The Design Method of the Root Thickness of the End-Contacted Few Parabolic Parabolic Variable Section Auxiliary Springs

A technology of root thickness and parabola, applied in the direction of leaf springs, springs, calculations, etc., can solve the problems of complex analysis and calculation of internal force of main and auxiliary springs, failure to meet design requirements, failure to give design methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

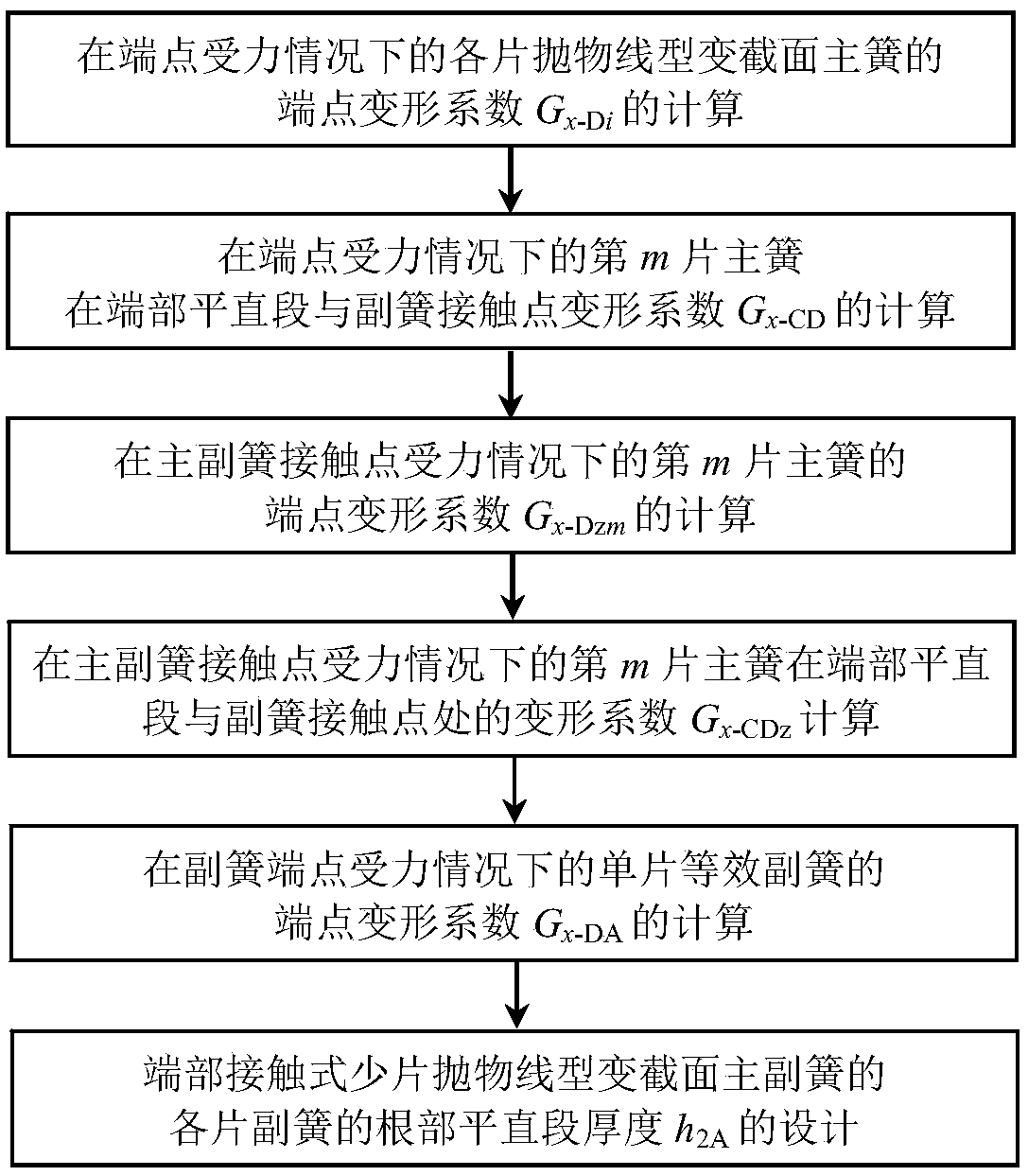

Method used

Image

Examples

Embodiment 1

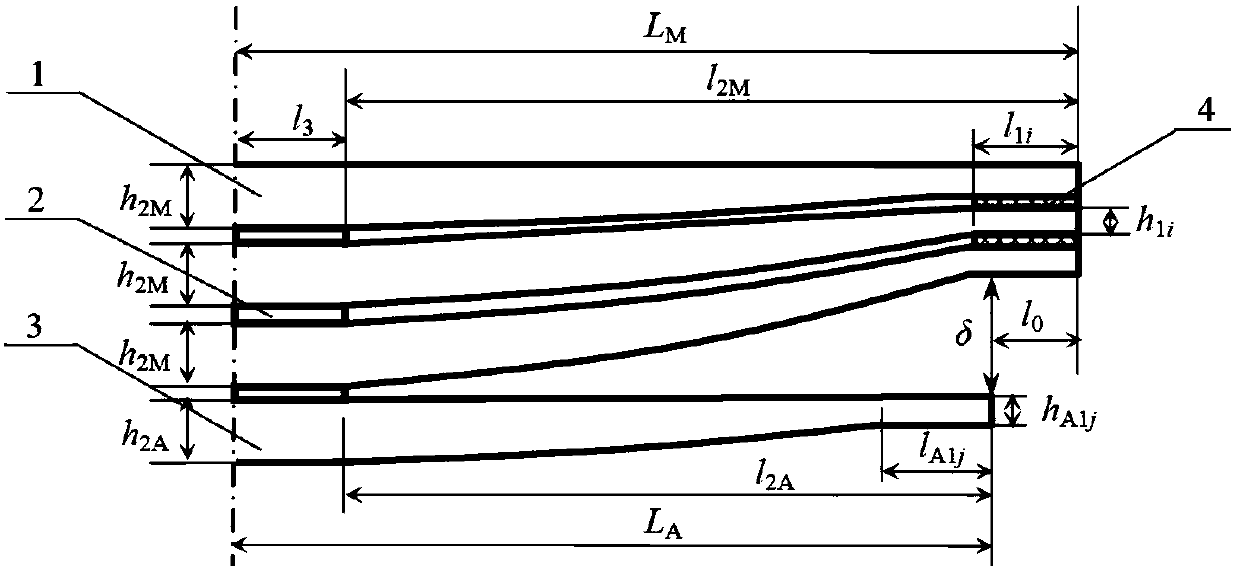

[0032] Embodiment 1: The width of the primary and secondary springs of a few-piece parabolic variable-section contact type at the end is b=60mm, the modulus of elasticity E=200GPa, half of the installation distance l 3 =55mm; Among them, the number of main reeds m=2, half the length L of each main spring M =575mm, the thickness h of the straight section at the root 2M =11mm, the horizontal distance l from the root of the parabola segment to the end point of the main spring 2M = L M -l 3 =520mm; Thickness h of the straight section at the end of the first main spring 11 =7mm, the thickness ratio of the parabolic segment of the first main spring to β 1 = h 11 / h 2M =0.64; the thickness h of the straight section at the end of the second main spring 12 = 6mm, the thickness ratio of the parabolic segment of the second main spring to β 2 = h 12 / h 2M = 0.55. The number of sheets of the auxiliary spring n=1, half the length L of the auxiliary spring A =525mm, the horizonta...

Embodiment 2

[0055] Embodiment 2: The width of the primary and secondary springs of a few-piece parabolic variable cross-section contact type at the end is b=60mm, the modulus of elasticity E=200GPa, half of the installation distance l 3 =60mm; Among them, the number of main reeds m=2, half the length L of each main spring M =600mm, the thickness h of the straight section at the root of the main spring 2M =12mm, the horizontal distance l from the root of the parabola segment to the end point of the main spring 2M = L M -l 3 =540mm; Thickness h of the straight section at the end of the first main spring 11 = 8mm, the thickness ratio of the parabolic segment of the first main spring to β 1 = h 11 / h 2M =0.67; the thickness h of the straight section at the end of the second main spring 12 =7mm, the thickness ratio of the parabolic segment of the second main spring to β 2 = h 12 / h 2M = 0.58. Number of secondary reeds n=1, half length L of secondary reeds A =540mm, the horizontal d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com