Through floor protection sleeve

A protective cover and floor technology, applied in pipeline protection, pipeline protection through thermal insulation, thermal insulation, etc., can solve problems such as temperature rise in the working environment, heat loss, inability to coat thermal insulation materials, etc., to increase stability and prevent heat from spreading. , Improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

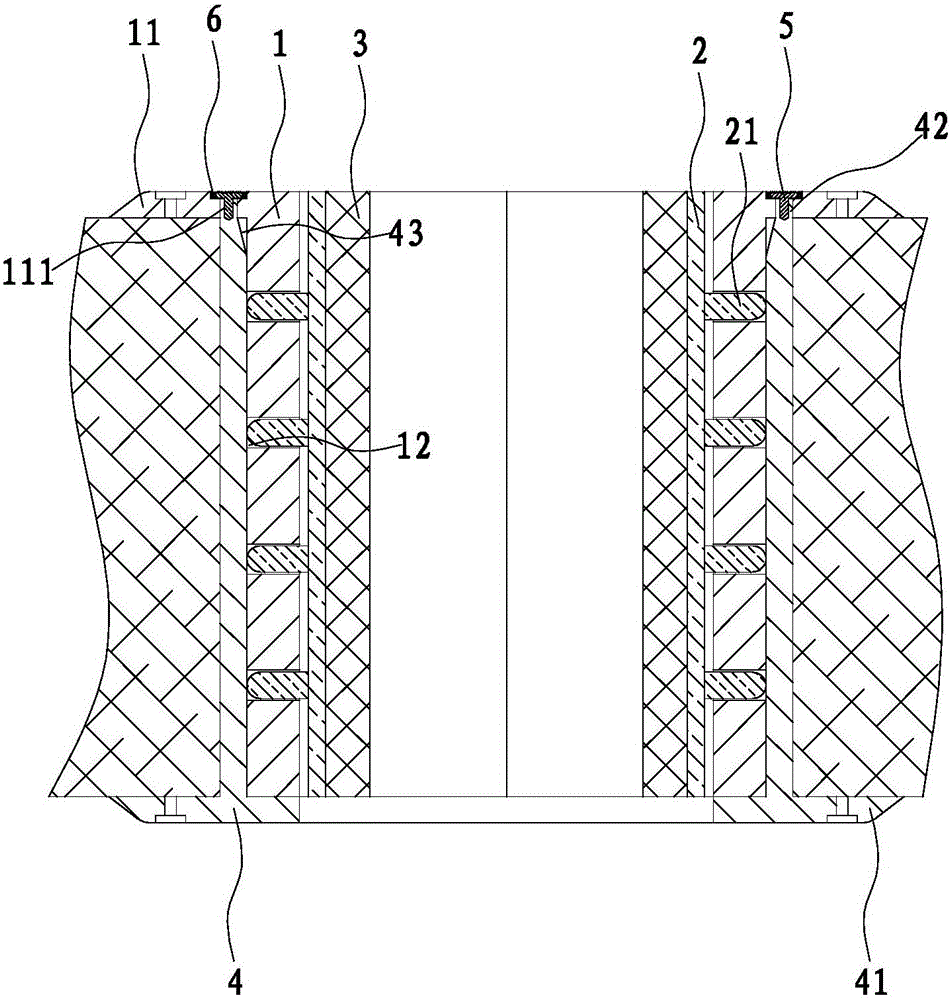

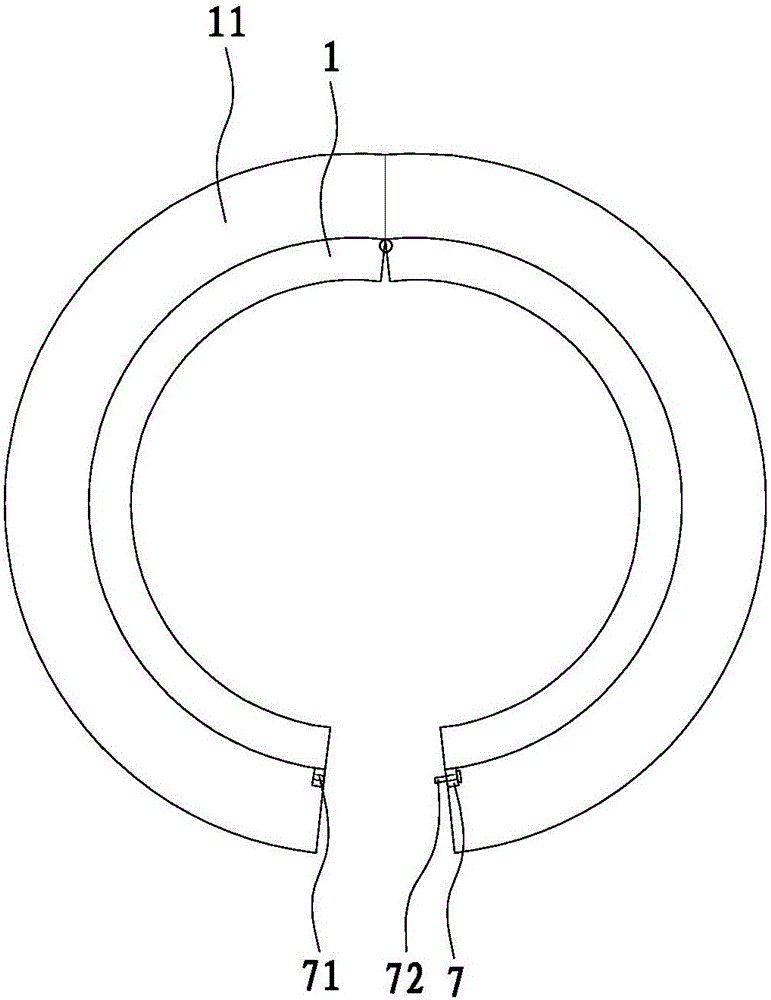

[0012] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0013] refer to figure 1 , figure 2 , the present embodiment provides a floor protection cover, including two semi-cylinders 1 axially hinged along the outside of the circumference, a semi-circular support plate 2 arranged in the semi-cylinder 1, and an insulating material provided on the support plate 2 3. The cover is arranged on the locking cover 4 outside the semi-cylinder 1. Each semi-cylinder 1 is provided with a first step 11 for locking to the floor through bolts. On the second step 41 of the floor, a plurality of pressing holes 12 are evenly distributed on the circumference of each semi-cylinder 1, and a plurality of protrusions 21 corresponding to the pressing holes 12 are provided on the support plate 2. The column 21 is installed in the pressing hole 12 , and the end of the protruding column 21 protruding from the semi-cylinder 1 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com