Hydraulic system component reliability test device and method including environment field

A hydraulic system and test device technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as low reliability hydraulic system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

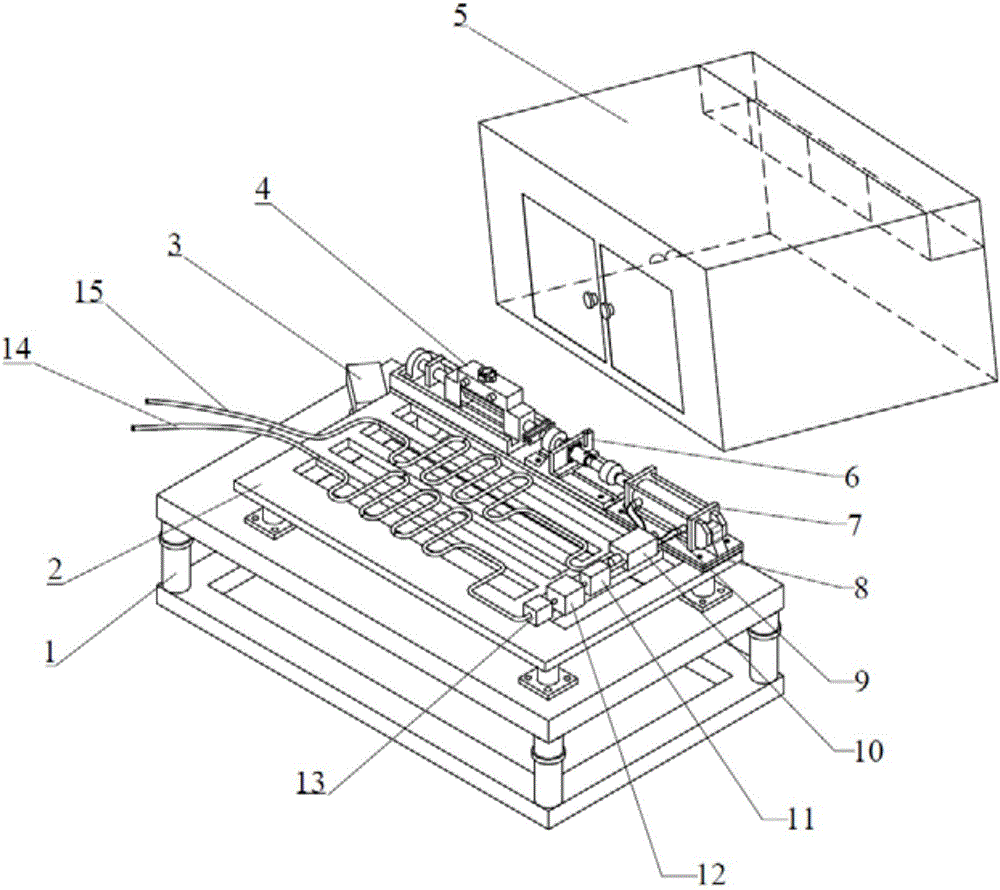

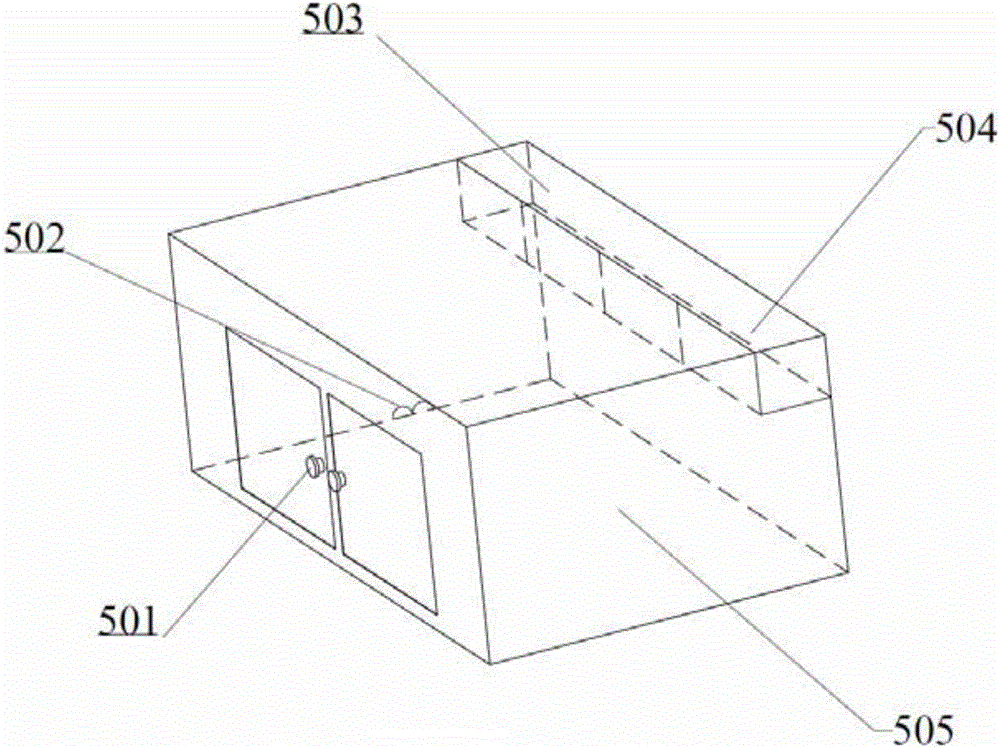

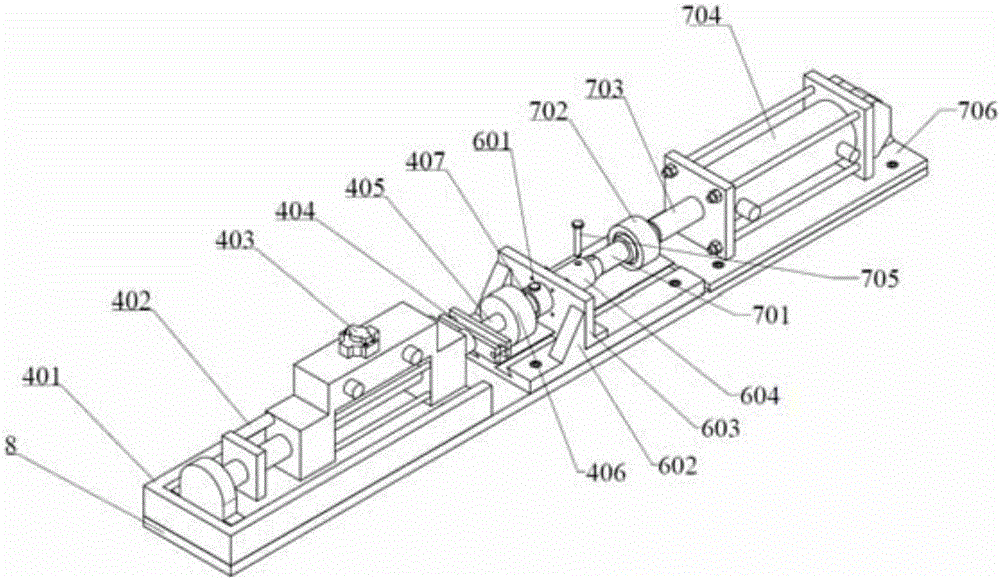

[0085] The three-dimensional vibration platform 1 is fixed on the ground by anchor bolts, the monitoring device 3 is fixed on the upper surface of the three-dimensional vibration platform 1, the support frame 2 is fixed on the upper surface of the three-dimensional vibration platform 1, the electro-hydraulic servo device 4, the connecting device 6 and the hydraulic cylinder The component 7 is fixed on the support frame 2 after being aligned by the bottom plate 8. The three-position four-way electromagnetic reversing valve 10, the temperature sensor 11, the flow sensor 12, and the pressure sensor 13 are installed on the upper surface of the support frame 2. The hydraulic cylinder The component 7 and the three-position four-way electromagnetic reversing valve 10 are connected through a connecting oil pipe 9 , and the temperature and humidity control box component 5 is installed on the upper surface of the three-dimensional vibration table 1 .

[0086] The three-dimensional vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com