Extraction structure and liquid pretreatment device

An extraction and liquid technology, applied in the fields of extraction structures and liquid pre-treatment devices, can solve the problems of cumbersome operation steps, inaccurate detection results, and excessive waste generation, and achieve the effects of simple operation steps and accurate component detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

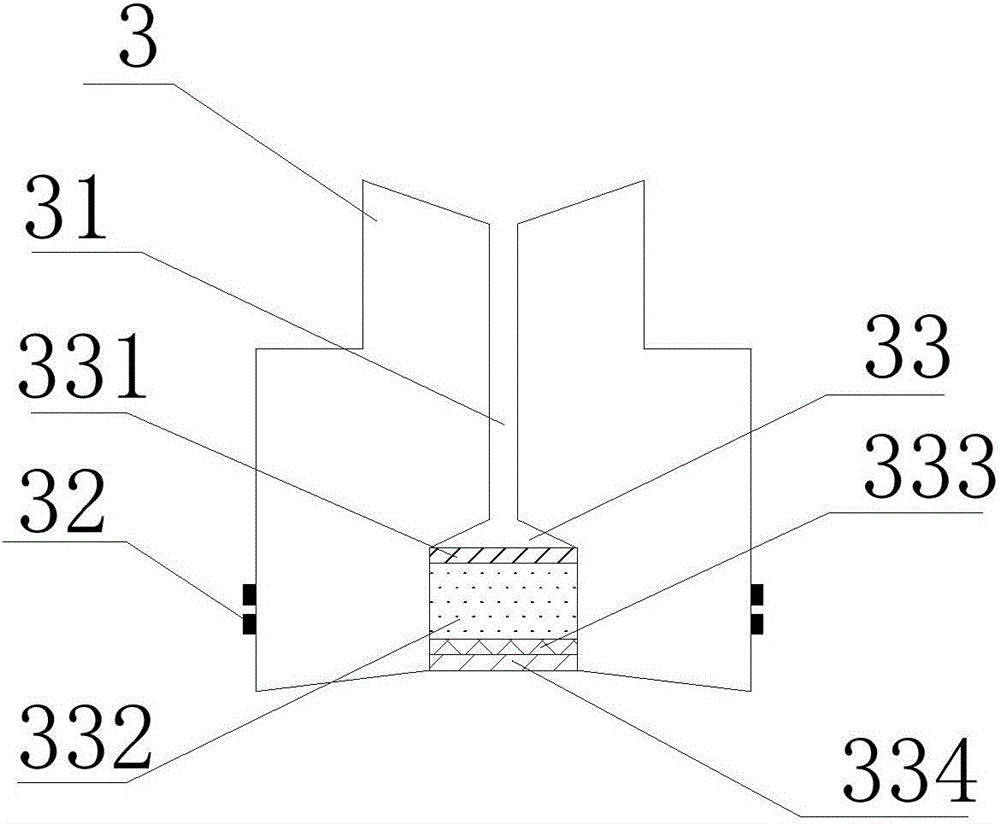

[0044] figure 1 Schematic diagram of the structure of the extraction structure provided for the embodiments of the present invention; as figure 1As shown, the extraction structure provided in this embodiment includes an extraction structure body 3, a cavity 33 and a first hole 31 are arranged inside the extraction structure body 3, and a first filter 333 and an extraction agent layer 332 are arranged in sequence inside the cavity 33 And porous filter disc 331;

[0045] The inside of the first filter sheet 333 is provided with an expansion agent to form a filter sheet that is sealed with water. The filter sheet can pass through an organic solvent. cannot pass;

[0046] The extraction structure can achieve the effects of water blocking, purification and filtration through the arrangement of the first filter 333 , extractant layer 332 and porous filter 331 , and can realize the process of liquid-liquid distribution and solid-phase extraction in one step.

[0047] In the option...

Embodiment 2

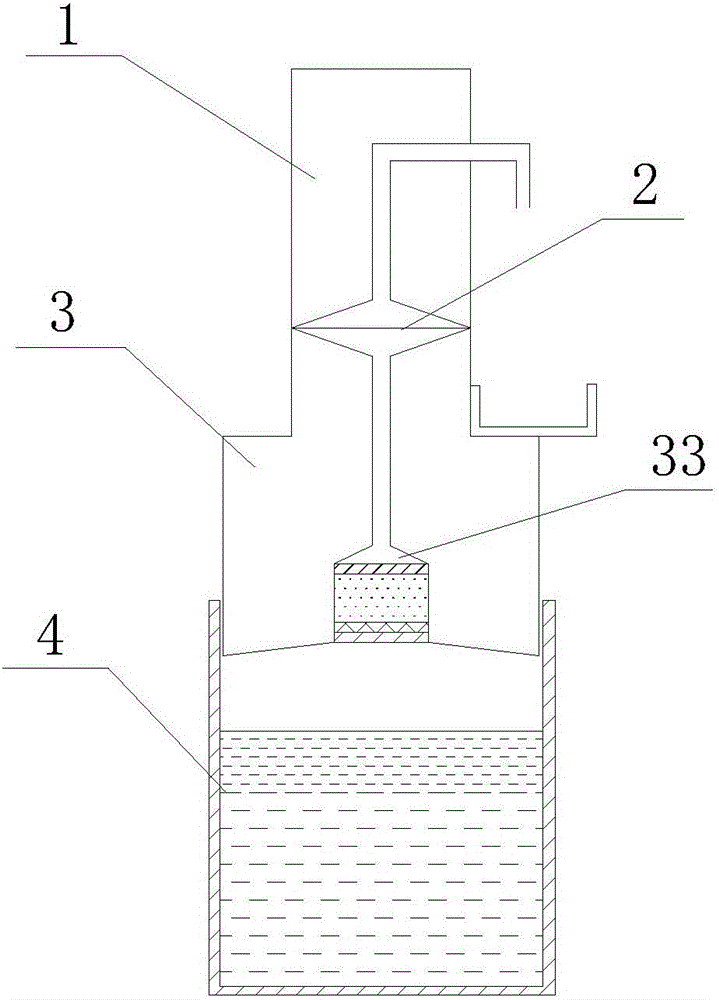

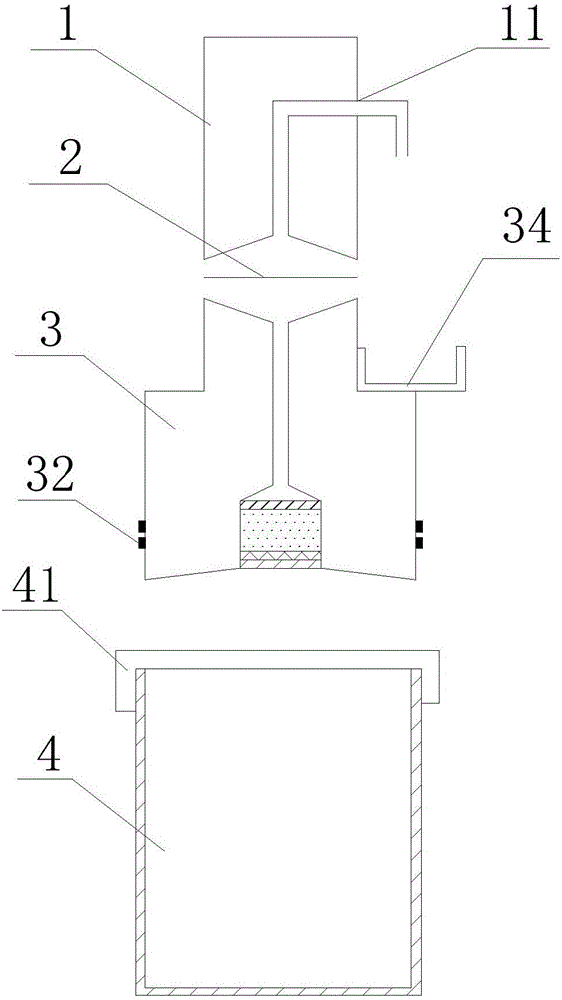

[0062] figure 2 Schematic diagram of the structure of the liquid pretreatment device provided by the embodiment of the present invention; image 3 for figure 2 An exploded view of the liquid pretreatment device; as Figure 2-3 As shown, the liquid sample pretreatment device provided in this embodiment includes a storage tank 4 and a transfer device 1, the transfer device 1 is clamped with the extraction structure, the extraction structure extends into the storage tank 4, and the storage tank 4 has been injected with an organic solvent and water, the organic solvent and water are immiscible and layered; by pressing the transfer device 1, the upper layer organic solvent inside the storage tank 4 enters the extraction structure, and the pressure is continued. When the water layer contacts the first filter sheet 333 that is sealed with water, the second Once the filter sheet 333 is blocked, the aqueous solution cannot pass through, which facilitates the liquid transfer of the ...

Embodiment 3

[0071] Figure 4 A schematic structural view of a liquid pretreatment device provided in another embodiment of the present invention; as Figure 4 As shown, the liquid pretreatment device provided in this embodiment includes a storage tank 4 and a transfer device 1. The transfer device 1 is clamped with the extraction structure, and the extraction structure extends into the storage tank 4. The storage tank 4 has been injected with organic solvents and Water, organic solvents and water are immiscible and stratified; by pressing the transfer device 1, the upper organic solvent inside the storage tank 4 enters the extraction structure, and the pressing is continued. When the water layer touches the first filter sheet 333 that is sealed with water, the first When the filter sheet 333 is blocked, the aqueous solution cannot pass through, which facilitates the liquid transfer of the organic solvent containing the components to be measured; the four steps of liquid-liquid extraction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com