Method for detecting methanol in light petroleum

A technology for light petroleum and detection methods, which is applied in the preparation of test samples, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problems of large instrument volume and detection limit. High cost, high cost, etc., to achieve the effect of low detection cost, low condition requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

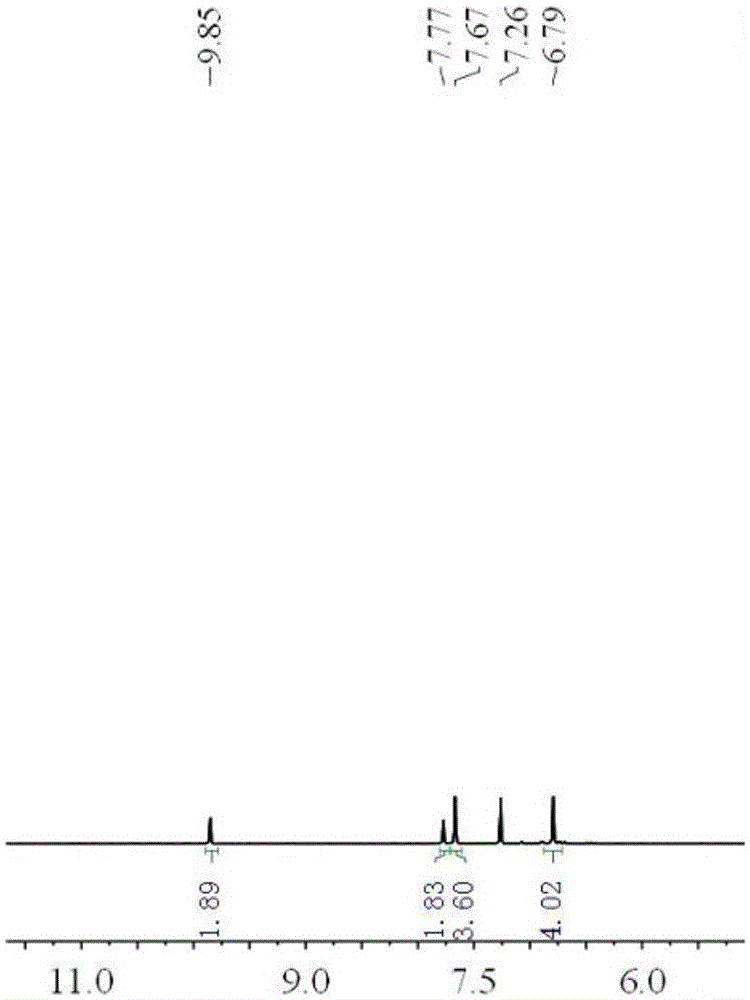

[0043] The detection method of methyl alcohol in described light oil specifically comprises the following steps:

[0044] Step a, take 100 parts by volume of light petroleum, add 10 parts by volume of distilled water, mix uniformly and leave to separate to obtain an oil phase and an aqueous phase;

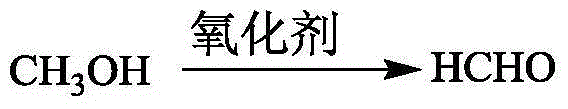

[0045] Step b, take 1 volume part of the water phase, add 1.5 volume parts of 0.19mol / L potassium permanganate aqueous solution, mix well, heat until the solution appears brick red turbid, add 1 volume part of 0.45mol / L oxalic acid aqueous solution , shake until the solution is transparent and bright red, so that the excess potassium permanganate is completely neutralized;

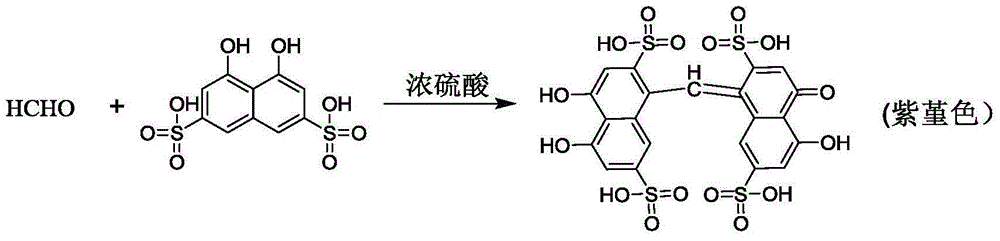

[0046] Step c, add 1 volume part of 0.16mol / L color-changing acid aqueous solution to the solution obtained in step 2, stir until the solution is light yellow, then add 2 volume parts of concentrated sulfuric acid, if it is observed that purple purple color appears in the solution then It means that the methan...

example 2

[0075] A method for detecting methanol in light petroleum, comprising the following steps:

[0076] Step 1. Take 80 parts by volume of light petroleum, add 12 parts by volume of distilled water, mix evenly and leave to separate to obtain an oil phase and an aqueous phase;

[0077] Step 2: Take 1.2 parts by volume of the water phase, add 2 parts by volume of 0.25mol / L potassium permanganate aqueous solution, mix well, heat until the solution appears brick red and turbid, add 2 volume parts of 0.54mol / L oxalic acid aqueous solution , shake until the solution is transparent and bright red, so that the excess potassium permanganate is completely neutralized;

[0078] Step 3, add 1.2 parts by volume of 0.19mol / L aqueous solution of color-changing acid to the solution obtained in step 2, stir until the solution is light yellow, then add 2.5 parts by volume of concentrated sulfuric acid, if it is observed that purple viola appears in the solution then It means that the methanol cont...

example 3

[0087] A method for detecting methanol in light petroleum, comprising the following steps:

[0088] Step 1. Take 120 parts by volume of light petroleum, add 8 parts by volume of distilled water, mix evenly, and leave to separate to obtain an oil phase and an aqueous phase;

[0089] Step 2: Take 0.8 parts by volume of the water phase, add 1 part by volume of 0.13 mol / L potassium permanganate aqueous solution, mix well, heat until the solution appears brick-red turbid, add 1 volume part of 0.36 mol / L oxalic acid aqueous solution , shake until the solution is transparent and bright red, so that the excess potassium permanganate is completely neutralized;

[0090] Step 3, add 0.8 parts by volume of 0.12mol / L aqueous solution of color-changing acid to the solution obtained in step 2, stir until the solution is light yellow, then add 1.5 parts by volume of concentrated sulfuric acid, if it is observed that purple purple color appears in the solution then It means that the methanol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com