Device for automatically counting express items on conveyor

An automatic counting and conveyor technology, applied in conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of high installation and use costs, high environmental requirements, and high costs, and achieve easy installation and maintenance. Low environmental requirements , the effect of strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

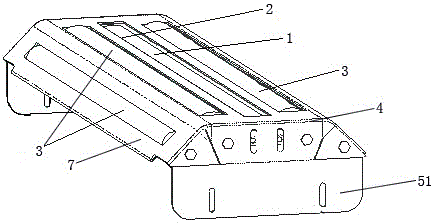

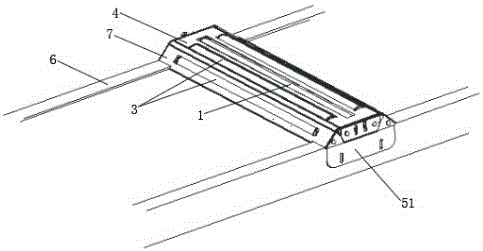

[0033] refer to Figure 1 to Figure 2 , the automatic counting device includes an infrared optical eye array 1, a protective plate 2, a roller 3, a control panel, and a mounting bracket 4.

[0034] Further, the infrared optical eye array 1 is a continuous reflective infrared optical eye array, the infrared optical eye array 1 is composed of infrared emitting devices and receiving devices, and the infrared optical eye array 1 is roughly in the shape of a cuboid. Composed of infrared emitting devices and receiving devices, the diodes are arranged in a row with a certain gap.

[0035] Further, the control panel has a piece counting module, a wireless transmission module, a speed control module, and an information processing module, and the piece counting module, the wireless transmission module, the speed control module, and the information processing module are electrically connected, and the control panel is built in in the automatic counting device.

[0036] Further, there a...

Embodiment 2

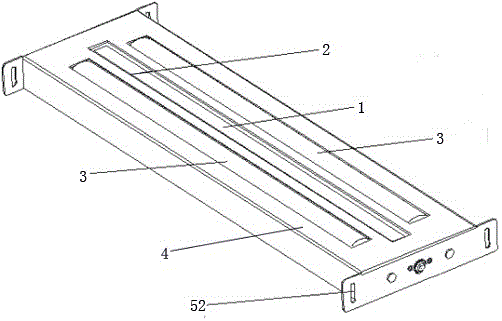

[0051] refer to Figure 3 to Figure 4 , including an infrared optical eye array 1, a protective plate 2, a roller 3, a control panel, a mounting bracket 4, and a connecting bracket 52.

[0052] On the basis of Example 1, Figure 3 to Figure 4 When connecting two conveyors 6, the specific use state diagram of the automatic counting device of the technical solution, when connecting two conveyors 6, the connecting bracket 52 is image 3 or Figure 4 As shown, further, when two conveyors 6 are connected, the mounting bracket 5 does not have an inclined bracket 7, and the automatic counting device as a whole directly realizes seamless connection with the two conveyors 6, and its protective plate 2, roller 3 is consistent with the horizontal position of the conveyor belt of the conveyor 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com