Guide rail assembling technological method for large composite box

A technology of composite materials and assembly technology, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems that cannot be used as assembly benchmarks, high equipment prices, and affect assembly efficiency, etc., and achieve convenient and fast rail parallelism and height Poor dimensional accuracy measurement, high-precision and low-cost measurement, and the effect of achieving high-precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

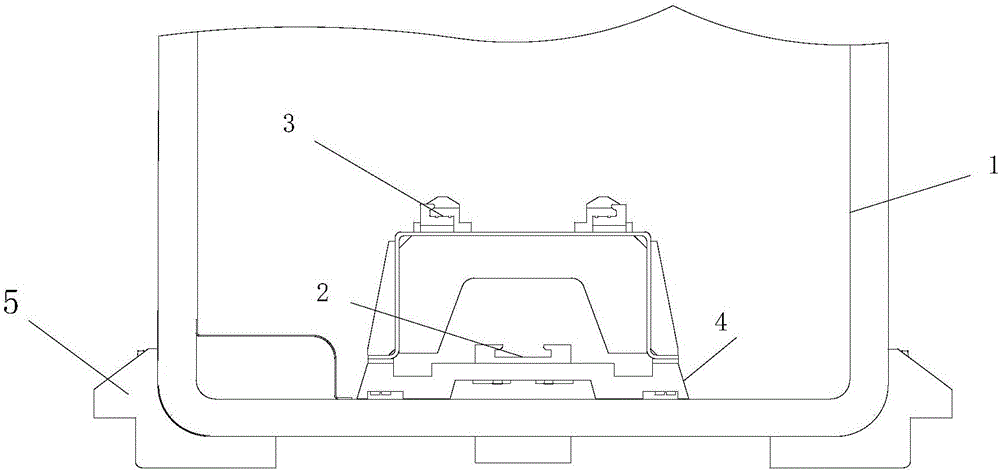

Image

Examples

Embodiment

[0047] Step (1), assembly datum determination

[0048] When assembling, place the bottom corner fittings of the composite material box on the assembly platform to ensure that there is no gap between the bottom corner fittings and the assembly platform, so that the assembly platform is regarded as the only benchmark for the assembly of the front and rear guide rails.

[0049] Step (2), bottom corner fitting assembly

[0050] Through the optimization of the installation process of the corner pieces, the height of the two bottom corner pieces at the front end of the box body is processed to 46.5mm, and the height of the two corner pieces at the rear end is 45mm. Adjust the flatness of the four corner pieces to 0.2mm by means of glass cloth to ensure that the bottom surface of the bottom corner piece is parallel to the bottom surface of the box inner cavity, effectively eliminating the influence of the tip and deflection deformation of the box.

[0051] Step (3), horizontally arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com