Integrated charging socket

A charging socket and charging connection technology, applied in the field of integrated charging sockets, can solve the problems of rising cost, incompatibility of pin definition and structure definition, affecting vehicle structure design, etc., to save costs, optimize layout, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

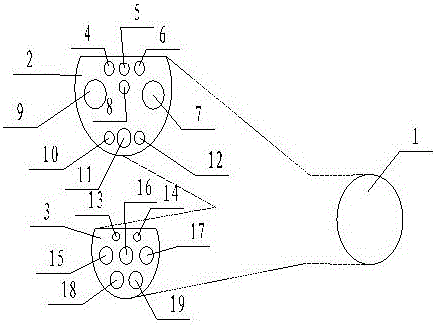

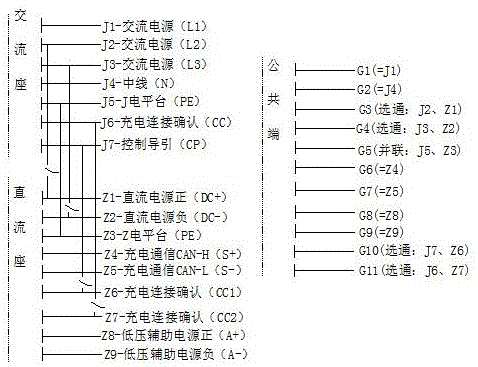

[0012] like figure 1 and figure 2 Shown: an integrated charging socket, including a DC socket 2 and an AC socket 3, characterized in that: the DC socket 2 and the AC socket 3 form a common terminal 1, and the DC socket 2 is provided with 9 Ports, the AC seat 3 is composed of 7 ports, wherein the AC power supply L218 on the AC seat 3 is connected in series with the DC power supply 7 of the DC seat 2, and the AC power supply on the AC seat 3 L319 is connected in series with the DC power negative 9 on the DC seat 2, the J electric platform 5 on the AC seat 3 is connected in parallel with the Z electric platform 11 on the DC seat 2, and the charging on the AC seat 3 The connection confirmation CC18 is connected in series with the control guide 14 on the DC base 2, the charging connection confirmation CC25 on the AC base 3 is connected in series with the charging connection confirmation 13 on the DC base 2, and the charging connection confirmation 13 on the DC base 2 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com