Safety covering device for moving gap for articulated vehicle

A technology for covering devices and gaps, applied in vehicle parts, transportation and packaging, traction connectors, etc., can solve the problems of inconvenient adjustment and disassembly, insufficient support, insufficient stability, etc., to achieve stable and reliable structure, convenient use, push-pull Sexual performance enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

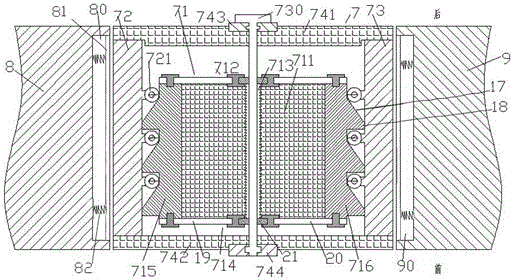

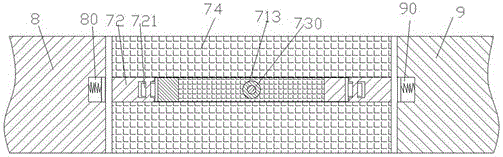

[0008] Combine below Figure 1-2 The present invention will be described in detail.

[0009] According to an embodiment, a movable gap safety covering device 7 for a towed vehicle is used to cover the movable gap between the first part 8 and the second part 9 that can be movably connected together, the covering device 7 Including the elastic material main body 74 and the bearing block driving elastic assembly 71 that can move horizontally in the front and rear directions in the cavity in the elastic material main body 74, the bearing block driving elastic assembly 71 includes an elastic pressing force transmission part 711 , the two wedge-shaped tooth parts 715, 716 symmetrically fixed on both sides of the elastic pressing force transmission part 711 and fixedly arranged in the inner part of the central axis of the elastic pressing force transmission part 711 through the peripheral fixed teeth. The threaded sleeve 713, the front and rear sides of the bearing block driving ela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com