Paper scooping device for production of large-sized Chinese art paper

A paper scooping device and large-size technology, which is applied to the field of paper scooping devices for producing large-size rice paper, can solve the problems of difficulty in completing, the overall size of the curtain frame, and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

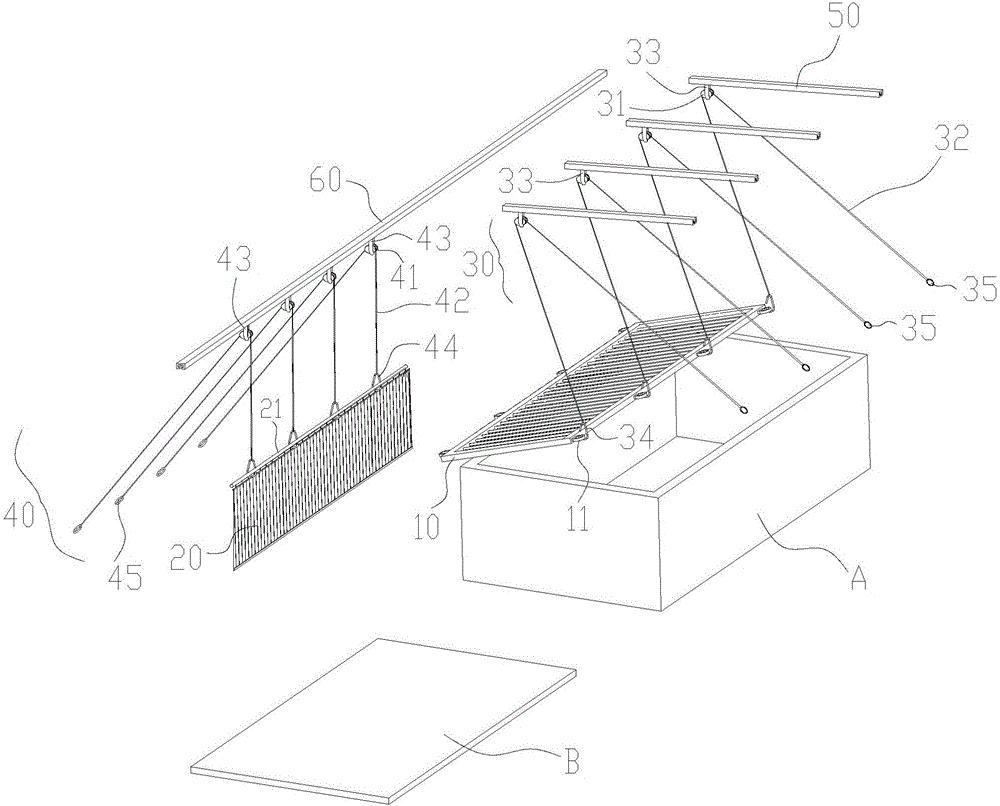

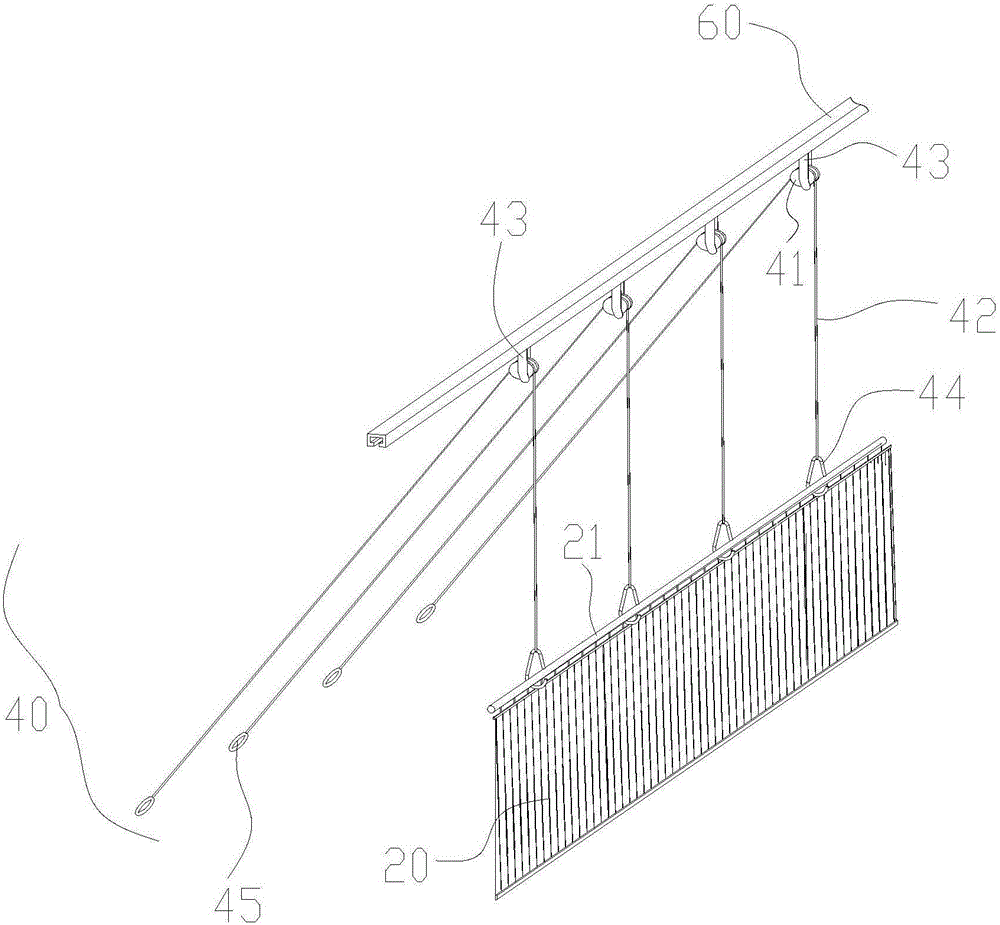

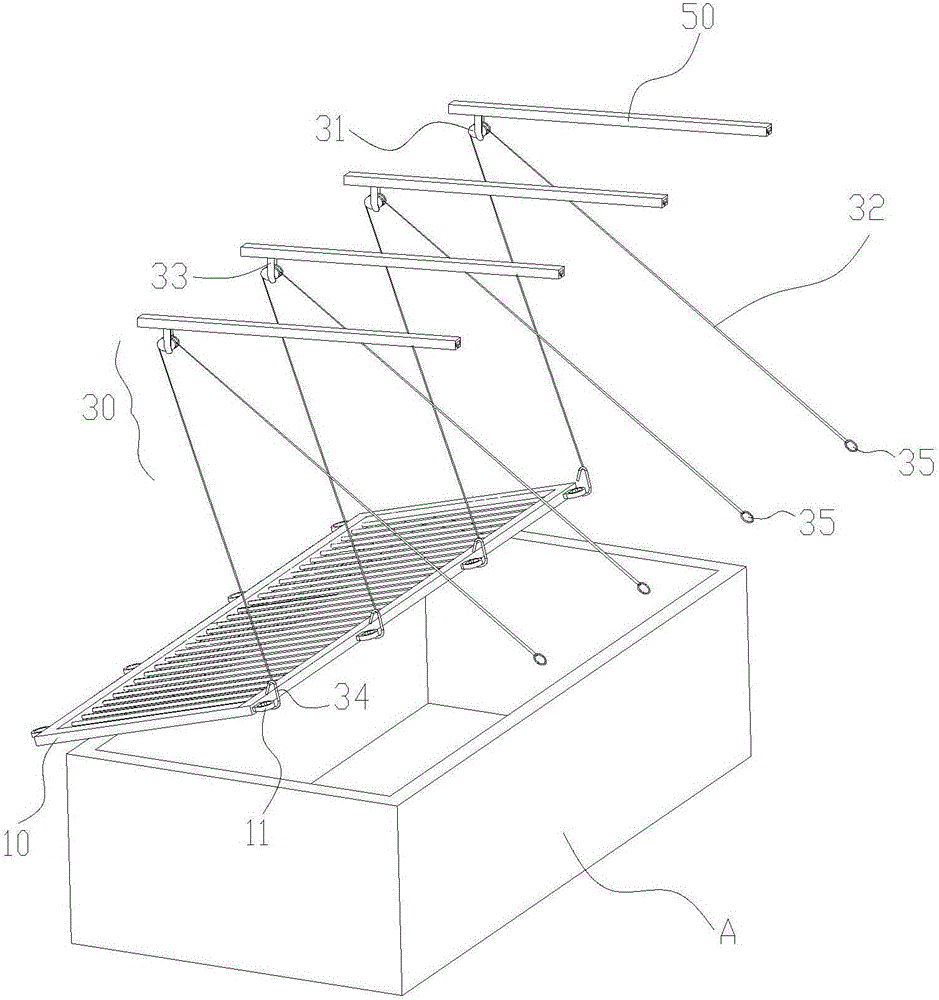

[0012] A paper scooping device for producing large-size rice paper, such as Figure 1-4 As shown, it includes a curtain frame 10 and a paper fishing curtain 20 that can be tiled on the frame surface of the curtain frame 10. The length direction of the curtain frame 10 and the paper fishing curtain 20 are arranged in the same way. The first and second hanging mechanisms 30, 40 that hang on one side of the frame 10 and the paper curtain 20 are suspended, and the first and second suspension mechanisms 30, 40 control the curtain frame 10 and the paper curtain 20 respectively. The up and down movement of the hanging long side; the first hanging mechanism 30 is arranged on the first guide rail 50 arranged horizontally, and the first guide rail 50 controls the first hanging mechanism 30, 40 to move horizontally to drive the curtain frame 10 to or Away from the mouth of pulp pool A. like Figure 1-2 As shown, one long side of the curtain frame 10 can be erected on the slurry tank A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com