Pipeline rehabilitation method based on iron resin spray-coating

A pipeline repair and iron resin technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of long time and high cost, and achieve simple construction operation, cost saving and integration high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

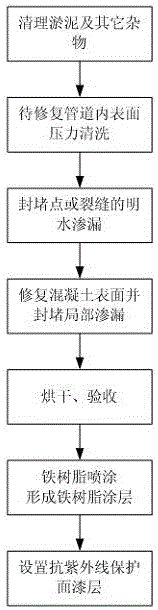

Method used

Image

Examples

Embodiment Construction

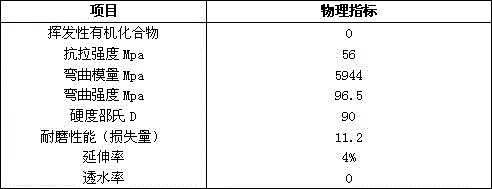

[0024] Iron resin is a new type of resin material with high strength, such as the SprayShield Green II polyurethane coating (English name SprayShieldGreenII) produced by Sprayroq (Sprayroq) in the United States. Volatile, self-forming spray material that protects and restores structural integrity, providing leak control, structural reinforcement and chemical resistance protection for concrete, steel, masonry, fiberglass and other surfaces. Iron resins are excellent for seepage control, high hydraulic loads, and structural restoration of aging water installations. The iron resin can solidify quickly, it starts to gel after about 8 seconds, and reaches a non-shedding state after 1 minute. The initial curing is complete within 30 minutes and the facility is ready to return to service, while curing will continue for 4-6 hours until complete. Once the product application is complete, the newly protected facility can be quickly restored to service.

[0025] The invention fully uti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com