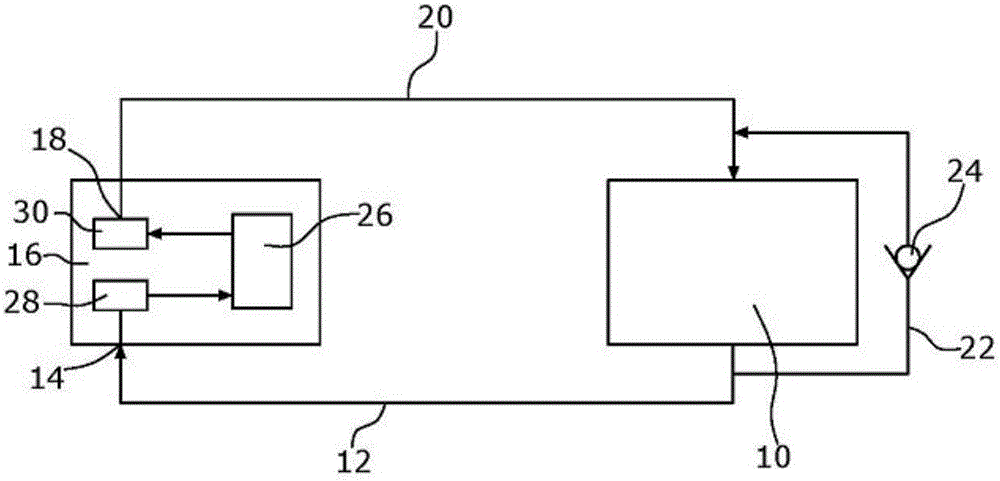

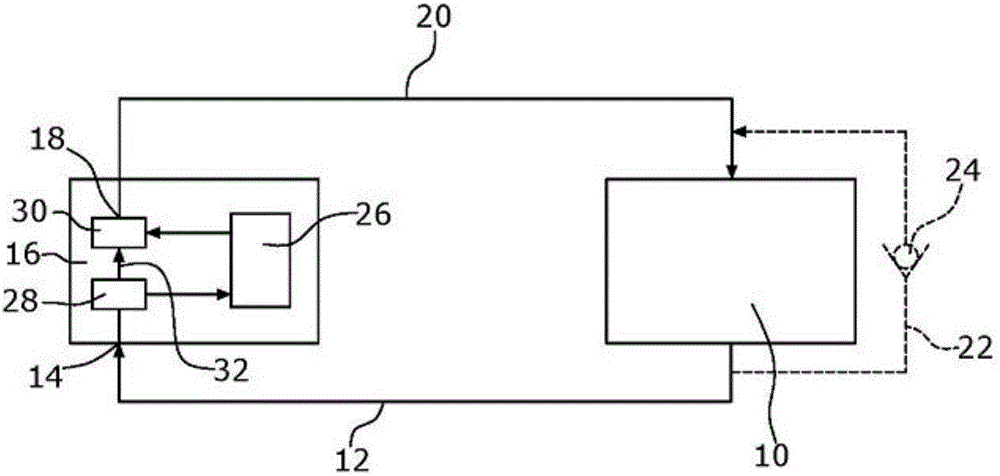

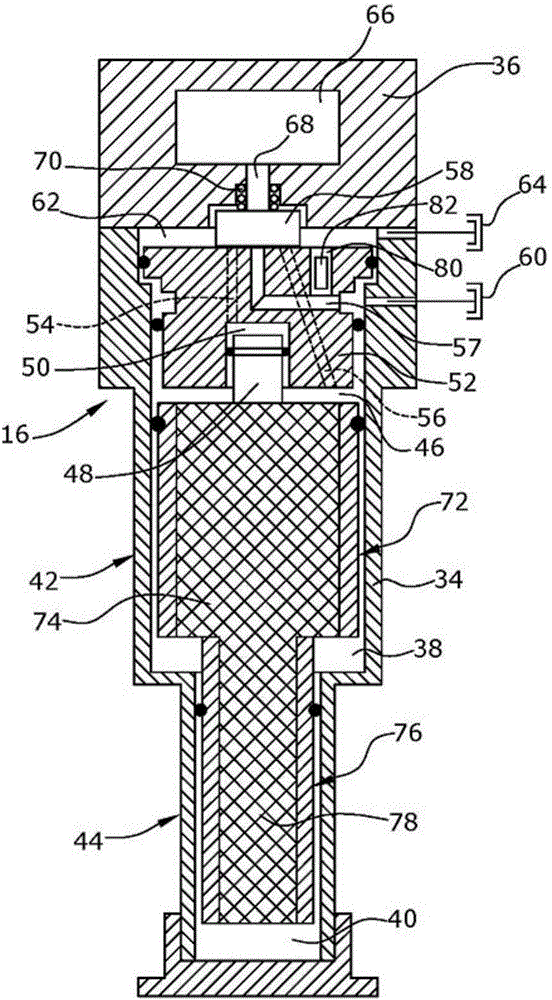

[0016] The refrigerated refrigerator of the prior art ( figure 1 ) includes a compressor 10 that compresses a refrigerant such as helium. On the high pressure side, the compressor 10 is connected via a conduit 12 to a high pressure connection 14 of a cold head 16 . The low pressure connection 18 of the cold head 16 is connected to the low pressure side of the compressor 10 via a conduit 20 . In order to avoid overloading on the compressor 10 , a check valve 24 is arranged in the return line 22 which connects the high-pressure side of the compressor 10 to the low-pressure side of the compressor 10 .

[0017] Within the cold head 16 a working chamber 26 is provided in which the figure 1 Displacer piston not shown. An inlet valve 28 is connected to the high pressure connection 14 such that compressed refrigerant flows into the working chamber 26 when the inlet valve 28 is open. The expanded refrigerant may be directed to the low pressure connection 18 via a discharge valve 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com