Unmanned inspection system applied to fuel delivery system of power plant

A technology of fuel delivery and inspection system, applied in the field of unmanned inspection system, can solve the problems of low efficiency, long belt conveyor route, high labor intensity, etc., and achieve the goal of reducing dangerous accidents, reducing labor intensity, and preventing and malfunctioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing:

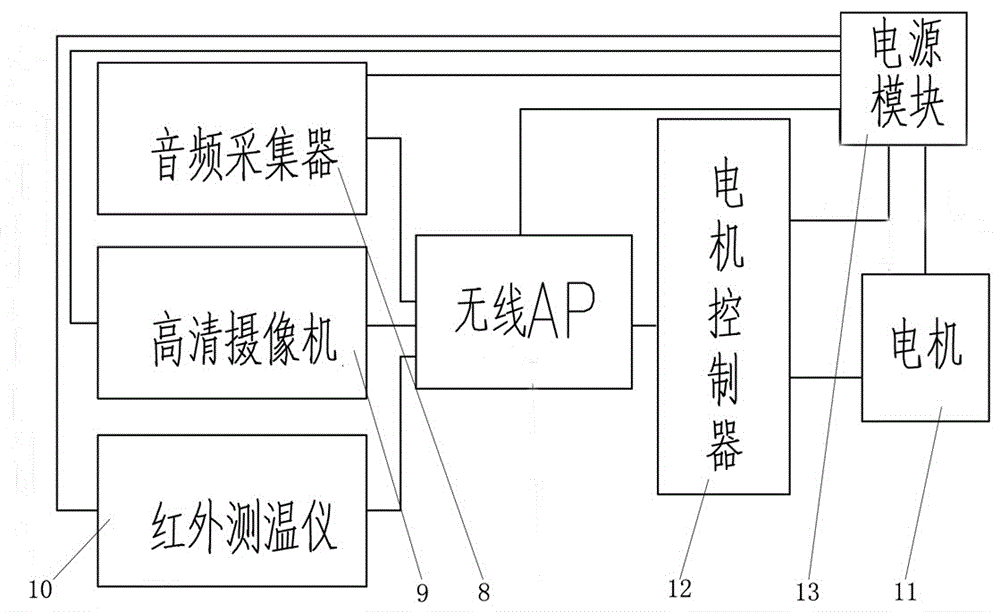

[0016] Such as figure 1 As shown, an unmanned inspection system applied to the fuel delivery system of a power plant includes a fuel delivery belt 1, a data acquisition end moving track 2 is set above the fuel delivery belt 1, and a data acquisition end 3 is hung on the data acquisition end through a sliding wheel 14. On the moving track 2 of the data collecting end, the sprocket meshes the chain between the data collecting end and the moving track of the data collecting end, and the sprocket drives the sliding wheel to move along the moving track of the data collecting end. AP4, the data collection terminal 3 is connected wirelessly to the wireless AP4, the wireless AP4 is connected to the switch 5 arranged in the monitoring room through a wired network, and the switch 5 is connected to the monitoring host 6; the power supply of the data collection terminal 3 is drawn fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com