Unitized porcelain panel curtain wall

A unitary, ceramic plate technology, applied to walls, buildings, building components, etc., can solve the problems of poor safety and heavy weight, and achieve the effects of improving installation accuracy, convenient installation, and reducing the amount of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

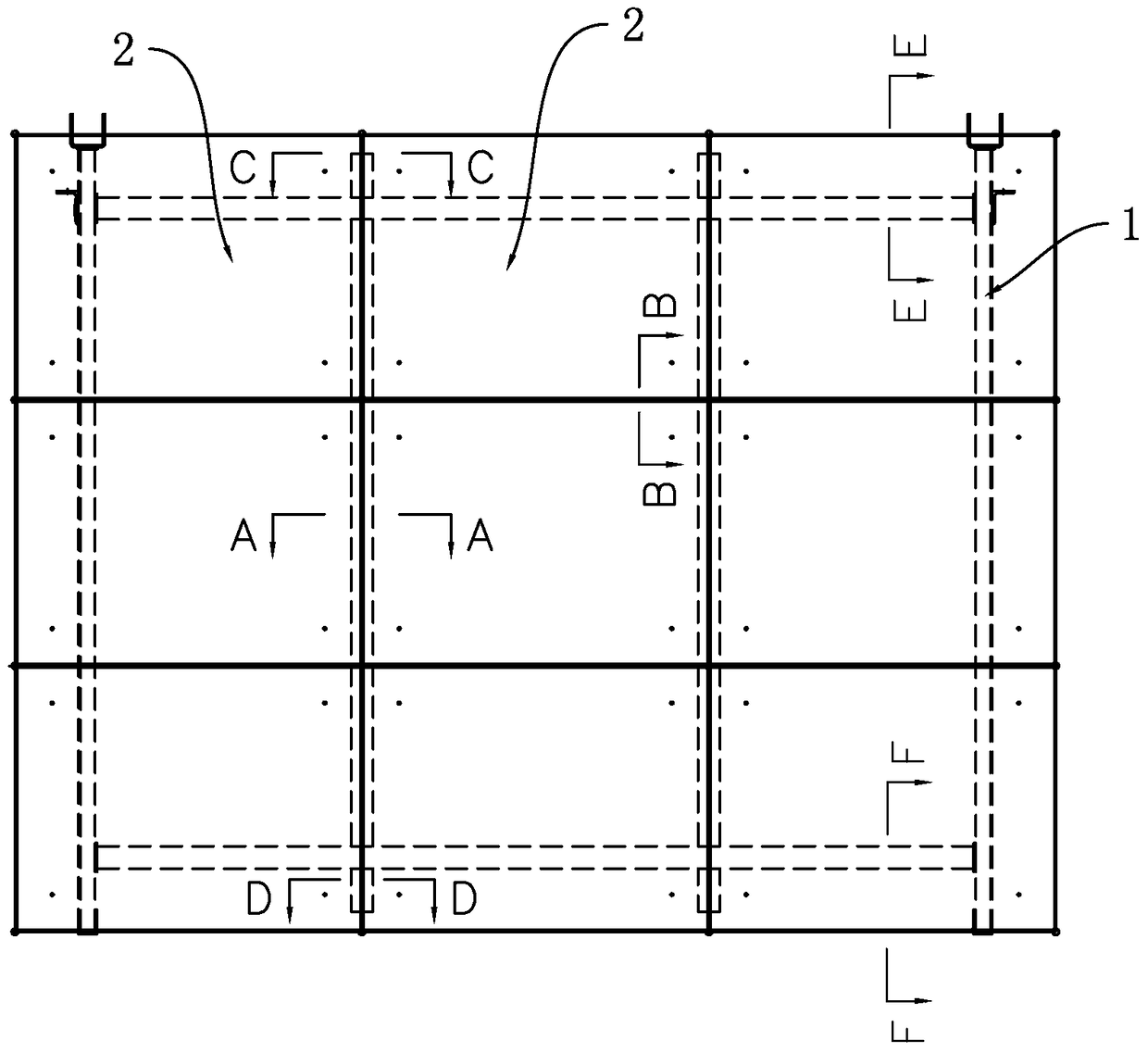

[0025] The first embodiment, such as Figure 1 to Figure 10 As shown, a unit type porcelain panel curtain wall includes a plurality of porcelain panel units 2, a frame 1, a number of connecting pieces 3, a fixed plate 21 and a supporting keel 4.

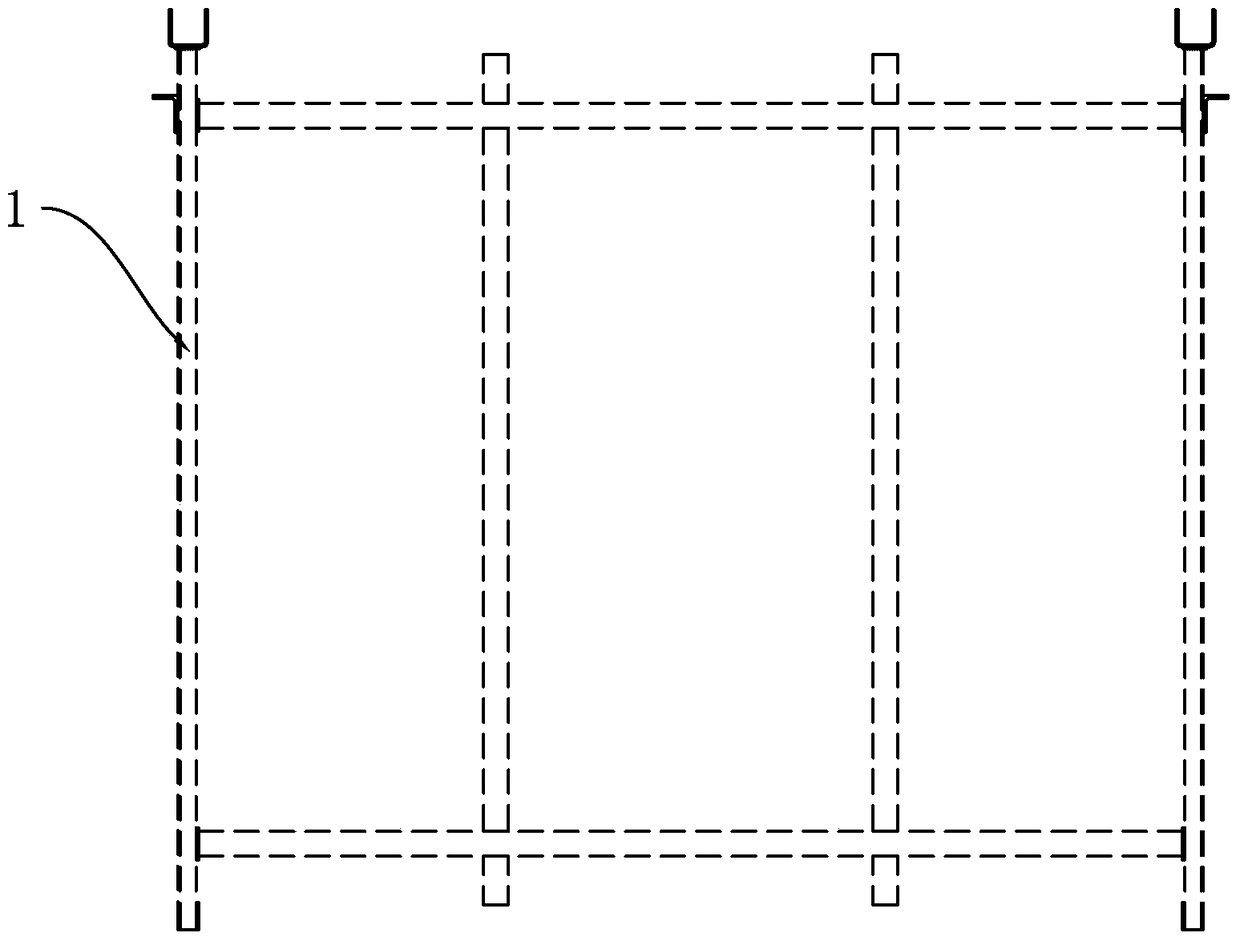

[0026] See figure 1 with figure 2 , The frame 1 is divided into a number of unit frames for accommodating the porcelain plate unit 2 by its horizontal and vertical frames.

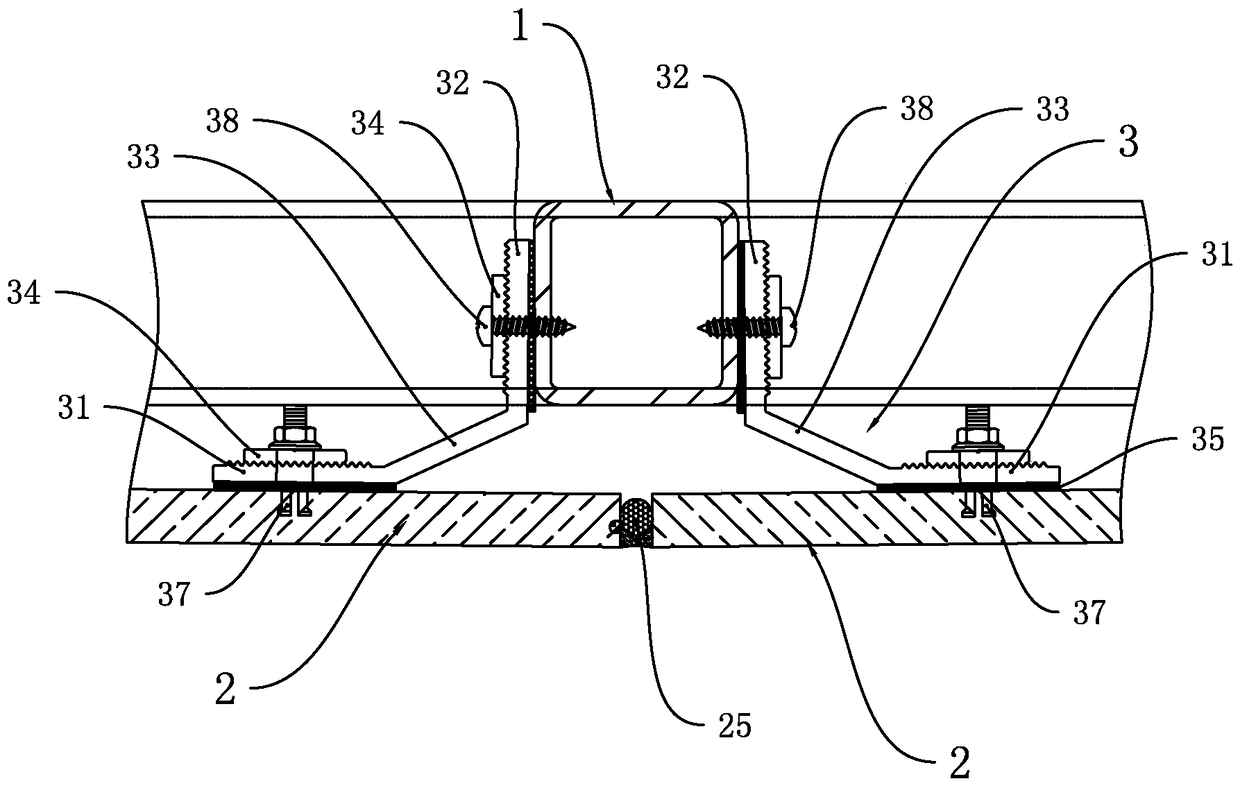

[0027] See image 3 with Figure 4 The connecting member 3 includes a first mounting plate 31 connected with the porcelain plate unit 2, a second mounting plate 32 connected with the frame of the frame 1, and a connecting plate 33 connecting the first mounting plate 31 and the second mounting plate 32. The first mounting plate 31 and the second mounting plate 32 are perpendicular to each other. The first mounting plate 31 is provided with a first round hole. A back bolt 37 passes through the first round hole to fix the first mounting plate 31 and the porcelain plate u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com