Seawater hydraulic proportional flow control valve

A flow control valve, hydraulic technology, applied in the direction of sliding valves, valve details, valve devices, etc., to solve sealing problems, improve control accuracy, and improve the effect of dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

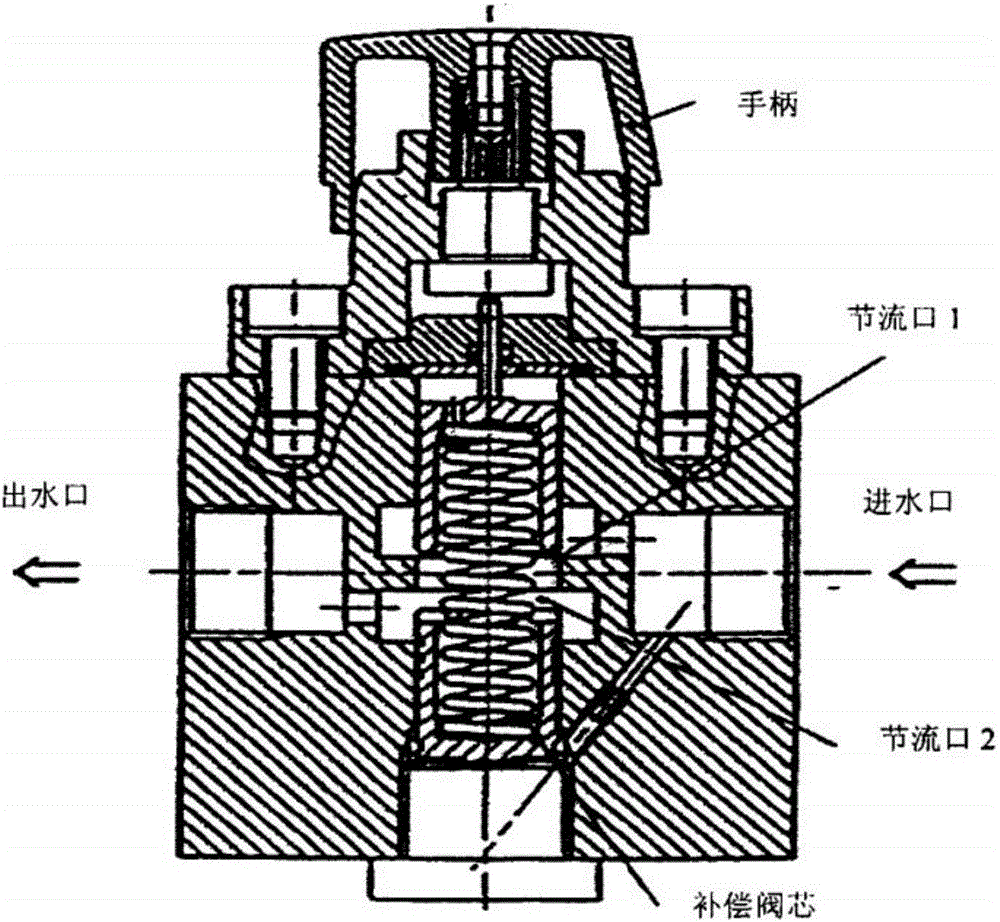

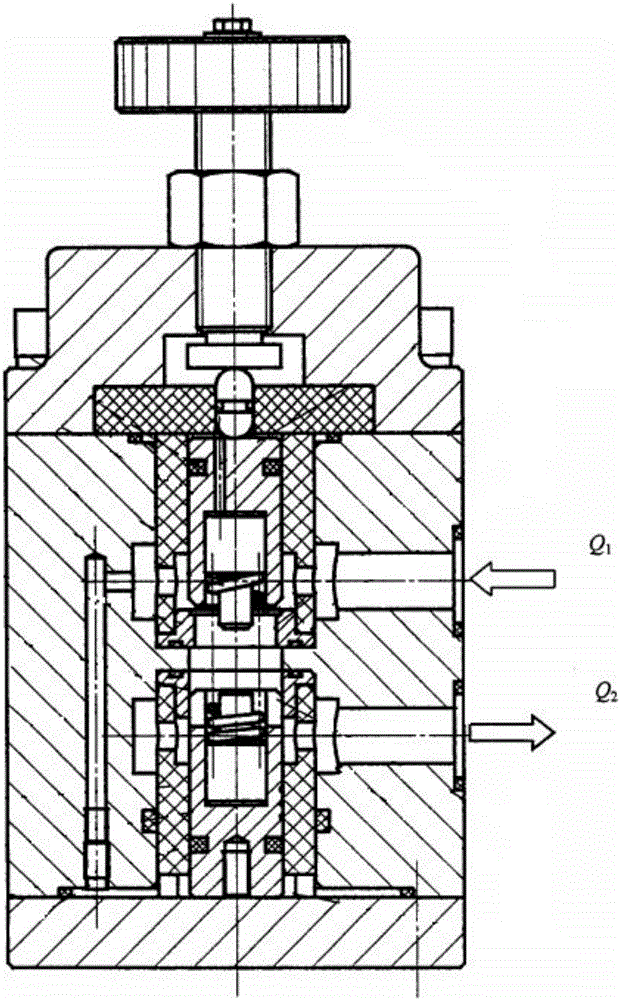

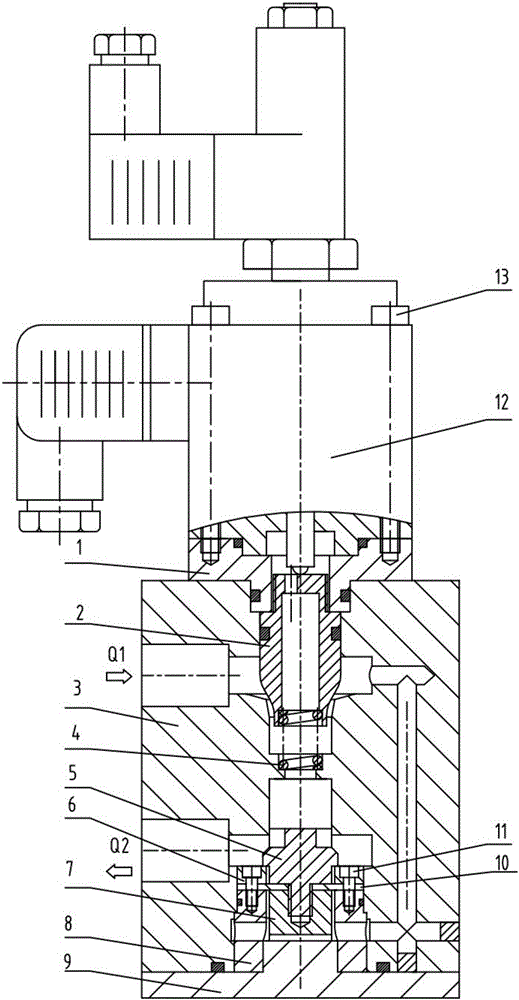

[0025] The invention discloses a seawater hydraulic proportional flow control valve, the specific implementation of which is as follows:

[0026] Input a given electric signal, the electromagnetic thrust generated by the proportional electromagnet 12 with a displacement sensor acts on the upper end of the upper valve core 2 through the push rod, and the upper valve core 2 overcomes the spring force and friction force under the action of the electromagnetic force and moves to the corresponding position, the displacement sensor will detect the actual position of the upper spool 2, and feed back the detected position signal to the control system, and the control system will correct the deviation from the given input value in time to make the upper spool 2 move to the adjusted position Set the position so that the upper orifice maintains the corresponding opening. At this time, the action of the lower valve core on the diaphragm 10 is at zero position, and the lower throttle port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com