Finger pasting type industrial material bag separating device

A separation device and patch device technology, applied in packaging and other directions, can solve the problems of inconvenient packaging and difficult separation of bag mouths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

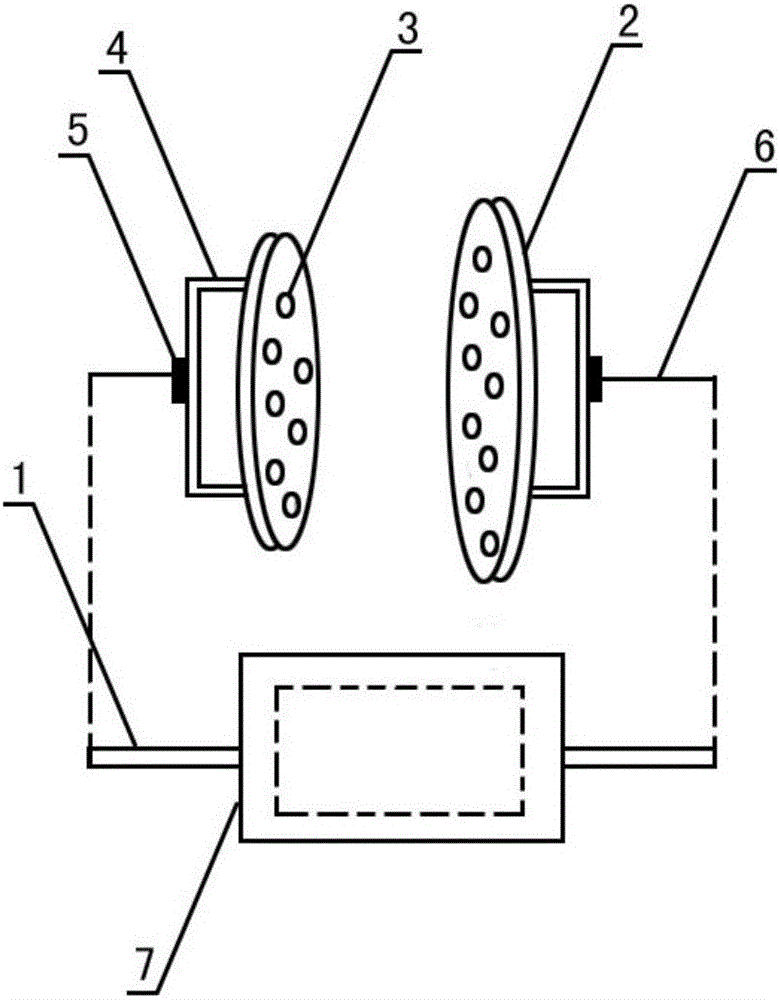

[0012] Embodiment: as shown in the accompanying drawing. A separation device for finger-sticking industrial material bags, including a set frame (1), the frame (1) is divided into two parts, the index finger and the thumb, and the two ends are equal in structure design, including a soft rubber patch device (2) , raised small hole device (3), finger guard ring (4), connection module (5), connected with the wrist cover device (7) through the stretching device (6), when using, put the frame body (1) on the corresponding finger On the surface, by squeezing the film, the surface of the industrial bag forms friction, so as to achieve the effect of rapid separation.

[0013] The utility model relates to a separating device for finger-sticking industrial material bags. The soft rubber patching device (2) has a double-layer structure, the inner wall is close to the cortex, and a thin water-absorbing sponge pad is arranged in the middle, which has good water absorption.

[0014] A sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com