Track flat car and seamless cross steel track for use with it

A rail flat car and track technology, applied in the field of rail flat cars, can solve problems such as bumps, precision object quality, hidden safety hazards, and misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

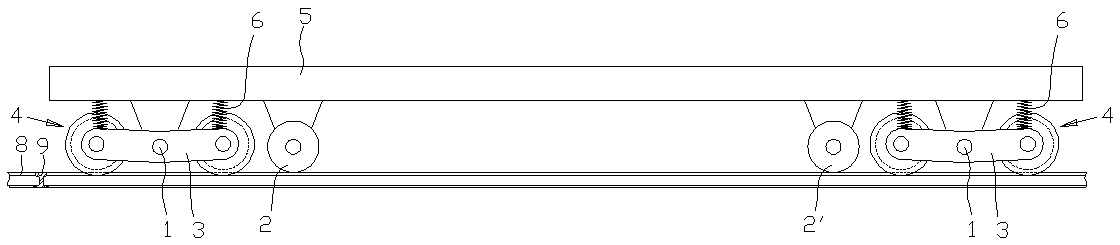

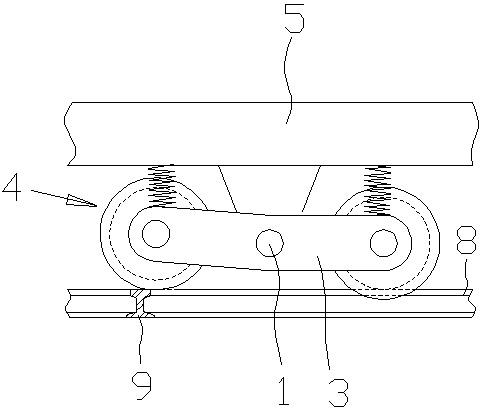

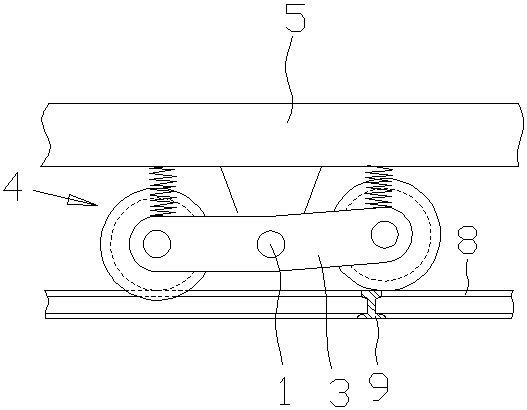

[0017] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 7 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0018] The present invention is a rail flat car, comprising a body 5, a pair of front rollers 2 and a pair of rear rollers 2' arranged under the body 5, two parallel steel rails are arranged under the front and rear rollers 2, 2' , the front and rear rollers 2, 2' have the same size and their outer peripheries are cylindrical, the width w of the front and rear rollers 2, 2' is greater than the width of the steel track, in front of the two front rollers 2, the two The rear of each rear roller 2' is provided with a guide device, and the guide device includes a shaft 1 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com