Manufacture method of cotton series healthy pajamas with sleep-promoting function

A technology that promotes sleep and pajamas, applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of fragrance disappearance and short fragrance retention time, so as to promote sleep, broad market prospects, improve performance and added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Preparation of flavor microcapsules: using melamine resin as the wall material and lavender extract as the core material, according to m core: m The wall ratio is 1:1. Based on the in-situ polymerization method, the essence microcapsules are prepared at a temperature of 65°C for 4 hours.

[0016] (2) Finishing liquid formula: 40g of lavender essence microcapsules, 40g of low-temperature fixable water-based polyacrylate adhesive, 4g of silicone softener, 2g of non-ionic penetrant JFC, add water to 1kg.

[0017] (3) Finishing process: the fabric is made of 50% regenerated cellulose fiber, 45% polyester fiber, 5% spandex, 40 pieces of TR50 / 50 frame cloth, and the weight is 175; the process conditions are: rolling rate 80%; drying The temperature is 80°C, and the time is 8 minutes; the baking temperature is 120°C, and the time is 2 minutes.

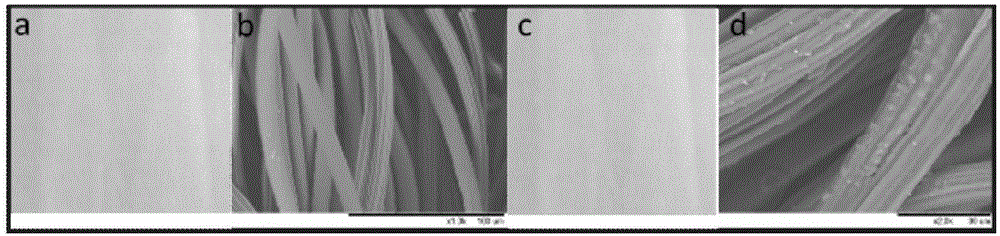

[0018] figure 2 Surface morphology of fabrics before and after finishing for lavender fragrance microcapsules. Among them, a...

Embodiment 2

[0022] (1) Preparation of essence microcapsules: using melamine resin as the wall material and jasmine extract as the core material, according to m core: m The wall ratio is 3:4. Based on the in-situ polymerization method, the fragrance microcapsules are prepared at a temperature of 70° C. and kept for 3 hours.

[0023] (2) Finishing liquid formula: 45g of jasmine essence microcapsules, 40g of low-temperature fixable water-based polyurethane adhesive, 4g of silicone softener, 2g of non-ionic penetrant JFC, add water to 1kg.

[0024] (3) Finishing process: 100% cotton knitted fabric is selected; the process conditions are: 100% rolling rate; drying temperature 85°C, time 10 minutes; baking temperature 125°C, time 3 minutes.

[0025] Figure 4 Surface morphology of fabrics before and after finishing for jasmine essence microcapsules. Among them, a-photo of the original fabric; b-SEM picture of the original fabric; c-photo of the finished fabric; d-SEM picture of the finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com