Construction method for digging pile foundation hole manually

A construction method and pile foundation hole technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of difficult to use high-stress rock formation, rock mass disturbance and adverse environmental impact, so as to reduce disturbance and environmental impact. Influence, convenient and labor-saving construction operation, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

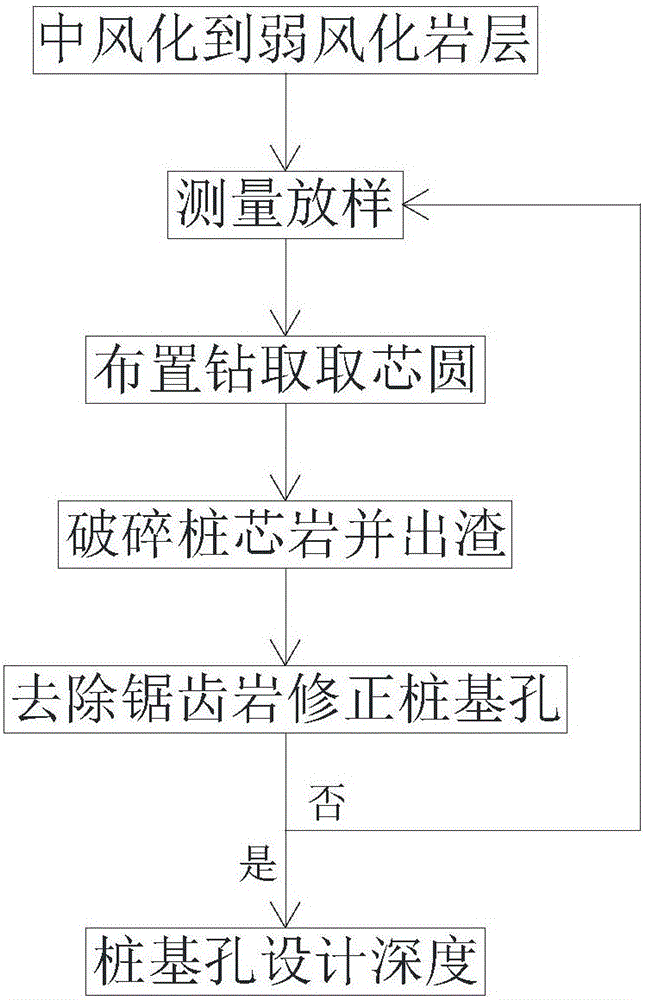

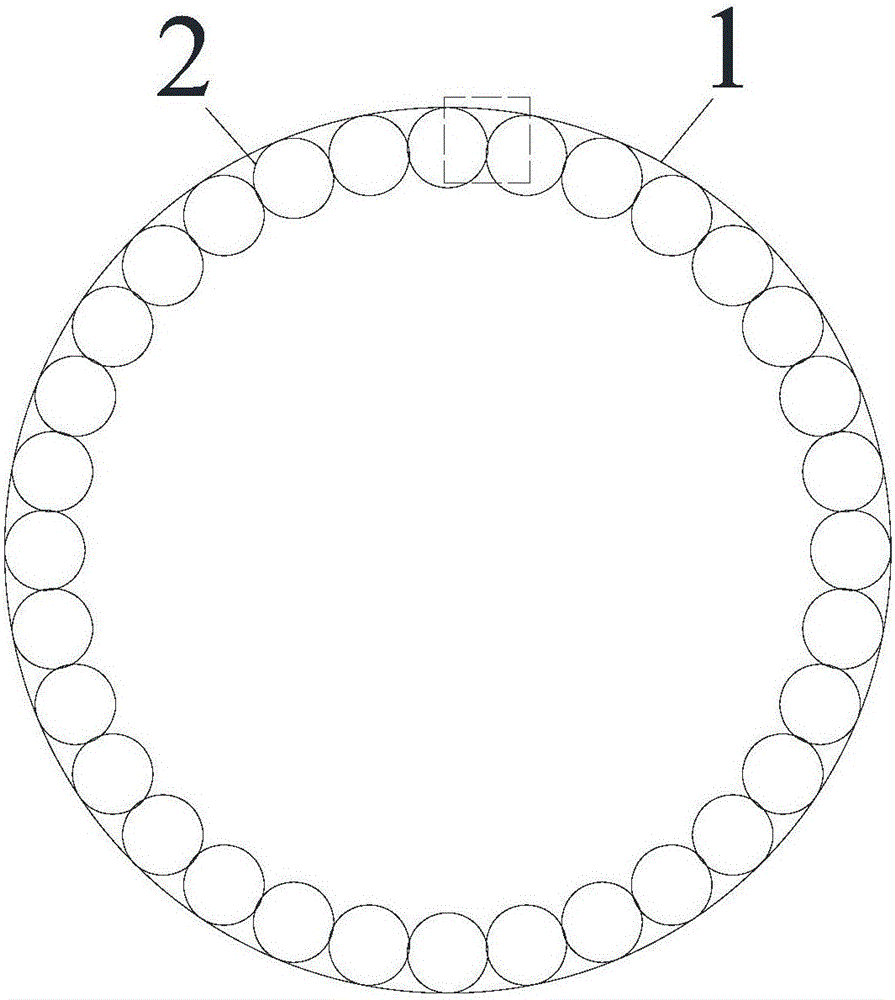

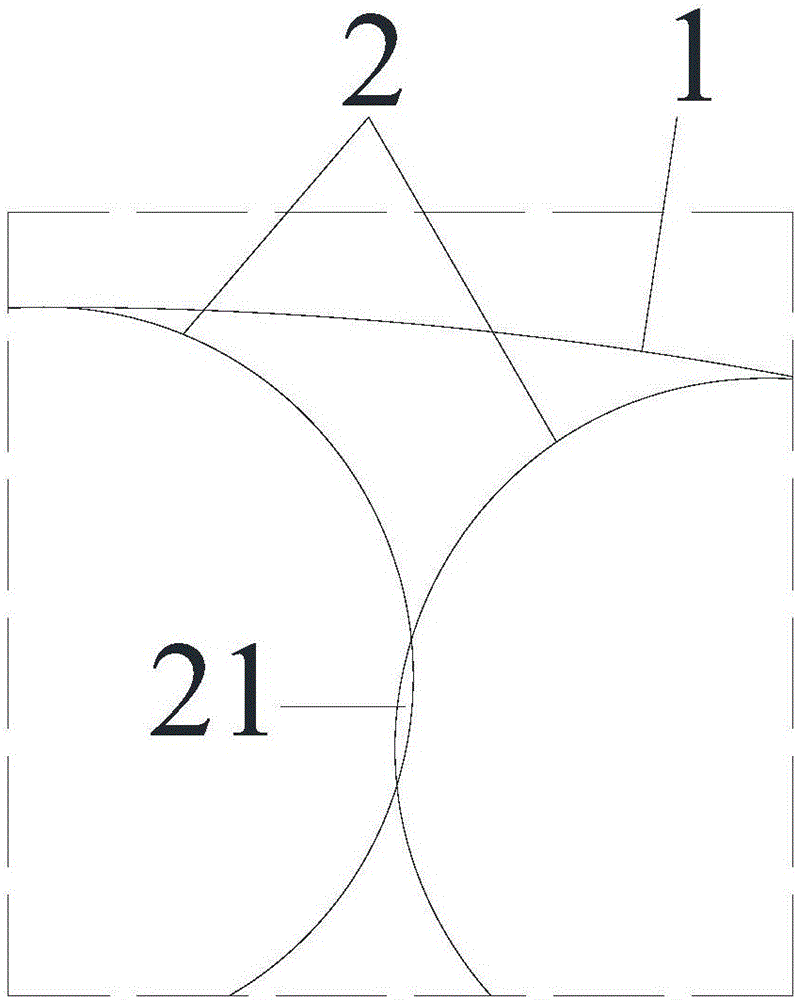

[0034] The span of the tie-rod arch of the Moujia Village Bridge spanning the Tongsan Expressway is 64m. The in-situ cast-in-place column support construction method is adopted. Due to the large span, a temporary pier is required. The foundation of the temporary pier is a pile foundation with a diameter of 1.25m. The pole arch spans the Jinzhong-South railway channel. The pile foundation is located about 1m outside the road shoulder, and the height of the roadbed is about 8m. Normal mechanical construction requires the construction of a working platform, but it will affect the existing line foundation. Mechanical construction is not suitable, and only manual hole-digging piles can be used. method, the rock at the bottom of the pile is gneissic monzogranite with a stress of 800kPa, and ordinary picks cannot be used for construction. At the same time, in order to reduce the impact of normal blasting on the subgrade of Jinzhong South Passage, the following methods are adopted: Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com