An all-in-one machine for tape slitting, rib detection and coding

An all-in-one machine and coding machine technology, applied in typewriters, printing devices, winding strips, etc., can solve the problems of inconvenient and delayed removal of residual ribs, insufficient compactness of procedures and equipment, and low efficiency, and achieve manual removal of ribs The effect of convenience and speed, accurate detection and guaranteed synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

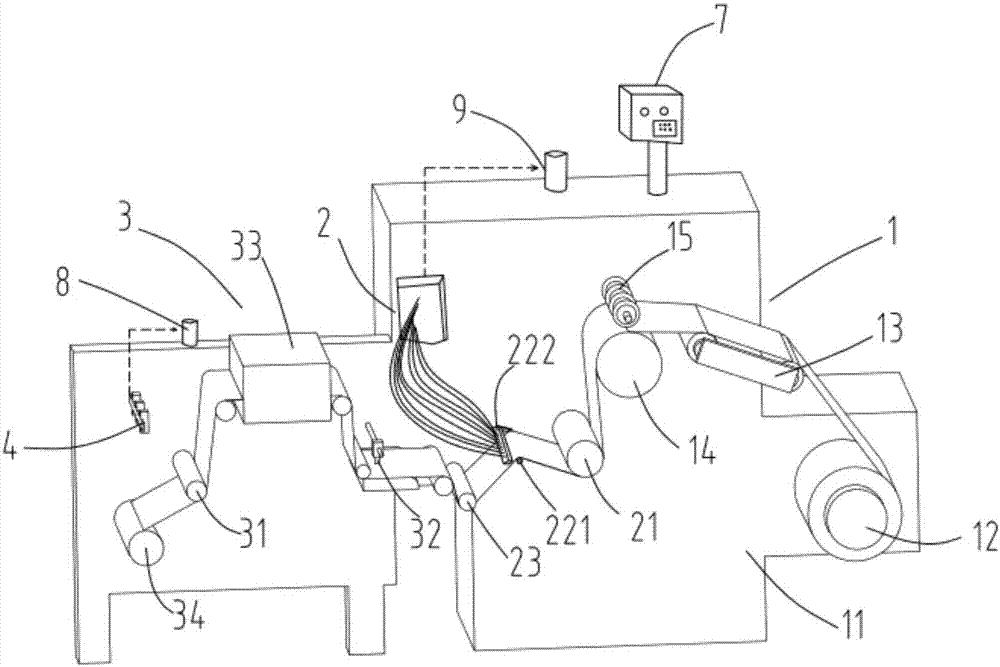

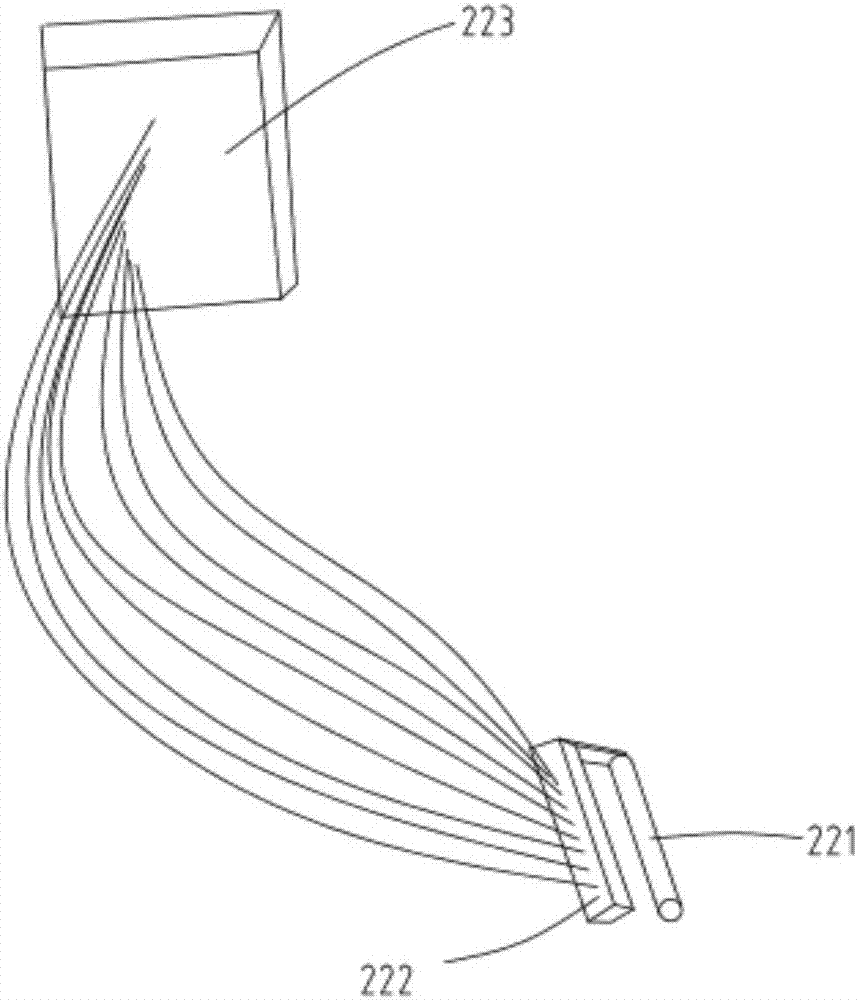

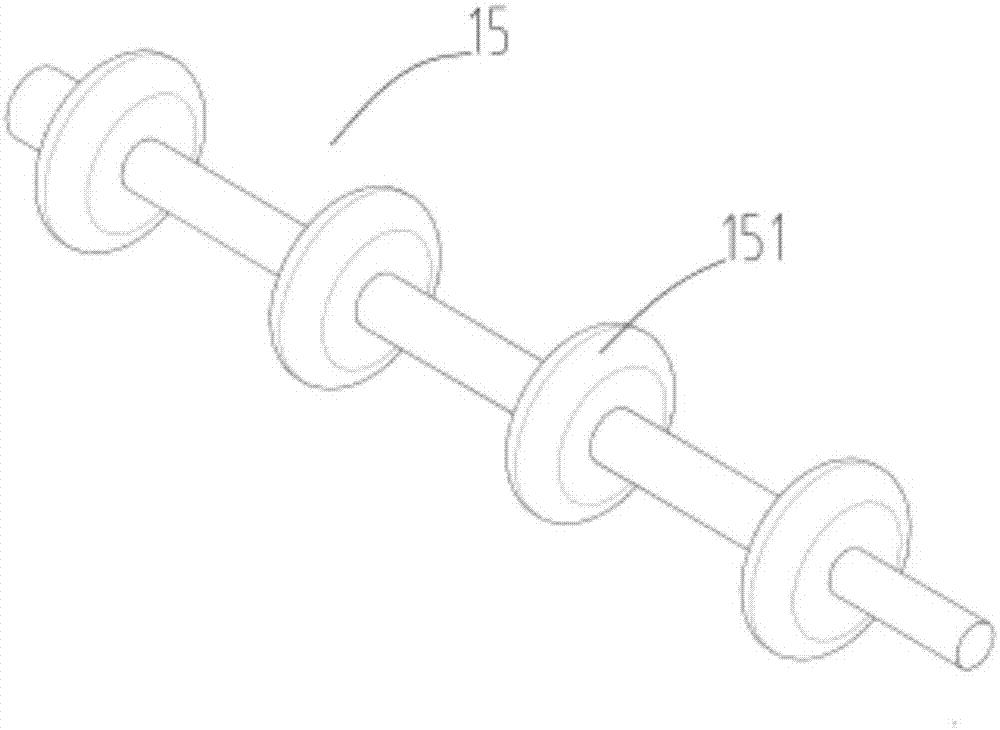

[0028] figure 1 It is a structural schematic diagram of an all-in-one machine for tape striping, rib detection and coding, figure 2 It is a structural schematic diagram of an all-in-one detection device for tape striping, rib detection and coding, image 3 It is a structural schematic diagram of a cutting roller of an all-in-one machine for tape slitting, rib detection and coding. Such as figure 1 , figure 2 , image 3 As shown, an all-in-one machine for tape slitting, rib detection and coding includes a tape slitting part 1, a rib detection part 2 and a coding part 3; the tape slitting part 1 includes a tape slitting machine frame 11; one side of the tape slitting machine frame 11 is respectively equipped with a total raw material roller 12, an adjustable double guide roller 13, a pressure roller 14 and a cutting roller 15 from bottom to top; the rib detection part 2 includes Lead-in roller 21, lead-out roller 23 and rib detection device 22 arranged between the two; sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com