Belt Assisted Squeeze Cone Belt Transmission

A technology of speed change device and transmission belt, applied in the field of transmission speed change, can solve the problems of affecting transmission efficiency and transmission capacity, affecting the life of steel belt, easy to slip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

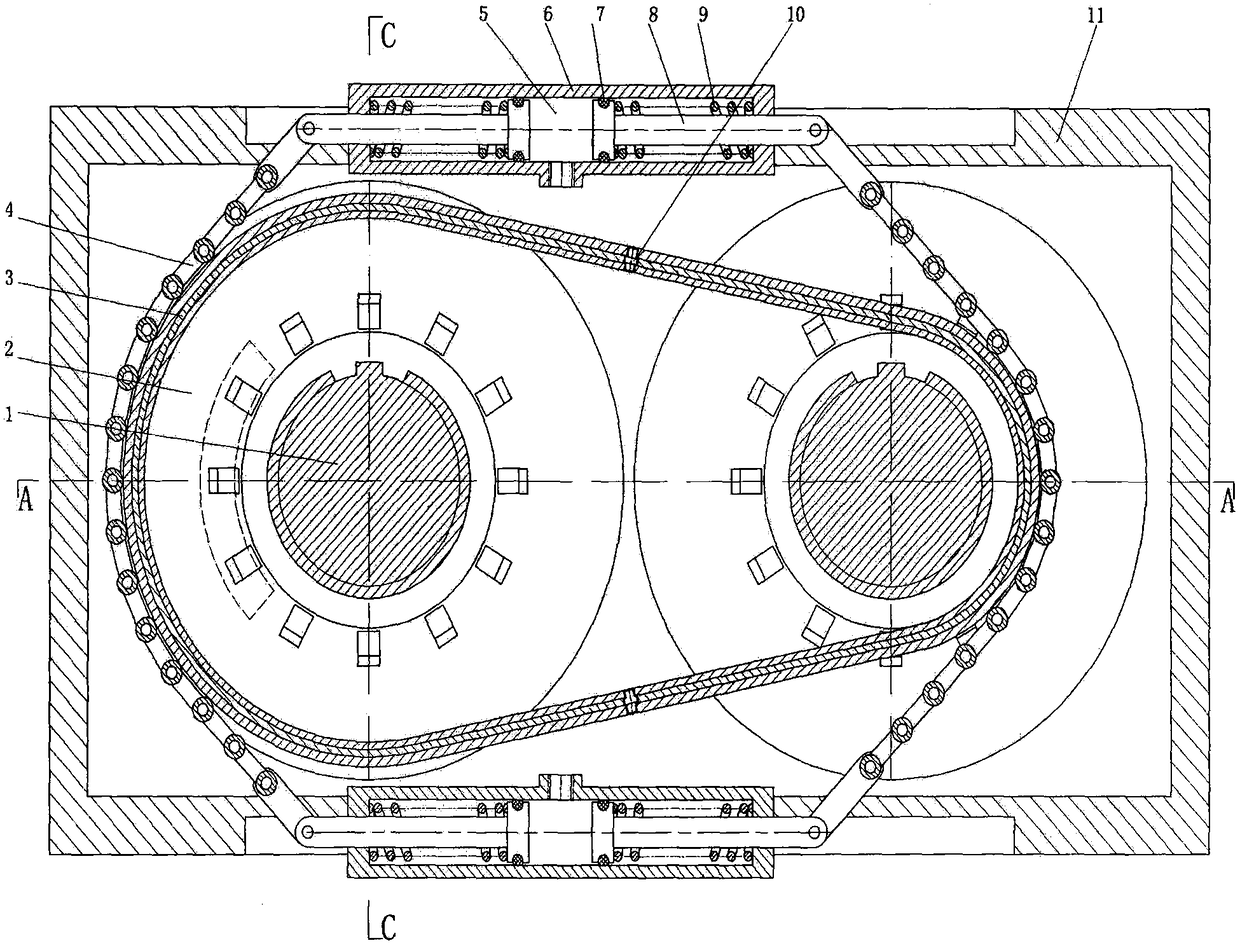

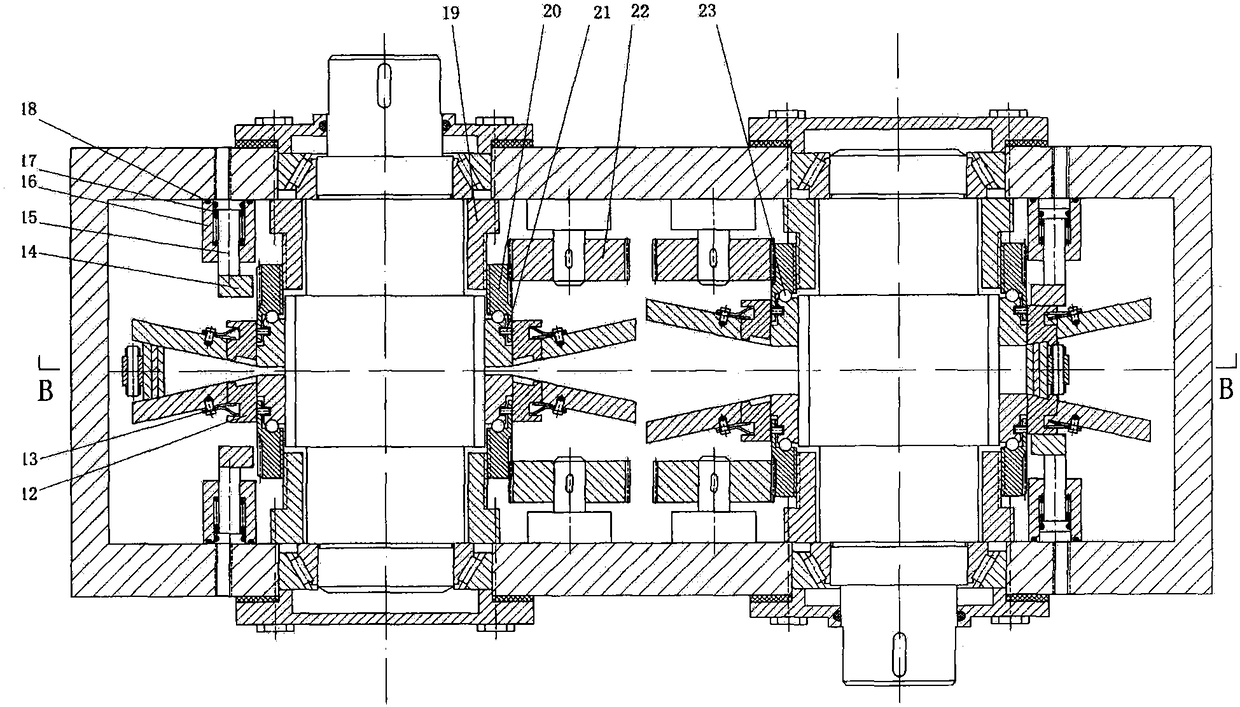

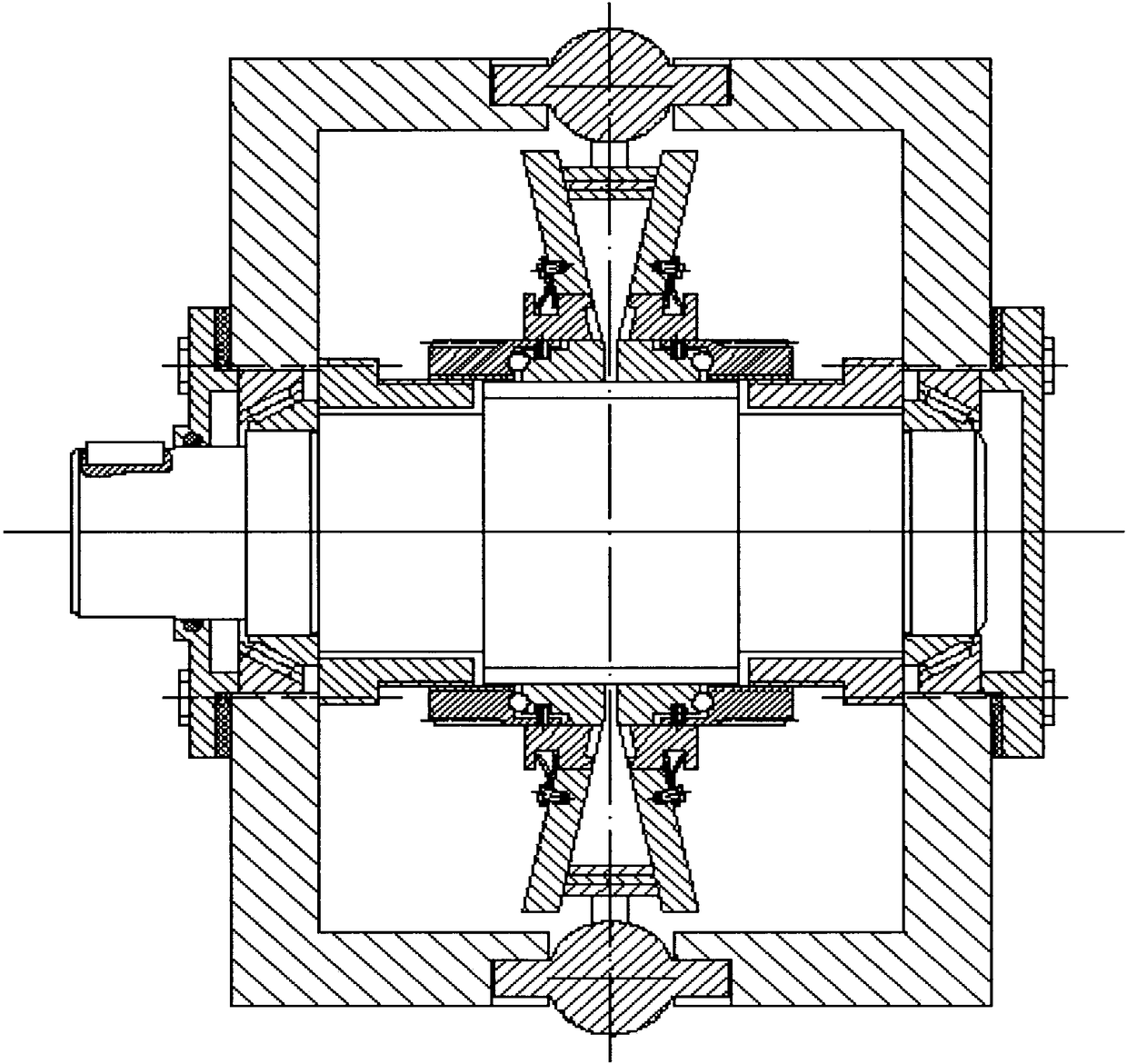

[0014] The basic scheme of the patent of the present invention is to set a back force mechanism on the outer back side of the drive belt of the conical-disk-belt type transmission and the conical-disk contact section or set a side force mechanism on both sides to limit the relative sliding between the drive belt and the conical-disk cone surface; The transmission belt is clamped between two sliding cones on the same spline shaft and arranged opposite to each other, and connects two sets of cones; under the action of the movement control mechanism of the cones, with the movement of the coaxial cones, the transmission belt will move between the cones The diameter of the tapered surface can be reduced, and the transmission ratio can be changed continuously or at a fixed value. In order to clearly illustrate the technical features of this solution, the following describes this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0015...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com